Catalog excerpts

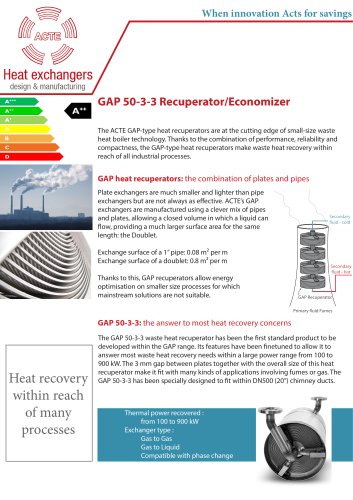

When innovation Acts for savings GAP 50-3-3 Recuperator/Economizer The ACTE GAP-type heat recuperators are at the cutting edge of small-size waste heat boiler technology. Thanks to the combination of performance, reliability and compactness, the GAP-type heat recuperators make waste heat recovery within reach of all industrial processes. GAP heat recuperators: the combination of plates and pipes Plate exchangers are much smaller and lighter than pipe exchangers but are not always as effective. ACTE’s GAP exchangers are manufactured using a clever mix of pipes and plates, allowing a closed volume in which a liquid can flow, providing a much larger surface area for the same length: the Doublet. Exchange surface of a 1” pipe: 0.08 m² per m Exchange surface of a doublet: 0.8 m² per m Thanks to this, GAP recuperators allow energy optimisation on smaller size processes for which mainstream solutions are not suitable. Fluid Secondaryinle fluid - cold Secondary fluid -Fluid outle hot ACTE GAP Economisor Recuperator Steam turbin Primary fluid Fumes GAP 50-3-3: the answer to most heat recovery concerns Heat recovery within reach of many processes The GAP 50-3-3 waste heat recuperator has been the first standard product to be developed within the GAP range. Its features have been finetuned to allow it to answer most waste heat recovery needs within a large power range from 100 to 900 kW. The 3 mm gap between plates together with the overall size of this heat recuperator make it fit with many kinds of applications involving fumes or gas. The GAP 50-3-3 has been specially designed to fit within DN500 (20”) chimney ducts. Thermal power recovered : from 100 to 900 kW Exchanger type : Gas to Gas Gas to Liquid Compatible with phase change

Open the catalog to page 1

Heat exchanger overview Mechanical features: Size and weight: Primary exchange surface: Duct connexion on the Primary side: DN500 Duct connexion on the Secondary side: DN50 Overall dimensions: Ø512 x 880 mm Weight: 90 kg Projected surface: 14.22 m² Gap between plates: 3 mm Technical features: To estimate your recuperator performances, please apply the following steps. First of all, please refer to the column corresponding to the chosen coolant (water or thermal oil). 1. Then apply the 5-stages procedure below: 1. Trace a vertical straight line through the two graphs corresponding to the...

Open the catalog to page 2

Water with 20% glycol Pressure Drop Fumes flow rate [Nm3/h] Water side pressure drop [Pa] -Pressure drop curve Fumes flow rate [Nm (h] Primary Side The flow rates given above have been calculated for a temperature difference of 20°C For any other temperature difference, the corresponding water flow rate is obtained using the formula below. The corresponding pressure drop is then determined following the initial = Water flow rate [m3/h] -Fumes @ SOtTC Pressure Drop Zone on Fumes Fumes flow rate [Nm3/h] Oil side pressure drop [Pa] -Pressure drop curve Fumes flow rate [Nm lti\ Primary Side The...

Open the catalog to page 3

When innovation Acts for savings Exchangers in parallel: If the drop in pressure on the fumes is too great, it is always possible to put two exchangers in parallel, which will have the effect of dividing the fume flow rate by two. The thermal power recovered then represents twice the power given by the graph. The liquid flow rate to be taken into account is also twice that given by the graph. For example: for a flow rate of 6000 Nm3 per hour at 450°C, the graph indicates a pressure drop of 2840 Pa, which may be too high according to your specification. By putting two exchangers in parallel...

Open the catalog to page 4All ACTE catalogs and technical brochures

-

HX GAP 30-3-2

4 Pages

-

COMPACT 55-7-0

4 Pages

-

COMPACT 70-7-0

4 Pages

-

COMPACT 95-9-0

4 Pages