Website:

ADVANTECH

Website:

ADVANTECH

Group: advantech

Catalog excerpts

Food & Beverage Processing Solutions Using Information and Communications Technology to build smart factories and traceable products Computer-assisted manufacturing system to streamline the food & beverage manufacturing process and establish a track and trace system from logistics management to production control Enabling an Intelligent Planet

Open the catalog to page 1

Intelligent Food & Beverage Manufacturing Overview ICT (Information and Communications Technology) realizes smart factories and synchronize sales and production In the new era of globalization, food and beverage producers operate manufacturing facilities located in different countries with a global supply chain. Therefore, building up a standardized and scalable production system is imperative for today’s corporate competitiveness. Smart factories are an industrial trend that use networking and intelligent technologies to integrate all the process, from sourcing and manufacturing to...

Open the catalog to page 2

Filling & Sealing Food/beverage is packed into a container and sealed in an aseptic process. Dosing & Mixing Ingredients are fed into mixing tanks for production. Business Information Center Management Platform • Device networking • Real time remote monitoring and control • Data collection, analyses and graphic presentation • Interfacing and Integration of manufacturing process

Open the catalog to page 3

Facts & Trends in the Food & Beverage Processing Industry j[The difficulty in realizing complete tracing records A complete food record tracing back to the very beginning of its ingredient supply, through manufacturing procedures, to logistics, transportation and finally to the retail site is de facto difficult. There are many links or interfaces of systems, many receipts and paperwork involved. A loophole or break could happen in any stage and affect data authenticity, making real time monitoring and preventive actions difficult. Shipping lot number Purchase orders from (he ERP...

Open the catalog to page 4

To fulfill complete and correct track and trace food records, smart technologies and new management tools are available. In the smart food factory, Patrol Inspection System is used in connection with the company’s Enterprise Resource Planning (ERP) system and Manufacturing Execution System (MES) to allow operators at each processing stage to report production status, equipment status, material usage and quality control. Operators usually use intelligent tools such as barcode readers or industrial tablets to enter data, and all devices in the factory are connected in a network. These are...

Open the catalog to page 5

Intelligent Food & Beverage Processing Solution Intelligent food & beverage processing solution based upon advanced ICT technologies, which is a seamless combination of shop floor data collection-including weighing and mixing , patrol inspection and equipment integration-- and higher level MES modules including WIP control, SPC, equipment management, and alarm management, expected to fulfill the manufacturer’s Computer-Integrated Manufacturing (CIM) objectives. Application Systems jap - * . | WebAcc ss ll Shop Floor

Open the catalog to page 6

Work In Process (WIP) module is the core module of Manufacturing Execution Systems (MES), which provides diverse functions and intuitive interface to allow users to receive information such as production records, quality reports, material usage and an equipment status, so that the users can perform real time control and management tasks over the shop floor to prevent processing errors. Basic Information Settings • Provides equipment management, production/process control, alerts management, label management, system management, etc. Production Management • Provides information of production...

Open the catalog to page 7

Alarm Management (ALM) Module Aims to meet shop floor management requirements, the alarm management system sets frequency for alarm issuing, message-forwarding vehicles and receivers to create an effective alarm system. The ALM module is an open platform able to integrate various information systems in the company and instantly forward alarm messages on equipment abnormalities to personnel in charge to allow for fastest handling and reduce loss. Equipment Management System (EMS) Module Equipment Management System (EMS) is a preventive maintenance platform that integrates maintenance and...

Open the catalog to page 8

Material Weighing and Mixing Module The module helps to standardize and computerize the operations in material storeroom, weighing area, and dosing and mixing area. All inbound materials are labeled with 1D/2D barcodes to facilitate measurement. The picking, request for and issuing of materials are implemented according to ERP procedures. In the weighing area, operators acquire materials according to production orders and recipes; inventory shortage and overage should be adjusted regularly. Patrol Inspection Module This module allowing operators to enter data with a handheld touch panel...

Open the catalog to page 9

The equipment can be integrated in a network by either using Advantech ’s monitoring control software WebAccess to connect with shop floor PLCs to acquire equipment data; or use ADAM or other data loggers to connect with modified devices to acquire analog data or use T50 networking hub to acquire digital data. This helps to realize real time consecutive monitoring control instead of the traditional scattering checkpoints. The data acquired automatically can be used to compare with manual records to determine if there is an abnormality. The connection of devices is shown below: Enterprise...

Open the catalog to page 10

Case Studies MES for Food & Beverage Project Introduction ■ Taiwan’s biggest food and beverage manufacturer initiated a MES to establish more efficient and accountable tracking records for their products so that they can quickly identify problematic ingredients and responsible suppliers. System Requirements b Five units of the Advantech industrial panel PWS-770 with WebAccess 7.1 are deployed in the field to collect real time production data at major control points, including ingredient measurement and proportioning, sterilization, filling and packaging. Some devices and meters are...

Open the catalog to page 11All ADVANTECH catalogs and technical brochures

-

PAC-6009

2 Pages

-

PAC-4010

2 Pages

-

SKY-7260S3P

2 Pages

-

TREK-120

3 Pages

-

TREK-303RH

2 Pages

-

TREK-570

4 Pages

-

TREK-572

2 Pages

-

TREK-734

2 Pages

-

TREK-530

2 Pages

-

TREK-130

1 Pages

-

DLT-V83

4 Pages

-

DLT-V72

2 Pages

-

DLT-V7210 K DLT-V7210 KD

3 Pages

-

DLT-V7212/V7215 P+

4 Pages

-

DLT-V4108

2 Pages

-

DLT-SA6100

1 Pages

-

TREK-ANT

3 Pages

-

Application-Ready Platforms

1 Pages

-

EKI-7708G-4FP EKI-7708G-4FPI

2 Pages

-

EKI-5525/I EKI-5528/I

2 Pages

-

EKI-7708E-4FP EKI-7708E-4FPI

2 Pages

-

EKI-7428G-4CI EKI-7428G-4CPI

2 Pages

-

EKI-9728G-4X8CI

2 Pages

-

EKI-1528I-DR EKI-1528CI-DR

2 Pages

-

EKI-1242PNMS EKI-1242IPNMS

2 Pages

-

EKI-1242EIMS EKI-1242IEIMS

2 Pages

-

BB-ABDN-ER-DP553

3 Pages

-

BB-WLNN-xx-DP551

2 Pages

-

BB-APMN-Q551

2 Pages

-

BB-ABDN-SE-DP553

3 Pages

-

EKI-6333AC-2G

2 Pages

-

EKI-9502G

2 Pages

-

EKI-6333AC-M12

2 Pages

-

BB-MESR901 BB-MESR902T

2 Pages

-

EKI-1228/CI/I-DR

2 Pages

-

EKI-1221I-MT EKI-1222I-SC

2 Pages

-

ADAM-6520

1 Pages

-

EKI-2712G-4FPI

2 Pages

-

EKI-2528I-M12

2 Pages

-

AMiS-50

2 Pages

-

POC-S199

2 Pages

-

POC-W152

2 Pages

-

POC-W212 IP54

2 Pages

-

POC-W213 IP54

4 Pages

-

PDC-W210

2 Pages

-

PDC-WP240

2 Pages

-

PAX-324

2 Pages

-

AIM-55

7 Pages

-

POC-W242

2 Pages

-

UTC-520

2 Pages

-

TREK-773

2 Pages

-

UTC-515

2 Pages

-

FPM-3191G

2 Pages

-

FPM-3171G

2 Pages

-

FPM-3151G

2 Pages

-

FPM-3121G

2 Pages

-

PPC-3150S

2 Pages

-

PPC-3060S

2 Pages

-

PPC-6191C

4 Pages

-

IPPC-5211WS

2 Pages

-

TPC-1551WP

2 Pages

-

TPC-1840WP

2 Pages

-

TPC-B500 TPC-B200 FPM-B700

2 Pages

-

ADAM-6260 ADAM-6266

1 Pages

-

ADAM-6217 ADAM-6224

1 Pages

-

ADAM-6117 ADAM-6124

1 Pages

-

ADAM-6060 ADAM-6066

1 Pages

-

ADAM-4017

1 Pages

-

ADAM-4115 ADAM-4015

1 Pages

-

MIC-1816

1 Pages

-

MIC-1810

1 Pages

-

AMAX-4817 AMAX-4820

1 Pages

-

USB-4620 USB-4622 USB-4630

1 Pages

-

PCIE-1680 PCI-1680U

1 Pages

-

USB-5855 USB-5856 USB-5862

1 Pages

-

USB-5830 USB-5850 USB-5860

1 Pages

-

USB-4716

1 Pages

-

USB-4711A

1 Pages

-

PCI-1752U PCI-1754 PCI-1756

1 Pages

-

PCI-1730U PCI-1733 PCI-1734

1 Pages

-

PCI-1714U PCI-1714UL

1 Pages

-

PCIE-1840 PCIE-1840L

1 Pages

-

PCIE-1802 PCIE-1802L

1 Pages

-

PCIE-1812

1 Pages

-

PCIE-1756 PCIE-1756H

1 Pages

-

PCIE-1730 PCIE-1730H

1 Pages

-

ECU-1152

1 Pages

-

ECU-1251

1 Pages

-

ADAM-3617-AE ADAM-3624-AE

1 Pages

-

ADAM-3651 ADAM-3656

1 Pages

-

ADAM-3600-C2G

2 Pages

-

ECU-4553

1 Pages

-

ECU-P1524PE

1 Pages

-

ECU-4784 XEON

1 Pages

-

APAX-5430 APAX-5435

1 Pages

-

APAX-5017H APAX-5028

1 Pages

-

APAX-5490 APAX-5090

1 Pages

-

APAX-5580CDS

2 Pages

-

APAX-5580

2 Pages

-

WISE-2211

2 Pages

-

WISE-2210

2 Pages

-

MIC-770 V2

3 Pages

-

UNO-238

3 Pages

-

UNO-247

2 Pages

-

UNO-148

5 Pages

-

UNO-137

2 Pages

-

AMAX-3110

2 Pages

-

PCI-1274

1 Pages

-

PCI-1203

1 Pages

-

PCIE-1203

1 Pages

-

PCI-1245 PCI-1265 PCI-1285

1 Pages

-

WOP-215K

2 Pages

-

WOP-212K

2 Pages

-

WOP-210K

2 Pages

-

WOP-208K

2 Pages

-

WOP-207K

2 Pages

-

WOP-204K

2 Pages

-

AMAX-658 AMAX-637

2 Pages

-

AMAX-5580

2 Pages

-

ECU-4574

1 Pages

-

ECU-579

2 Pages

-

PPC-MB-610

1 Pages

-

PPC-324W-PN4

2 Pages

-

PPC-3180SW

2 Pages

-

PPC-324W-P7

2 Pages

-

PPC-3151W

2 Pages

-

PCIE-1181 PCIE-1182

1 Pages

-

WISE-4220

2 Pages

-

UNO-1372G

2 Pages

-

EKI-1242ECMS EKI-1242IECMS

2 Pages

-

EKI-1242IPNMS

2 Pages

-

DLT-V6210

2 Pages

-

DLT-V7210 KD

3 Pages

-

DLT-V72 Series

4 Pages

-

LEO-WS10

2 Pages

-

LEO-W

1 Pages

-

AIM-68

10 Pages

-

PWS-872

8 Pages

-

AIM-65

9 Pages

-

UNO-2484G

4 Pages

-

UNO-2372G

3 Pages

-

UNO-2271G

3 Pages

-

AIMB-787

2 Pages

-

UNO-220-P4N2AE

2 Pages

-

UNO-3283G/3285G

3 Pages

-

UNO-1372G-J

2 Pages

-

UNO-1372GH

2 Pages

-

MIC-730AI

2 Pages

-

PCE-USB4

1 Pages

-

IPC-7130/7130L

2 Pages

-

IPC-5120/7120

2 Pages

-

PCE-4129

2 Pages

-

SKY-MXM-T1000

2 Pages

-

AIMB-707

2 Pages

-

ACP-2020G

2 Pages

-

AIIS-3410P

2 Pages

-

IPC-242

2 Pages

-

MIC-75G20

3 Pages

-

ITA-3650

2 Pages

-

PCE-7129

2 Pages

-

PCE-5129

2 Pages

-

PCE-5029

2 Pages

-

PCE-3029

2 Pages

-

AIMB-785

2 Pages

-

DVP-7011MHE

2 Pages

-

DVP-7635HE

2 Pages

-

DVP-7011UHE

2 Pages

-

SKY-6100

2 Pages

-

HPC-5000

2 Pages

-

MIC-7420

2 Pages

-

MIC-7700

2 Pages

-

AIIS-3400P

2 Pages

-

ACP-4340

2 Pages

-

IPC-631

2 Pages

-

ACP-2020

2 Pages

-

EKI-9508E-MPH

2 Pages

-

ITA-2231

2 Pages

-

ITA-1711

2 Pages

-

ITA-5231

3 Pages

-

ITA-5831

2 Pages

-

SQFlash Storage Modules

12 Pages

-

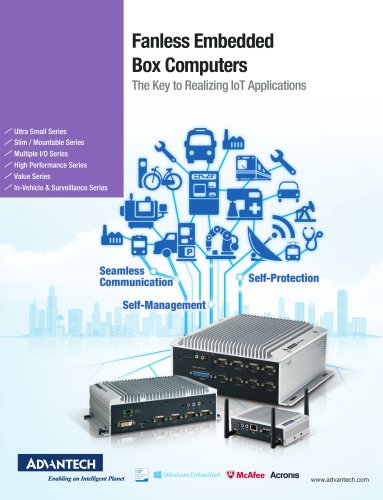

Fanless Embedded Box Computers

20 Pages

-

IoT Enabled ARM-Based Platforms

24 Pages

-

Computer on Modules

20 Pages

-

Industrial Display Systems

12 Pages

-

Industrial Motherboards

20 Pages

-

Embedded Single Board Computers

20 Pages

-

Modular IPCs

8 Pages

-

CompactPCI Solutions

16 Pages

-

Intelligent Video Systems

6 Pages

-

Data Acquisition Solutions

48 Pages

-

Predictive Maintenance Solutions

12 Pages

-

Advantech's Intelligent RTUs

16 Pages

-

Advantech's iDoor Technology

6 Pages

-

Power & Energy

6 Pages

-

IoT Wireless I/O Solutions

16 Pages

-

Control Cabinet PCs

6 Pages

-

Configurable Panel PCs

6 Pages

-

Modular Panel Platforms

6 Pages

-

2017 Advantech Panel PCs

6 Pages