Catalog excerpts

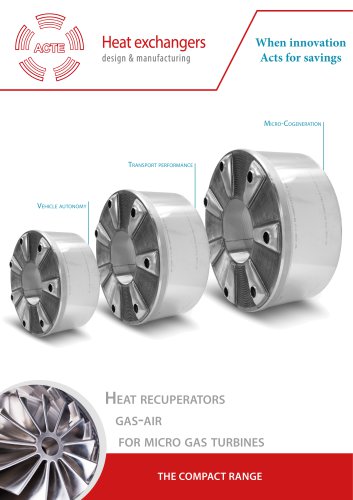

When innovation Acts for savings Technical datasheet The ACTE COMPACT-type heat recuperators are at the cutting edge of micro gas turbine recuperator technology. As these dedicated heat exchangers combine performance, lifetime extension and compactness, optimising micro gas turbine efficiency turns to be easier and sustainable. Thermal shocks and lifetime: the problem with flat plates The main challenge in designing heat recuperators for small gas turbines is ensuring a good lifetime while preventing significant performance losses due to thermal shocks in the transient i.e. when the gas turbine is starting or stopping. This issue can be attributed to the main component of every plate heat exchanger: the pressure retention system. In order to warrant the heat exchanger pressure resistance, heavy parts are frequently used to hold all the plates in contact. However, those heavy parts have a higher thermal inertia that generates mechanical conflicts with the honey comb primary surface structure. COMPACT heat recuperators: the benefits from the curvature Whereas the deformation direction of a flate plate can’t be determined in advance, the curvated one is predictable and constant. That is the reason the COMPACT range combines an annular shaped heat exchanger with radial collectors and a local pressure retention system. Thanks to this specific mix, ACTE heat recuperators provide an extended lifetime and high performances by reducing the difference in spare parts thermal inertia and managing the stress due to the thermal shocks involved. COMPACT 95-9-0: heat recovery for micro gas turbine from 180 kWe ACTE Recuperator (Compact HX) ACTE and the heat recovery breath Generator Combustion chamber Gas-to-air heat exchanger Designed for micro-gas turbines within a power range from 180 to 250 kWe

Open the catalog to page 1

Heat exchanger overview Mechanical features: Size and weight: Primary exchange surface: External diameter: 950 mm Internal diameter: 325 mm Connexion pipes: DN50 Projected surface: 107 m² Plates thickness: 3/10 mm Weight: 320 kg Technical features: To estimate your recuperator performances, please apply the 5-stages procedure below. 1. 1,5 kg/s 2. 87,7% 3. 5% 1. Trace a vertical straight line through the two graphs corresponding to the exhaust gas flow rate. 2. On the top graph, read the effectiveness from the black dashed curve and the left axis. 3. Depending on the pressure of the...

Open the catalog to page 2

Computation notes: In the here above charts, the curves are designed with an equivalent gas and air flow rate The total pressure drop are computed as follows: ^Ptot The recuperator thermal power and the outlet temperature can be computed from the charts by resolving the following equations: Q = E - Mar - Cpajr - CTi(liBas - T^) Q = Mar " Cpair - (T^air ~ Tm.air) Q = Mgas - cpgas - (Tin ga£ - Toutigas ) where: the flow rates are in [kg/s], the heat capacity in [J/(kg.K] and the temperature in [C] or [K]

Open the catalog to page 3

When innovation Acts for savings... Exchangers in parallel: If the drop in pressure on the fumes is too great, it is always possible to put two exchangers in parallel, which will have the effect of dividing the fume flow rate by two. The thermal power recovered then represents twice the power given by the graph. The liquid flow rate to be taken into account is also twice that given by the graph. A quick tip: using two smaller heat exchangers in parallel might be a smarter solution than developing a full tailored one. As a matter of fact this implies lower costs and a shorter production...

Open the catalog to page 4All ACTE catalogs and technical brochures

-

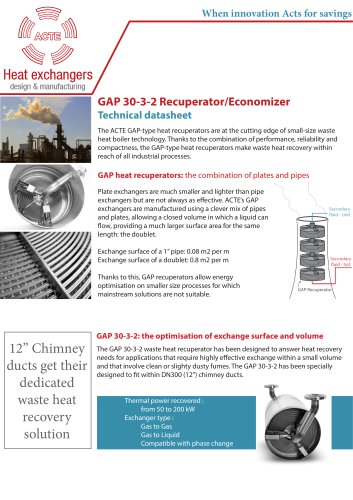

HX GAP 30-3-2

4 Pages

-

COMPACT 55-7-0

4 Pages

-

COMPACT 70-7-0

4 Pages