Website:

Accuway Machinery

Website:

Accuway Machinery

Catalog excerpts

Standard Accessor • Non- through hole 3-jaw hydraulic chuck • FANUC Oi-TD controller • Registered part program numbers: 400 • Part program memory size: 640 m • Heat exchanger for electric cabinet • Hydraulic power supply unit • Lubrication system • Three-color warning light • Chip conveyor & chip cart Optional Accessories hole 3-jaw hydraulic cylinder & chuck • Air cooler for electric cabinet • Auto door • Oil-coolant skimmer • ID turning tool holder • OD turning tool holder • Dual contact turning tool holders • 20 bar coolant through spindle • Renishaw tool setter * Design and specifications are subject to change without prior notice. No. 31, Fenggong Central Rd., Shengang Dist ..Taichung City 429, Taiwan E-mail: market@accuway.com.tw Website: www.accuway.com.tw

Open the catalog to page 1

Main Spindle Accuway vertical turning center UV series are designed and built to withstand the most demanding applications in various industries. UV series lathes offer highefficiency, high-accuracy, excellent rigidity and great stability. Large diameter main spindle bearing combining with wide range torque spindle motor offers highest rigidity while machining. Its strong structure further provides vibration absorption under the most demanding conditions to obtain excellent accuracy of versatile work- pieces. Structure Meehanite castings are internally reinforced with heavy ribs to resist...

Open the catalog to page 2

Second Spindle Au t o m a t i c To o l C h a n g e r ( AT C ) Hybrid 12-tool magazine ATC design of fers multiple machining capacity: turning, milling, drilling and rigid tapping operations while integrated with second spindle and live toolings. It eliminates secondary operations and increase productivity by reducing loading & unloading and fixture cost. Hardened, ground and balanced second-spindle is firmly encased in the robust saddle to withstand heavy duty machining. The power is transmitted to second-spindle through special transmission reduction generating enough speed and torque to...

Open the catalog to page 3

High Gear 37kW 30min Power Low Gear 30kW Continuous Power Low Gear 37kW Continuous Power Low Gear 30kW Continuous Torque High Gear 37kW 30min Torque High Gear 37kW Continuous Power High Gear 45kW 30min Power High Gear 30kW Continuous Power Low Gear 37kW Continuous Torque High Gear 45kW 30min Torque High Gear 30kW Continuous Torque Continuous Torque Continuous Power High Gear 37kW Continuous Torque High Gear 30kW Gear 30kW High Continuous Power Continuous Power Low Gear 30kW Gear 30kW Low Continuous Torque Continuous Torque High Gear 37kW Gear 37kW High 30min Torque 30min Torque High Gear...

Open the catalog to page 4

Facing tool holder Drill holder Face mill holder

Open the catalog to page 5

Chucking Capabilities Unit : mm MAIN SPINDLE Spindle speed range Spindle drive system Spindle motor type Spindle nose Spindle motor torque (Cont.) C-axis indexing resolution Table diameter SECOND SPINDLE Hydraulic chuck size Spindle bearing diameter Jaw FANUC Oi-TD Spindle taper size Max. spindle speed Spindle drive system Spindle bearing diameter Spindle motor type Spindle motor torque (Cont.) TRAVELS Max. X-axis travel Rapid traverse- X axis Rapid traverse- Z axis Machine Dimension Guideway type Boxway (Linear) X-axis servo motor Z-axis servo motor Front View Number of tool stations...

Open the catalog to page 6All Accuway Machinery catalogs and technical brochures

-

Total solution

22 Pages

-

UV series

6 Pages

-

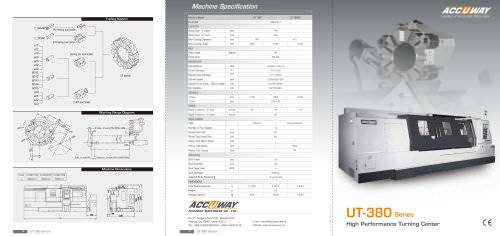

UT-380 Series

2 Pages

-

Muti-Tasking Turning Center

6 Pages

-

UM series

6 Pages

-

Vertical CNC Lathe

6 Pages

-

UT series

6 Pages

-

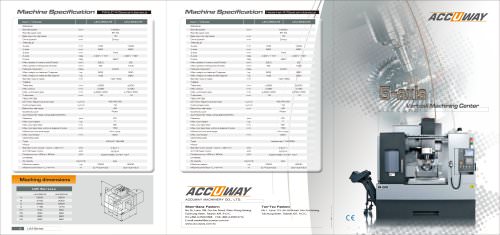

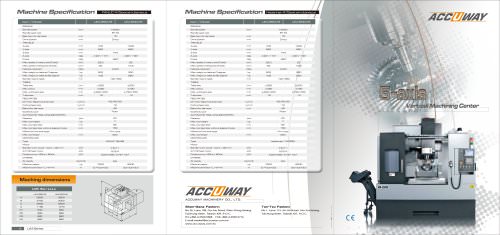

5 axis

2 Pages

-

Général

16 Pages

-

multi-tasking

6 Pages

-

UM40

2 Pages