Website:

ACCURATE BUSHING

Website:

ACCURATE BUSHING

Catalog excerpts

Smith Bearing > has a fully-integratedmanufacturing facility capable of producing high-precision needle roller bearings for both theAerospace and Industrial market. Our computerized(CNC) grinding and precision machining centers,considered to be the most advanced in the industryare capable of manufacturing a wide range ofproducts to exacting tolerances in order to meetthe needs of our customers. Our advanced metallurgical department routinely verifies and tests all raw materials, plating and heat-treatingprocesses used in the manufacturing of ourproducts. This careful analysis and scrutiny in each phase of our procedure assures properconformance to all Aerospace requirements andguarantees that only materials meeting our rigidstandards are used in Smith Bearing > ή products. > Extensive experience in our engineering departmentallows Smith Bearing > to work closely with end-users and OEMS (original equipment manufactures)in order to offer the best solution for their bearingrequirements. Smith Bearing > ή engineers haveextensive knowledge of available metallurgies so that they may offer customers their experience todetermine the best suitable material for a specialdesign and application. Smith manufactures bearings in a wide range of materials including high-carbon alloy steels, stainless steels, tool steels,and other exotic alloys. > Smith Bearing > has the ability to manufacture avariety of custom bearing assemblies. Typically this entails the precision machining of a bearinghousing and the assembly of needle or ball bearingsinto the housing. By controlling the entire design and manufacturing process of a custom order, Smith Bearing > ή guarantees the quality, perfor-mance, and delivery of an assembly. Smith Bearing > performs all aspects of such projects from design to finish including the machining process, applications of special coatings and plating, assembling andtesting of the final product. > Smith Bearing > ή has received both ISO 9001 and AS 9100 quality registrations in recognition ofour continued commitment to world-class qualitycontrol systems. Our quality system is recognized by General Electric, Lockheed, Boeing AircraftCorporation, British Aerospace, as well as many other military and aerospace companies. OurMilitary bearings meet the requirements of Mil-B-3990 ( SAE AS 39901 ). This level of qualitycertifications and approvals assures our customers unequaled dependability of our products. > www. smithbearing .com tel. 800.932.0076 ? fax. 908.789.9429

Open the catalog to page 1

SMITH Cam Followers are anti-friction needleroller bearings developed for use in cam or track roller applications. They were specificallydesigned and built to handle intermittentshock and heavy loads. Full compliment (non-caged) needle bearings maximize the radial load carrying capability while the soft innercore of the stud gives these cam followers theability to absorb extreme shock loads withoutfracturing.In addition to standard models, specialbearings are manufactured to customer specification for unique applications. It is often found that the use of special bearings reduces machine...

Open the catalog to page 2

ECCENTRIC CAM FOLLOWERS > Eccentric Sleeves Allow for Radial Location Adjustment of Cam Followers Add Suffix ֓E Cam Followers with a Press Fit EccentricSleeve > provide correct alignment andadjustment without costly preparation ofclose tolerance mounting holes and members. They eliminate problems ofclearances, preloading and wearcompensation and assure load sharing inmultiple cam follower applications. The hex-drive socket allows positive torque forlocking and adjustment. A lock nut will normally provide adequate clamping tohold bearing and eccentric sleeve in theirproper position. When...

Open the catalog to page 3

GreaseFitting Fig. 1 shows the re-lubrication path through the thr eaded-end ofthe stud (white area). The head-end is properly closed off using one of the two the plugs provided with each cam follower. Due to diameter constraints of the stud, smaller cam followers cannot be re-lubricated though the threaded-end. Plug Cam Followers and Cam Yoke Rollers arepacked at the factory with a petroleum-base,lithium grease with extreme pressure andcorrosive resistant additives. This lubricant issuitable for most bearing applications within a temperature range of -30F to 250ڋF. Re-lubrication in...

Open the catalog to page 4

Fig. 4 Mounting of a Stud TypeCam Follower > Fig. 5 Mounting of a Yoke TypeCam Follower > EccentricSleeve Fig. 6 Mounting of a Stud TypeCam Follower with Eccentric Sleeve > www. smithbearing .com tel. 800.932.0076 ? fax. 908.789.9429

Open the catalog to page 5

Properly selected bearings that havebeen suitably mounted and lubricated will operate for extended periods of timewith minimal wear until the fatigue life ofthe rolling elements is reached. Fatigue life of a bearing is reached when"spalling" or flaking of the contact surfaces (rolling element and raceway)occur from repeated stresses. Once the fatigue life of the rolling element or raceway is reached, wear and ultimatefailure of the bearing will occur very rapidly. The purpose is to select theproper type and size of bearing for the intended application in order to optimize performance and...

Open the catalog to page 6

Cylindrical Roller Diameter D Ӕ > TOLERANCESIZE Over IncludingMaximumMinimum 6 mm18 mm 0-0.008 mm18 mm30 mm0-0.009 mm 30 mm50 mm0-0.010 mm 50 mm80 mm0-0.013 mm 80 mm120 mm0-0.015 mm Crowned Roller Diameter D Ӕ > TOLERANCESIZE Over IncludingMaximumMinimum 6 mm120 mm0-0.050 mm Stud Diameter d Ӕ > TOLERANCESIZE Over IncludingMaximumMinimum 2 mm6 mm 0-0.012 mm6 mm10 mm0-0.015 mm10 mm18 mm0-0.018 mm 18 mm30 mm0-0.021 mm Bore Diameter d Ӕ for Yoke Rollers > TOLERANCESIZE Over IncludingMaximumMinimum 2 mm17 mm 0-0.008 mm17 mm30 mm0-0.010 mm 30 mm50 mm0-0.012 mm 50 mm80 mm0-0.015 mm 80 mm120...

Open the catalog to page 10All ACCURATE BUSHING catalogs and technical brochures

-

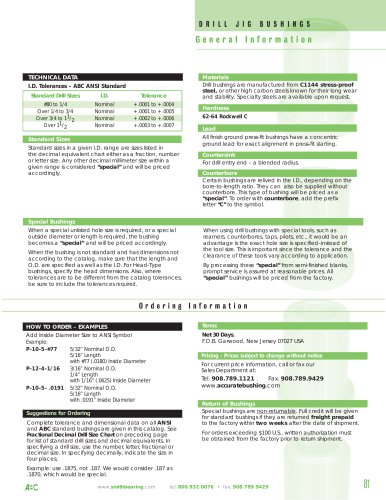

DRILL JIG BUSHINGS

1 Pages

-

Aerospace Bearings

2 Pages

-

Smith-Trax

1 Pages

-

ENGINEERING CAPABILITIES

10 Pages

-

Catalog 2014

116 Pages

-

SMITH BEARING ® Product Catalog

115 Pages

Archived catalogs

-

Drill Jig Intro

1 Pages

-

Aerospace Intro

2 Pages

-

SMITH-TRAX Intro

1 Pages

-

Complete catalogue

115 Pages