Catalog excerpts

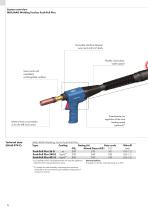

MIG/MAG Welding Torch Push-Pull Plus The "long-range torch" with the Plus … The welding torches of the Push-Pull Plus series – especially developed for aluminium welding requirements and the use of thin wires – makes problem-free and constant wire feed possible, even with longer cable assemblies. A powerful sturdy pull motor with potentiometer guarantees exact speed regulation. For an optimum wire feed without frictional loss, the contact pressure of the feeding rollers can be regulated precisely and easily directly on the handle. The ergonomic handle ensures optimum and low-fatigue handling. The screw-type torch necks can be replaced quickly. They are available as either straight or 45° angled versions. A special interface between the handle and the torch neck makes it possible to turn the necks by up to 360°. All torches, air and liquid cooled for capacities of up to 400 A, are based on the tried-and-trusted "MB" torch neck structure. The main areas of application for these welding torches include shipbuilding, container and tank manufacture etc., as well as construction of automobile and railway vehicles. Wherever exact and constant wire feeding is absolutely essential. The features: Constant and problem-free wire feeding thanks to a powerful pull motor Precise contact pressure regulation of the wire feeding rollers directly on the torch Optionally available with potentiometer for speed regulation Wearing parts are identical to those of the triedand-trusted MB torch series – minimised stocking Optimum torch cooling – long tool lives Sturdy design – long service life

Open the catalog to page 1

Screwable interface between swan neck and torch body Identical main consumables as for the MB-Torch series MIG/MAG Welding Torch Push-Pull Plus Type Cooling Rating (A) Duty cycle Wire-0CO2 Mixed Gases M21 (%) (mm)Push-Pull Plus 36 D air 300 270 60 0.8-1.2Push-Pull Plus 240 D liquid** 270 240 100 0.8-1.2 Push-Pull Plus 401 D liquid** 4003501000.8-1.6 *For complete torches with potentionmeter we need the additional General advice: indication of the required resistance value. At pulsed arc the duty cycles decrease up to 35%. **To protect the cable assembly components from excessive heat build...

Open the catalog to page 2

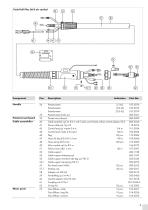

Optional with control lead plug Wire drive roll Wire inlet nipple with double groove Simplest presetting of the pressure by knurled screw Insulated pressure roll Order advice: The initial equipment of the complete torches Push-Pull Plus contains the following wear parts: Wear parts for Push-Pull Plus Description Contact tip holder (short) Gas diffuser Contact tip E-Cu; 0 1.2 Gas nozzle, conical Neckliner* PA liner Wire drive roll 0 1.2 / 1.2 Other wear parts can be ordered seperately. * Find Pos. 1 6 and 1 7 on the following pages.

Open the catalog to page 3

Push-Pull Plus 36 D air cooled Indication Part-No. Push-Pull Plus torch complete Torch neck Torch body, gear motor and equipment not ill. Push-Pull Plus 36 D; straight; 40 V motor; GZ-2, 8.00 m Push-Pull Plus 36 D; 45° bent; 40 V motor; GZ-2, 8.00 m Push-Pull Plus 36 D; straight; 40 V motor; poti 10 kQ; GZ-2, 8.00 m Push-Pull Plus 36 D; 45° bent; 40 V motor; poti 10 kQ; GZ-2, 8.00 m 1 Torch neck Push-Pull Plus 36 D; straight 2 Torch neck Push-Pull Plus 36 D; 45° bent 3 Wear parts set gasket rings 5 pcs. 12 Gear motor 24 V DC incl. Pos. 19 (Wire-0 1.2 mm) and Pos. 20 Gear motor 40 V DC incl....

Open the catalog to page 4

Push-Pull Plus 36 D air cooled Indication Part-No. Printed circuit board Cable assemblies Wear parts Potentiometer Potentiometer Potentiometer Potentiometer knob cpI Printed circuit board Cable assembly cpl. for 8.0 m with 7-pole control leads without central adaptor GZ-2 Power cable cpl. Typ 35 Control lead cpl. 4-pole 0.4 m 0.4 m Wire conduit cpl. for 8.0 m Fabrics hose 28x1.5 mm 40 m Cable support Cable support fastening cpl. Cable support machine side big cpl. ND 31 Cable support spring big ND 31 Pan head screw M4x6 20 pcs. Adaptor nut M33x2 Powerfitting cpl. M14x1 Central adaptor GZ-2...

Open the catalog to page 5

Push-Pull Plus 36 D air cooled Indication Part-No. Wear parts 86 Contact tip holder M6; 28.0 mm (short) 10 pcs. 87 Contact tip holder M6; 32.0 mm (long) 10 pcs. 88 Contact tip holder M8; 28.0 mm (short) 10 pcs. 89 Contact tip holder M8; 34.0 mm (long) 10 pcs. 120 Guide spiral liner blank; 2.0/4.5; Wire-0 0.8-1.2; for 8.00 m Guide spiral liner insulated; 2.0/4.5; Wire-0 0.8-1.2; for 8.00 m 130 PTFE core liner 2.0/4.0; red; Wire-0 0.8-1.2; for 8.00 m

Open the catalog to page 6

Indication Part-No. Wear parts 130 PTFE carbon core liner 2.0/4.0; Wire-0 0.8-1.2; for 8.00 m Polyamid core liner 2.0/4.0; Wire-0 0.8-1.2; for 8.00 m 131 Nipple for core liner at 4.0 133 Guide tube for core liners up to 4.0 (200 mm) 200 Spanner

Open the catalog to page 7

Push-Pull Plus torch complete Torch neck Torch body, gear motor and equipment not ill. Push-Pull Plus 240 D; straight; 40 V motor; WZ-2, 8.00 m Push-Pull Plus 240 D; 45° bent; 40 V motor; WZ-2, 8.00 m Push-Pull Plus 240 D; straight; 40 V motor; poti 10 kQ; WZ-2, 8.00 m Push-Pull Plus 240 D; 45° bent; 40 V motor; poti 10 kQ; WZ-2, 8.00 m 1 Torch neck Push-Pull Plus 240 D; straight 2 Torch neck Push-Pull Plus 240 D; 45° bent 3 Wear parts set gasket rings 5 pcs. 12 Gear motor 24 V DC incl. Pos. 19 (Wire-0 1.2 mm) and Pos. 20 Gear motor 40 V DC incl. Pos. 19 (Wire-0 1.2 mm) and Pos. 20 16...

Open the catalog to page 8

Printed circuit board Cable assemblies and wear parts 39 Printed circuit board 40 Cable assembly cpl. for 8.00 m with 7-pole control leads without central adaptor WZ-2 41 Power cable cpl. (PVC) for 8.00 m 42 Wire conduit cpl. for 8.00 m 43 Control lead cpl. 4-pole 0.4 m 44 Control lead 7-pole 0.34 qmm 49 Hose 47 blue 0 5.5x1.5 49.1 Fastener cap blue 53 Cable support fastening cpl. 55 Plug nipple ND5 mm / 0 6.0 56 Cable support machine side big cpl. 56.1 Cable support spring big ND 31 57 Pan head screw M4x6

Open the catalog to page 9

Gas diffuser, silicon 80 Contact tip holder M6; 26.0 mm 90 Contact tip M6 E-Cu; 0 0.8 (8x28) Contact tip M6 E-Cu; 0 1.0 (8x28) Contact tip M6 E-Cu; 0 1.2 (8x28) Contact tip M6 CuCrZr; 0 0.8 (8x28) Contact tip M6 CuCrZr; 0 1.0 (8x28) Contact tip M6 CuCrZr; 0 1.2 (8x28) Contact tip M6 E-Cu; 0 0.8 for alu wire (8x28) Contact tip M6 CuCrZr silver plated; 0 0.8 (8x28) Contact tip M6 E-Cu; 0 1.0 for alu wire (8x28) Contact tip M6 E-Cu; 0 1.2 for alu wire (8x28) Contact tip M6 CuCrZr silver plated; 0 1.0 (8x28) Contact tip M6 CuCrZr silver plated; 0 1.2 (8x28) 100 Gas nozzle; cylindrical; NW 0...

Open the catalog to page 10All ABICOR BINZEL catalogs and technical brochures

-

TIG CATALOG 4.2

48 Pages

-

Operating instructions

40 Pages

-

ABIBLUE

2 Pages

-

AB Series

12 Pages

-

Plasma

24 Pages

-

MIG_MAG

60 Pages

-

Image brochure

24 Pages

-

WH Tandem W800

8 Pages

-

W600 Torch Series

6 Pages

-

EWR

8 Pages

-

ABIMIG® A T VARIO

9 Pages

-

ABIMIG® A T

12 Pages

-

ABIMIG® A T COMBI

16 Pages

-

ABITIG® GRIP 500 W

4 Pages

-

E3® Brochure

4 Pages

-

ABIPLAS® WELD

6 Pages

-

Pure Power ...

6 Pages

-

iCAT

6 Pages

-

MFS V2

8 Pages

-

RAB Plus

2 Pages

-

MB GRIP SC

2 Pages

-

TIG-Torch overview 1.0/V1

514 Pages

-

TIG-Spare Parts List

120 Pages

-

MIG/MAG-Spare Parts 2.0/V1

176 Pages

-

Accessories- Catalogue 2.0/V2

28 Pages

-

MIG/MAG- Catalogue 3.0/V1

44 Pages

-

gouging torch G3000 / G4000

4 Pages

-

ROBO product catalogue 3.0

116 Pages

-

TIG product catalogue 3.1 / V1

40 Pages