カタログの抜粋

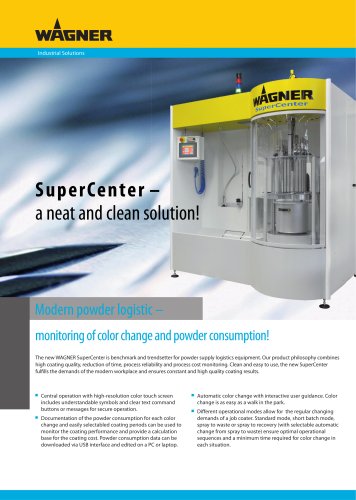

Industrial Solutions S uperCenter – a neat and clean solution! Modern powder logistic – monitoring of color change and powder consumption! The new WAGNER SuperCenter is benchmark and trendsetter for powder supply logistics equipment. Our product philosophy combines high coating quality, reduction of time, process reliability and process cost monitoring. Clean and easy to use, the new SuperCenter fulfills the demands of the modern workplace and ensures constant and high quality coating results. Central operation with high-resolution color touch screen includes understandable symbols and clear text command buttons or messages for secure operation. Documentation of the powder consumption for each color change and easily selectabled coating periods can be used to monitor the coating performance and provide a calculation base for the coating cost. Powder consumption data can be downloaded via USB interface and edited on a PC or laptop. Automatic color change with interactive user guidance. Color change is as easy as a walk in the park. Different operational modes allow for the regular changing demands of a job coater. Standard mode, short batch mode, spray to waste or spray to recovery (with selectable automatic change from spray to waste) ensure optimal operational sequences and a minimum time required for color change in each situation.

カタログの1ページ目を開く

The color change multi-talent! Automatic powder box changing – complete without down time! Superior finishing quality by PI-F1 or HiCoat-ED powder pumps Technical Data Dimensions Weight Hight Standard coating including fresh powder supply Short batch coating without fresh powder supply Manual operation Spray to waste and spray to recovery Automatic change from spray to waste to recovery with selectable delaytime Set-up mode Powder output measurement function Color change, automatic process with on-screen dialogue to the operater Connections Electrical Exhaust connection To final filter,...

カタログの2ページ目を開くWAGNERのすべてのカタログと技術パンフレット

-

Brochure PEM-X1 CG

4 ページ

-

Corona and Tribo Guns

10 ページ

-

Brochure Cobra

4 ページ

-

PXS Powder Centers

2 ページ

-

TOPFINISH DD10

2 ページ

-

FENCE & DECKING SPRAYER

36 ページ

-

C-Line

6 ページ

-

WOOD- & METALWORKING

12 ページ

-

Unica AME

4 ページ

-

BROSCHÜRE COBRA AME

8 ページ

-

DD10

2 ページ

-

Control Pro 350 R

144 ページ

-

Control Pro 350 M

144 ページ

-

Control Pro 250 M

140 ページ

-

W 990 FLEXiO

122 ページ

-

W 950 FLEXiO

130 ページ

-

FineCoat 9900

6 ページ

-

FineCoat 9900 PowerCart

52 ページ

-

Zip 52

68 ページ

-

FinishControl 5000

132 ページ

-

FinishControl 3500

132 ページ

-

Basic Booth Systems

2 ページ

-

SuperCube

4 ページ

-

Prima Cube

4 ページ

-

ID-Booth System LV

4 ページ

-

Profi Tech M

8 ページ

-

Profi Tech S

6 ページ

-

Prima Tech CCM

4 ページ

-

SuperFinish

5 ページ

-

Finish Control 5000

2 ページ

-

PROTEC GM

2 ページ

-

BO GM 4000AC AME WEB

8 ページ

-

SuperFinish SF 27

8 ページ

-

Finish 270

6 ページ

-

EPG_SL_5

2 ページ

-

TempSpray

6 ページ

-

PS 3.21 Spraypack

8 ページ

-

PrimaTechCCM

4 ページ

-

profitech S

6 ページ

-

SuperTech

4 ページ

-

ProfiTech

2 ページ

-

VertiCube

1 ページ

-

C4 HiCoat

4 ページ

-

Inline pump IP5000

2 ページ

-

DigiTech

2 ページ

-

Unica 4-270

4 ページ

-

TwinControl

8 ページ

-

SupraCoat

4 ページ

-

RoboCoat

2 ページ

-

IceBreaker®

8 ページ

-

GA 3000 AC

4 ページ

-

Evobell

4 ページ

-

Electrostatic guns

8 ページ

-

AirCoat guns

4 ページ

カタログアーカイブ

-

Cobra® 40-10

8 ページ

-

SuperCube_en

4 ページ

-

C4_brochure

4 ページ