Catalog excerpts

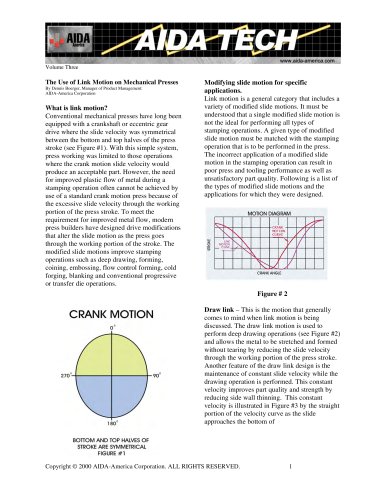

Volume Eight NEW DEVELOPMENTS IN PRESS SLIDE GUIDE SYSTEMS 6 POINT SLIDE GUIDE By Dennis Boerger, Product Manager AIDA-America Corporation The function of the slide guide system in a metal forming press is to ensure the alignment of the punch and die during the cutting, bending, drawing, coining, extruding, etc. which is being performed on the metal as the die closes. Only the press guiding system can accomplish this feat. Die guide posts and bushings are meant to be used during construction, maintenance and setting of the die. They are not of sufficient size to act as the primary guiding system for a stamping operation and will soon need replacement if not supported by a good press slide guiding system. Press slide guide systems have experienced incremental improvements over the last 75 to 100 years. Beginning with molten babbit being poured between the slide and press columns and operating without lubrication then progressing to “V” type and 45 degree gibs (see Figure #1) with grease lubrication. Next came the 6 and 8 point square guides with grease or lost oil lubrication and finally the addition of high volume re-circulating oil (see Figure #2 and #3). V-TYPE GIBBING Figure #2 8 POINT SLIDE GUIDE Figure #3 The common thread that winds through each of these improvements is the need to more accurately guide the press slide through the entire stroke. The continual improvement in slide guiding allows for tighter tolerances in the manufacture of dies that produce ever more complex stampings with better accuracy and higher quality. Another benefit of improved press slide guides is a reduction in die maintenance and significant increases in die life. Historically, press slide guide systems have always improved as the demands for higher quality, increased part complexity and material toughness in metal stampings have increased. This trend continues today and the results can be seen in the following innovating guide systems. Figure #1 Copyright © 2005 AIDA-America Corporation. ALL RIGHTS RESERVED. 1

Open the catalog to page 1

Volume Eight Lube Free Zero-Clearance Roller Bearing Slide Guides A recent advancement in slide guiding for standard straight side presses has been the introduction of lube free, zero-clearance, roller bearings into the slide guide system. Historically, lube free roller slide guide technology and its’ advantages, have belonged exclusively to high-speed presses to meet a specific process requirement. High-speed presses are largely used to run very thin materials, a manufacturing process that requires the press to control small punch to die clearances. Lube free roller slide guides provide...

Open the catalog to page 2

Volume Eight This development of a lube-free slide guide different from high-speed standard slide guide technology - employs a proprietary roller bearing mount with the ability to swivel. This capability helps the roller maintain contact with the guide surface on the column during off-center load situations (see Figure #6). Increases in operations like in-die tapping and hardware insertion in the die have led to use of larger dies and more transfer die applications. With zero-clearance, the dry slide guide improves slide guiding and its “zero-clearance” characteristic provides immediate...

Open the catalog to page 3

Volume Eight Preloaded, Zero-Clearance Slide Guides With Oil Lubrication The latest development in precision slide guiding is the pre-loaded, zero clearance slide guide system with high-pressure oil lubrication. As with all other improvements in slide guiding, this system was developed to meet the increasing demands for more press accuracy. The result is a press that is more accurate than a die set because of this “ULTIMATE” slide guide. Slide tipping caused by high off-center die loads, slide shimmy caused by shock at the point of contact between the punch and material and snap-through at...

Open the catalog to page 4All Aida S.r.l. catalogs and technical brochures

-

dsf-c1-n1-n2-specs

6 Pages

-

NC Specs

2 Pages

-

DSF-C1-A

1 Pages

-

CHI

2 Pages

-

AIDA - Blanking line

9 Pages

-

Total transfer knowledge

3 Pages

-

Transfer press

2 Pages

-

Servo Mechanical Presses

1 Pages

Archived catalogs

-

Reverse tonnage

8 Pages

-

Transfer Technology Systems

4 Pages

-

Slide Suspension Designs

4 Pages

-

Press Balancing Systems

3 Pages

-

NC2 Gap Frame Presses

4 Pages

-

NC1 Gap Frame Presses

6 Pages

-

AIDA Srl COMPANY PROFILE

8 Pages

-

AIDA PRODUCT BROCHURE

6 Pages