Catalog excerpts

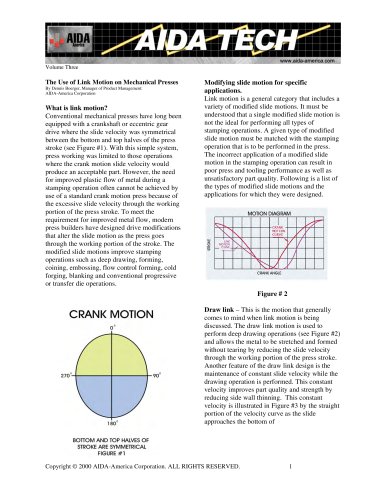

Volume Three The Use of Link Motion on Mechanical Presses By Dennis Boerger, Manager of Product Management: AIDA-America Corporation What is link motion? Conventional mechanical presses have long been equipped with a crankshaft or eccentric gear drive where the slide velocity was symmetrical between the bottom and top halves of the press stroke (see Figure #1). With this simple system, press working was limited to those operations where the crank motion slide velocity would produce an acceptable part. However, the need for improved plastic flow of metal during a stamping operation often cannot be achieved by use of a standard crank motion press because of the excessive slide velocity through the working portion of the press stroke. To meet the requirement for improved metal flow, modern press builders have designed drive modifications that alter the slide motion as the press goes through the working portion of the stroke. The modified slide motions improve stamping operations such as deep drawing, forming, coining, embossing, flow control forming, cold forging, blanking and conventional progressive or transfer die operations. Modifying slide motion for specific applications. Link motion is a general category that includes a variety of modified slide motions. It must be understood that a single modified slide motion is not the ideal for performing all types of stamping operations. A given type of modified slide motion must be matched with the stamping operation that is to be performed in the press. The incorrect application of a modified slide motion in the stamping operation can result in poor press and tooling performance as well as unsatisfactory part quality. Following is a list of the types of modified slide motions and the applications for which they were designed. Figure # 2 Draw link – This is the motion that generally comes to mind when link motion is being discussed. The draw link motion is used to perform deep drawing operations (see Figure #2) and allows the metal to be stretched and formed without tearing by reducing the slide velocity through the working portion of the press stroke. Another feature of the draw link design is the maintenance of constant slide velocity while the drawing operation is performed. This constant velocity improves part quality and strength by reducing side wall thinning. This constant velocity is illustrated in Figure #3 by the straight portion of the velocity curve as the slide approaches the bottom of Copyright © 2000 AIDA-America Corporation. ALL RIGHTS RESERVED. 1

Open the catalog to page 1

Volume Three Figure # 3 the press stroke. What must be understood is that the draw link motion is not good for blanking, coining, flow control forming or progressive die operations because of the small amount of time that the slide is near or bottom of the stroke. Progressive die link - As the name indicates, this modified slide motion is designed to enhance the performance of progressive die operations. Drag link or slider link are also terms that might be applied to this motion. The progressive die link is used to reduce the slide velocity through the working portion of the press stroke...

Open the catalog to page 2

Volume Three Figure # 7 Knuckle joint – Although the knuckle joint motion is not a link motion, it is a modified slide motion. This drive design is illustrated in Figure #7 and is used in presses where a very high degree of metal flow is required to produce the finished part. The knuckle joint design provides infinite pressure at the bottom of the press stroke and actually produces a dwell there. Knuckle joint drives are primarily used in heavy coining or cold forging operations for net shape or near net shape parts (see Figure #8) where secondary machining is eliminated. Figure # 6 In...

Open the catalog to page 3

Volume Three Figure # 9 Figure # 10 Feeds or transfers applied to link motion presses Using feeds or transfers on modified slide motion presses requires an understanding of the reduced time available in the upper portion of the slide stroke. Traditionally feed timing has been based on degrees of crankshaft rotation, however, because the slide velocity on link motion presses is increased through the upper portion of the press stroke, there is less time available to complete the feed cycle. Figure #9 is a timing chart for a standard crank motion press operating at 60 strokes per minute. With...

Open the catalog to page 4

Volume Three This increased acceleration may require that the press speed be reduced. However, this is not the case with servo driven feed systems because there is no mechanical tie to the press crankshaft. Does link motion improve die life? The answer to this question is a resounding “yes”. By modifying the slide motion and slowing it down through the working portion of the stroke, the high shock and vibration levels normally experienced in crank motion presses are significantly reduced. The shock and highest vibration levels occur while the punch is engaged with the material and lower die...

Open the catalog to page 5

Volume Three Are there other benefits achieved by using link motion? Although increased die life and improved part quality are prominent benefits achieved through the use of link motion press drives there are many other areas that are improved by this technology. Noise levels are reduced by 50% or more, which improves the environment for operators. The reduced shock and vibration lowers press maintenance costs and nearly eliminates nuisance failures: related guards shaking loose, wiring in press controls coming loose at the terminal points, fatigue cracks developing in sheet metal...

Open the catalog to page 6All Aida S.r.l. catalogs and technical brochures

-

dsf-c1-n1-n2-specs

6 Pages

-

NC Specs

2 Pages

-

DSF-C1-A

1 Pages

-

CHI

2 Pages

-

AIDA - Blanking line

9 Pages

-

Total transfer knowledge

3 Pages

-

Transfer press

2 Pages

-

Servo Mechanical Presses

1 Pages

Archived catalogs

-

Reverse tonnage

8 Pages

-

Slide guide systems

4 Pages

-

Transfer Technology Systems

4 Pages

-

Slide Suspension Designs

4 Pages

-

Press Balancing Systems

3 Pages

-

NC2 Gap Frame Presses

4 Pages

-

NC1 Gap Frame Presses

6 Pages

-

AIDA Srl COMPANY PROFILE

8 Pages

-

AIDA PRODUCT BROCHURE

6 Pages