3NINE RIX - THE NEW SCREW ACTION OIL SKIMMER BASED ON SCREW TECHNOLOGY THAT ONLY SEPARATES OUT YOUR TRAMP OIL

2Pages

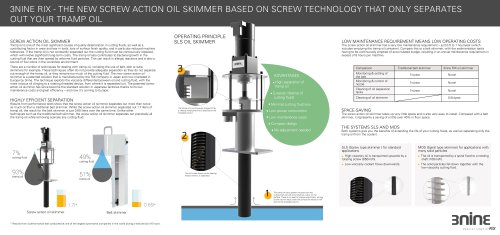

Catalog excerpts

3NINE RIX - THE NEW SCREW ACTION OIL SKIMMER BASED ON SCREW TECHNOLOGY THAT ONLY SEPARATES OUT YOUR TRAMP OIL SCREW ACTION OIL SKIMMER Tramp oil is one of the most significant causes of quality deterioration in cutting fluids, as well as a contributing factor in wear and tear in tools, loss of surface finish quality, and in particular reduced machine tolerances. If the tramp oil is not constantly separated out the cutting fluid must be continuously replaced, which will involve significant long-term costs. The tramp oil also contributes to bacterial growth in the cutting fluid that are then spread by airborne fluid particles. This can result in allergic reactions and is also a source of foul odors in the workshop environment. There are a number of techniques for dealing with tramp oil, including the use of belt, disk or tube skimmers for example. These techniques often do not provide adequate separation as they do not separate out enough of the tramp oil, or they remove too much of the cutting fluid. The new screw action oil skimmer is a patented solution that is manufactured by the RIX company in Japan and now marketed in Europe by 3nine. The technique exploits the viscosity differential between oil and cutting fluid, with the more viscous oil clinging to a rotating threaded device, from where it is separated out. The patented screw action oil skimmer has since become the standard solution in Japanese factories thanks to its low maintenance costs and great efficiency – and now it’s coming to Europe. OPERATING PRINCIPLE SLS OIL SKIMMER LOW MAINTENANCE REQUIREMENT MEANS LOW OPERATING COSTS The screw action oil skimmer has a very low maintenance requirement – just 0.5 to 1 hour/year (which includes emptying the tramp oil container). Compare this to a belt skimmer, with the sedimentation tanks having to be continuously emptied of accumulated sludge, resulting in an annual maintenance requirement in excess of 8 hours per machine. ADVANTAGES High separation of tramp oil Extends lifetime of cutting fluids HIGHLY EFFICIENT SEPARATION Results from performance tests show that the screw action oil skimmer separates out more than twice as much oil than a traditional belt skimmer. While the screw action oil skimmer separated out 1.7 liters of tramp oil, the result for the belt skimmer is just 0.65 liters over the same time. Unlike other techniques such as the traditional belt skimmer, the screw action oil skimmer separates out practically all the tramp oil while removing scarcely any cutting fluid. Low power consumtion Low maintenance costs No adjustment needed The oil is then drawn up the rotating thread where it is separated. * Results from a performance test conducted at one of the largest automotive companies in the world during a test period of 6 hours. The screw action oil skimmer takes up very little space and is also very easy to install. Compared with a belt skimmer, it represents a saving of a little over 40% in floor space. Both systems give you the benefits of extending the life of your cutting fluids, as well as separating only the tramp oil from the coolant. Low-viscosity coolant flows downwards. Screw action oil skimmer High-viscosity oil is transported upwards by a rotating screw (850ml/h). cutting fluid Cleaning of oil separation tanks SLS (Screw type skimmer ) for standard applications Monitoring & setting of the belt Monitoring & control of nozzle Minimal cutting fluid loss The tramp oil is continuously scraped off by a rotating metal plate that is attached to the threaded column. Compact design cutting fluid Traditional belt skimmer The tramp oil has a greater viscosity than the cutting fluid and will accumulate as a layer on the surface. There is no need for precise adjustment, as long as the column stays under the surface the tramp oil will stick to the threaded column. MOS (Spiral type skimmer) for applications with many solid particles The oil is transported by a spiral fixed to a rotating shaft (100ml/h). The solid particles fall down together with the low-viscosity cutting flu

Open the catalog to page 1

SPECIFICATIONS AND DIMENSIONS Spiral type: MOS- SCREW ACTION Dimension drawing SLS oil skimmer EXTENDS THE LIFE OF CUTTING FLUID AND MACHINERY Dimensions for installation Induction motor, 1-phase, 220V/230V with terminal box Motor drawing Induction motor, 3-phase, 380V/400V/415V with terminal box Motor drawing Capacity (ml/hr) * Note that the 150 mm models only are available in Japan. It is possible to order from Japan at demand. ** Depending on the amount of oil and its viscosity. Motor drawing Capacity (ml/hr) (All oil skimmers are delivered without a cable.) Flange dimension Motor:...

Open the catalog to page 2