Website:

AEROTECNICA COLTRI S.p.A.

Website:

AEROTECNICA COLTRI S.p.A.

Group: COLTRI

Catalog excerpts

Technical Data Sheet BOOSTER LINE ACE III ACE III ZERO LOSS ELECTRIC

Open the catalog to page 1

Technical Data Sheet Simplicity at the services of your company

Open the catalog to page 2

Technical Data Sheet Technical data Type of gas Intake pressure Nominal pressure Working pressure Permissible ambient temperature range Permissible altitude Soundproof cabinet with sound absorbing Operating voltage, standard Other operating voltage Steel - Colour Blue RAL 5002 Powder coating painting - Scratch proof Compressor Flow rate Purification System 2 Hyperfilter with activated carbon 1.960 m3/h 1 Standard model. Dimensions and weight may vary depending on accessories. Electric motor Power Three-phase electric Operating voltage/frequency Different voltage / frequency available on...

Open the catalog to page 3

Technical Data Sheet

Open the catalog to page 4

Technical Data Sheet 1st stage pressure gauge Control pannel Condensate discharge valves Stop pushbutton Safety valve Condensate discharge pushbutton Maintenance valve Oil level warning light Purifier filter Direction of rotation indicator light Hour counter Cabinet interior / cooling air temperature Pumping unit Emergency pushbutton Automatic shutdown pressure switch Pressure switch 3rd stage pressure gauge 1st stage gas recovery (only on Zero Loss version) 2nd stage pressure gauge

Open the catalog to page 5

Technical Data Sheet Forced lubrification with low pressure gear pump

Open the catalog to page 6

Technical Data Sheet Safety valves after each stage of compression Pipes, fitting and nuts in stainless steel AISI 316 Condensate separator after the medium pressure stage and final high pressure stage Synthetic Oil Coltri ST 755 with special formulation for HP compressors Discover more on Coltri Oil ST 755

Open the catalog to page 7

Technical Data Sheet Die-cast aluminium cylinders with barrel coating in nicasil Forged aluminum connecting rods Forged steel crankshaft Stainless steel second and third stage valves

Open the catalog to page 8

Technical Data Sheet Third stage in tempered steel with 5 piston rings in special cast iron Roller Bearings for intensive work load Second and third stage with pushing pistons to eliminate lateral forces on the pistons First stage for gas recovery (only for Zero Loss version)

Open the catalog to page 9

Technical Data Sheet Technical data pumping unit MCH 23 ACE I 4 KW Intake pressure Flow rate Speed (RPM) Number of stages 2 + 1 service (Zero Loss) 2 + 1 service (Zero Loss) Cylinder bore 2nd stage Cylinder bore 3rd stage Direction of rotation from flywheel side Counter clockwise (left) Drive type V-belt A type 1,8 liters

Open the catalog to page 10

Technical Data Sheet Standard equipment Purification system Hyperfilter for nitrogen DOUBLE HYPERFILTER regenerable or disposable cartridge Hyperfilter body Cartridge spring Hyperfilter cartridge Stainless hook Felt disc Purification system Operating pressure (Standard) Filtered gas volume (nitrogen) When using a filter cartridge of the type shown in the figure.

Open the catalog to page 11

Technical Data Sheet Separator system • Interstage separator in forged and anodized aluminum. • Final separator for removal of oil/water condensate. • Final safety valve, mounted on the separator housing. • Pressure maintenance valve / non-return valve. • Automatic condensate drain. * Measured at our facility using ASCO HORA 160 ANALYZER. 1 The level of CO2 in the intake air must not exceed the maximum level of CO2 as per EN 12021:2014 2 Reported values exceed ISO 8573-1 standards.

Open the catalog to page 12

Technical Data Sheet Filling connection 2 Filling connection to choose from: DRV DIN 232 bar and DRV DIN 300 bar. Filling device Technical Specifications Filling valve with integrated ventilation, with connection for G 5/8" cylinders to EN 144-2 and 477 PN232 Filling valve with integrated ventilation, with cylinder connector G 5/8” according to EN 144-2 and 477 PN300 Filling hose 1200 mm stainless steel fittings - max working pressure 420 bar

Open the catalog to page 13

Technical Data Sheet Electronic pressure switch The instrument allows to visualize the pressure expressed in bar, psi or MPa. Through the programming buttons it allows to set the intervention pressure of the relay contact (SPDT) and hysteresis. The settings are protected by passwords at 3 levels: manufacturer, customer and end user. The instrument also has the function of hours counter and no. of cycles of separator intervention, ensuring a general improvement of the operation of the recharge station over time and the longevity of its filters.

Open the catalog to page 14

Technical Data Sheet Interstage pressure gauges The function of the interstage pressure gauges is to show the operating pressure of the individual compression levels. This information is indispensable because it allows to quickly recognize a possible error by checking the tightness of the respective level valves (inlet and outlet). The interstage pressure gauges are mounted on the control panel of the compressor. 1st stage pressure gauge 2nd stage pressure gauge 3rd stage pressure gauge

Open the catalog to page 15

Technical Data Sheet Compressor control and automatic condensate drain system • ON/OFF switch with motor protection switch. • Optional: autostart at 60 bar hysteresis. • Transformer. • Pressure switch stops compressor at final pressure. • Drainage of all separators between the individual stages and also of the final separator during compressor operation (standard drain interval every 15 minutes for a period of 6 seconds). • Timer for automatic condensate drainage device. • Integrated vacuum start-up (automatic drain when the unit is switched off). • Condensate collection tank 5 liters, with...

Open the catalog to page 16

Technical Data Sheet Soundproof frame Polyether-based expanded polyurethane impregnated with halogen and CFC-free flame retardant substances. Soundproofing useful in any environment that requires a strong reduction of high frequencies. Certifications Color Thermal conductivity Temperature resistance Tensile hardness

Open the catalog to page 17

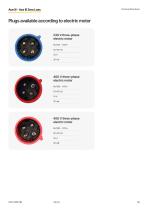

Technical Data Sheet Plugs available according to electric motor 230 V three-phase electric motor 9h/200 - 250V~ 50÷60 Hz 32 A 3P+ 400 V three-phase electric motor 6h/380 - 415V~ 50÷60 Hz 16 A 3P+ 400 V three-phase electric motor 6h/380 - 415V~ 50÷60 Hz 32 A 3P+

Open the catalog to page 18All AEROTECNICA COLTRI S.p.A. catalogs and technical brochures

-

TDS ACE VII ZERO LOSS

20 Pages

-

TDS ACE VI ZERO LOSS

20 Pages

-

TDS ACE V ZERO LOSS

20 Pages

-

2024 FIRE CATALOGUE - EN

28 Pages

-

2024 COMPRESSORS CATALOGUE

72 Pages

-

2024 CNG CATALOGUE

24 Pages

-

CATALOGUE COMPRESSORS 2023

108 Pages

-

CNG EVO

24 Pages

-

Filling stations

72 Pages

-

Portables compressors

28 Pages