Catalog excerpts

Quality of cast iron is vital to service life of machine tool. Accuway uses only casting made from Meehanite processed foundry with upgraded tensile strength and damping capacity. Meehanite castings have uniform soundness, corsistent physical properties and fine dense grain structure resulting in superior machine rigidity. They are heat treated to eliminate internal stresses resulting from solidification process to resist creep or fatigue under various operating conditions while maintaining machining accuracy over long periods of time. Based upon robust established and well proven machine...

Open the catalog to page 2

Digital Feeding System Multi-nozzle spindle coolant ring Accuway' s spindle uses P4-class precision angular bearings for strong axial resistance to counter cutting force. The grease-lubricated bearings are sealed and supplied with a lifetime lubricant to meet environmentally friendly and maintenance free requirements. Spindle nose is equipped with labyrinthine and air blow system to prevent penetration by chips or liquid. The spindle cartridge and machine headstock casting are chilled by re-circulating oil through the spindle nose to maintain consistent positioning accuracy over a wide...

Open the catalog to page 3

Tool magazine has capacity of 24 tools, fitted with quick and accurate autcmatic tool changing mechanism. Tool change requires only two to three seconds, saving cutting time and augment work PLC program design can manage a tool change for large-diameter cutting tool inside the tool magazine. Fully enclosed metal cover prevents chip penetration, keeps the tool holder, and spindle nose taper precision. Integrated interface, equipped with 4th and 5th axes for simultaneous complex machining, reduces errors during jig change as well as processing time. Operating Environment Movable control panel...

Open the catalog to page 4

& Quality Inspection The Best choice for high-precision,high-efficiency mold and die machining. By using a precision test bar fixed to the spindle and table, the machine is then put through a series of circular moves in the X/Y plane, and 1/2 circle moves in the X/Z and Y/Z planes. Any deviations in squareness or length show up as distorted circles providing an easy way for tuning the best servo control parameters to guarantee that the machine is accurate and properly aligned. Laser calibration After assembly, all machines are inspected using state of the art laser interferometer by...

Open the catalog to page 5

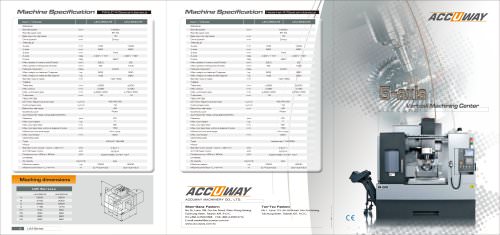

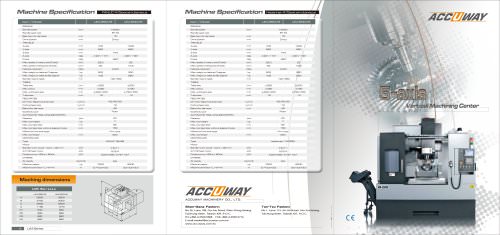

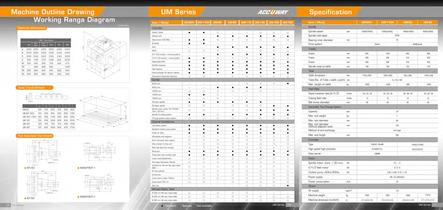

Working Ranga Diagram Machine dimensions

Open the catalog to page 6All Accuway Machinery catalogs and technical brochures

-

Total solution

22 Pages

-

UV series

6 Pages

-

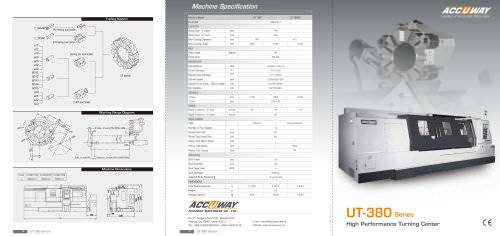

UT-380 Series

2 Pages

-

Muti-Tasking Turning Center

6 Pages

-

Vertical CNC Lathe

6 Pages

-

UT series

6 Pages

-

5 axis

2 Pages

-

Général

16 Pages

-

multi-tasking

6 Pages

-

UM40

2 Pages