Conformal coating for an additional layer of protection Safeguarding your protection relay against harsh environments

2Pages

Catalog excerpts

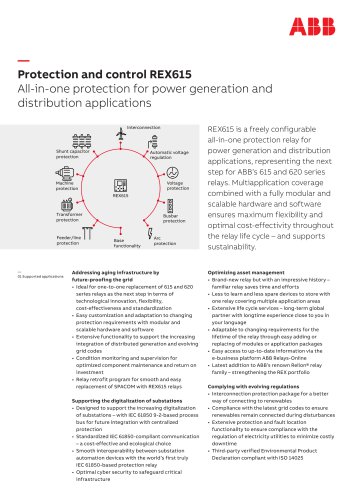

Conformal coating for an additional layer of protection Safeguarding your protection relay against harsh environments For outstanding performance also in the most extreme environments, ABB offers its Relion® 615, 620 and 640 protection relays with conformal coating as an option. This additional layer of protection increases the relay’s resistibility against harsh environmental conditions, and thereby the reliability of the entire power distribution system, with optimal asset management as a result. The chosen coating is recognized by Underwriters Laboratories (UL) and compliant with the US military specification MIL-I-46058C, IPC-CC-830 (Institute of Printed Circuits) and the RoHS (Restriction of Hazardous Substances) directive 2002/95/EC. Benefits • Additional layer of protection for the electronic circuits on PWBs • Maximized resistibility against high-humidity conditions, and corrosive and contaminant agents in the environment • Minimized costly production downtime and power outages in the distribution network through reliable performance of the relay • Optimal asset management and return on investment due to enhanced durability and reliability in harsh environments — Conformal coating - maximizing the resistibility 01 Industrial plants often represent challenging against moisture and c°rr°sive agents and harsh environments. Electronic components such as printed wired boards (PWBs) can be exposed to a variety of harsh conditions during the lifetime of the protection relay. Heavy moisture, chemicals and other corrosive agents such as H2S (hydrogen sulfide) gas commonly found in certain industries create a harsh environment that might negatively impact both the durability and reliability of the relay. Adding a conformal coating to the PWB not only protects the electronic circuits from the harsh environment, but thereby also enhances the reliability and extends the durability of the entire relay. Reliable operation throughout the relay's life cycle translates into less unplanned maintenance breaks and maximized uptime as well as maximum return on investment. Accredited coating for excellent performance ABB has chosen a single-component, high-solid, acrylated polyurethane coating for excellent resistance to moisture and chemicals. In addition to combating corrosion, the coating provides a highly durable protective shield against mechanical stress.

Open the catalog to page 1

01 The PWB is covered with a high-class coating, following ABB's strict coating procedures. 02 The Relion® 615, 620 and 640 protection relays can be conformal-coated for optimal resistance to harsh environmental conditions. Standardized testing for optimal reliability All ABB’s medium-voltage protection relays are extensively tested to meet or exceed the requirements of the latest industry standards. The following environmental tests are performed on both uncoated and coated relays: Decription Type test value Reference 16hat-40°C Damp heat 6 cycles (12 h + 12 h) at +25°C IEC 60068-2-30...

Open the catalog to page 2