Catalog excerpts

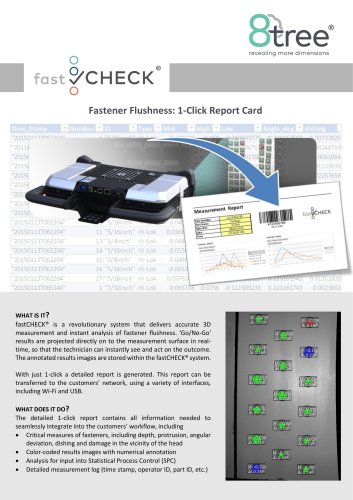

Step Inspection with real-time Visual Feedback How flush are those panels? We will show you instantly! WHAT IS IT? stepCHECK is a revolutionary 3D surface inspection system that delivers panel flushness analysis quickly and seamlessly. Zero Programming, Zero Post-Processing, Zero Surface Preparation HOW DOES IT WORK? stepCHECK delivers accurate 3D measurement and instant analysis of step height, parallelism, and flushness finish between adjacent surfaces. With a single click, stepCHECK measures the relative position between multiple neighboring surfaces. “Go/No-go” results are instantly visualized on the measured surface, using augmented reality. The Measurement Surface Becomes the Screen™ The specifically designed to solve fit/finish challenges in the manufacturing environment, stepCHECK boosts inspection efficiency by measuring numerous points along adjacent surfaces, in a single scan! It is a fully self-contained unit and completely tetherless – no external computer, no external monitor and no cumbersome power supply cables. stepCHECK is part of a family of truly portable, yet powerful measurement tools from 8tree. Brochure.docx / 02 2021 EN 8TR-BRO-021-011 stepCHECK Technical Data are subject to change without no

Open the catalog to page 1

Flushness, Parallelism, Line Profile, Flatness, and more! Performance Overview of stepCHECK Field of View (FoV) Flush (height) Gap (lateral) Flush (height) Gap (lateral) Acquisition Time Measurement Speed Battery Life Nominal Working Distance (still usable while charging) (with integrated CPU and battery) stepCHECK sets a new Industry Benchmark for 10x faster than current industry standard Lightweight, compact, battery-powered, integrated CPU Easy to handle on the production floor Real-time visual feedback and intuitive user interface Easily customized to different tolerance needs...

Open the catalog to page 2All 8tree’s catalogs and technical brochures

-

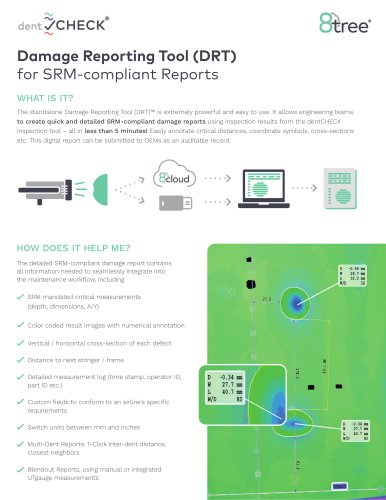

Damage Reporting Tool (DRT)

2 Pages