Website:

Accuway Machinery

Website:

Accuway Machinery

Catalog excerpts

Leader of Accurate Machinery ACCUWAY MACHINERY CO., LTD. No. 31, Fenggong Central Rd., Shengang Dist., Taichung City 42942, Taiwan (R.O.C.) TEL: +886-4-2520 9588 FAX: +886-4-2520 9716 E-mail: market@accuway.com.tw Website: www.accuway.com.tw UT-400/UT-600 Series Super Heavy Duty Turning Center

Open the catalog to page 1

Rigid Basic Structure Rigid Basic Structure The 45 degree slant bed structural design consists of a one piece bed and box way casting with low center of gravity, large swing ciameter, superior rigidity for easy disposal of coolant and chips and longer tool life. Rigid Basic Structure Bed structure is internally reinforced with numerous heavy ribs to reduce deformation from shear or tensile stress. Each sliding surface is coated with Turcite-B to obtain long and stable operating life even under rigorous impact loading conditions. Fine grain wear resisting, shock-absorbing Meehanite cast iron...

Open the catalog to page 2

Powerful Main Spindle Design Power is delivered to the spindle through a two speed geared head allowing stable spindle speed changes as well as powerful torque output. Powerful Main Spindle Design Helical gears are incorporated in the gearbox to reduce noise, increase contact area, and reduce backlash for even high precision cutting. Headstock design, uses symmetrical heat-dissipating ribs, precision-bored and ground to reduce error from heat distortion, maintain circularity and concentricity, thereby ensuringlong-term cutting accuracy. Heavy duty servo controlled turret with 2-piece large...

Open the catalog to page 3

Strong Live Tooling for Long, Large Sized Workpieces UT-400 Machine dimensions Strong Live Tooling for Long, Large Size Workpieces UT-400/UT600 Tooling system & Machine dimensions Turret + C-axis index contr< ■ New design high rigid 12-station base mount tooling turret is capable of accepting rotary tools at any station, providing flexible machining through various machining operations in just one set-up. Each tool holder is securley tightened by 4 screws, allowing the turret to perform heavy-duty cutting, milling and drilling operations. Turret indexing is non-stop, bi-directional with a...

Open the catalog to page 4

32x32 facing tool holder facing tool holder 32x32 O.D facing tool holder ø20 ø25 ø32 Boring bar tool holder Boring bar tool holder ø40 ø40 U-drill tool holde U-drill tool holde ER 50 Axial driven tool holder Radial driven tool holder 745 Tailstock travel:1350 Tailstock travel:2050 Tailstock travel:2950 Tailstock travel:3950 Tailstock travel:1350 Tailstock travel:2050 Tailstock travel:2950 Tailstock travel:3950 Tool interference & Working range diagram Tool interference & Working range diagram Standard 12-Station Servo Turret Tailstock travel:1350 Tailstock travel:2050 Tailstock travel:2950...

Open the catalog to page 5

Machine Specification Machine Specification ^Specifications are subject to change without prior notice. ^Specifications are subject to change without prior notice. Machine Specification

Open the catalog to page 6All Accuway Machinery catalogs and technical brochures

-

Total solution

22 Pages

-

UV series

6 Pages

-

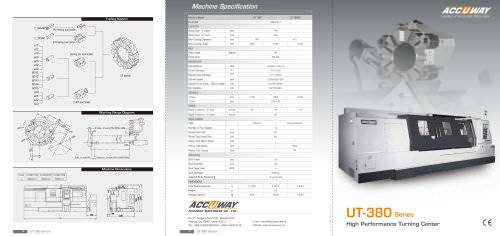

UT-380 Series

2 Pages

-

Muti-Tasking Turning Center

6 Pages

-

UM series

6 Pages

-

Vertical CNC Lathe

6 Pages

-

UT series

6 Pages

-

5 axis

2 Pages

-

Général

16 Pages

-

multi-tasking

6 Pages

-

UM40

2 Pages