Catalog excerpts

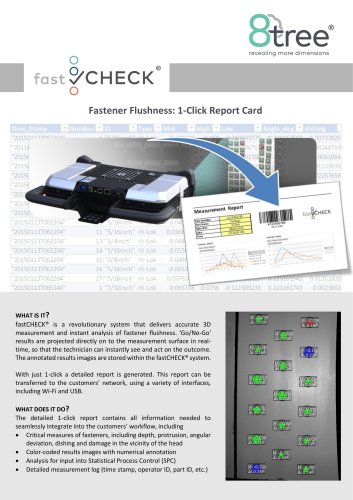

Fastener Inspection with Real-Time Visual Feedback High-Precision 3D Fastener Inspection was never so easy! WHAT IS IT? fastCHECK® is a revolutionary 3D surface inspection system that is amazingly easy to use – fast, simple and intuitive. It represents a ground-breaking approach to measuring fastener flushness – quickly, consistently and objectively. HOW DOES IT WORK? fastCHECK® delivers high-accuracy 3D measurement and analysis of fastener flushness and angle, at the push of a button. Realtime visualization of results is achieved by augmented reality (AR), which presents the measurement results directly on to the measurement surface. The measurement Surface Becomes your ScreenTM! Specifically tailored to the requirements of fastener and rivet inspection, fastCHECK® delivers easy-to-understand analysis of fastener flushness. Designed to be a fully self-contained unit, fastCHECK® is completely tetherless – no external computer, no external monitor and no cumbersome power-supply cables. fastCHECK® is the first in -aFastcheck Brochure.Docx / 03 yet powerful, 8TR-BRO-011-013 family of truly portable, 2019 EN measurement analysisare subject to change without notice Technical Data tools fr

Open the catalog to page 1

Optically measures and marks up to 30 Fasteners in 4 Seconds Performance Overview of fastCHECK® Field of View (FoV) Resolution Flushness Diameter Flushness Diameter Acquisition Time Rivet & Fastener Inspection Capability Measurement Speed Battery Life minimum 100 ms enables handheld operation Up to 30 fasteners at once Approx. 4 seconds up to 4.5 hours (still usable while charging) Nominal Working Distance Weight (without tripod) Dimensions 50 ± 5 cm / 20 ± 2” 4 kg / 8.8 lbs (with integrated CPU and battery) 35.4 x 30.0 x 9.0 cm / 13.9 x 11.8 x 3.6” fastCHECK® sets a new industry benchmark...

Open the catalog to page 2All 8tree’s catalogs and technical brochures

-

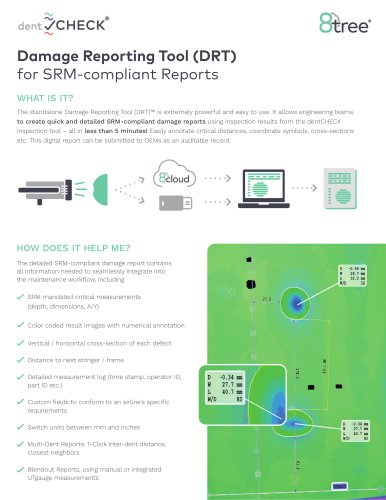

Damage Reporting Tool (DRT)

2 Pages