ウェブサイト:

TSM Control Systems

ウェブサイト:

TSM Control Systems

カタログの抜粋

Continuous blending solutions with total reliability, precision and process control options ensuring material homogeneity and guaranteeing consistent product quality. Thats what you get from the TSM Sigmablend range. It provides continuous gravimetric and throughput control of up to eight components. The Sigmablend controls the blend percentages while also maintaining the extruder throughput at the desired level, i.e. kg/hr control. Haul off speed measurement can be added to ensure that the weight per length is controlled to the desired specification (yield control). This ensures that the product being produced is maintained at the desired thickness without operator intervention. This mode can be extended to weight per area control through entry, or automatic measurement of material width. > The TSM Sigmablend provides a "dosing" solution to gravimetric blending and extrusion control for up to 8 components. The primary component is gravity fed directly to the extruder throat and the secondary (side fed materials) maintain recipe ratio via auger feeds. Blending Option Throughput Sigmablend 400 400 kg (880 lbs) / hour Sigmablend 1000 1000 kg (2200 lbs) / hour Sigmablend 1800 1800 kg (3960 lbs) / hour > The Sigmablend 1000 No material separation or de-mixing Precise control of recipes Rapid achievement of Set-point Target Rugged Design Easily removable, easy clean, augers and hoppers Liquid Additive Control Option Offline mode selectable Clean Mode / Easy Recipe Change Comprehensive serial communications ports using industry standard Modbus / Profibus protocols Gravity fed main component allows recipe changes "On the Fly" and minimal waste Brushless motor option for maintenance free auger drives User friendly Remote Operator Interface Kg/hr / Weight Per Length Control Ethernet interface option, MODBUS TCP Full Manual Backup option Central OPC server software provides for remote monitoring and database of logged reports for inventory control Easy to service due to modular electronics Comprehensive printable reports on shift order, reel and material usage information >

カタログの1ページ目を開く

An easy-to-service control module, as shown, contains the entire blender electronics. The 16 line x 40 character back-lit display is extremely user friendly and provides intuitive text prompts. Up to 60 pre-programmed recipes are instantly accessible, enabling rapid "on-the-fly" order changes. The recipe select and order queue features allow a new job to be down-loaded instantly, including blend percentages, thickness, throughputs or job sizes. As the job progresses the operator can view setӔ and actualӔ blend recipes, material weights, kg/hr throughput, weight per length (g/m) and alarm...

カタログの2ページ目を開くTSM Control Systemsのすべてのカタログと技術パンフレット

-

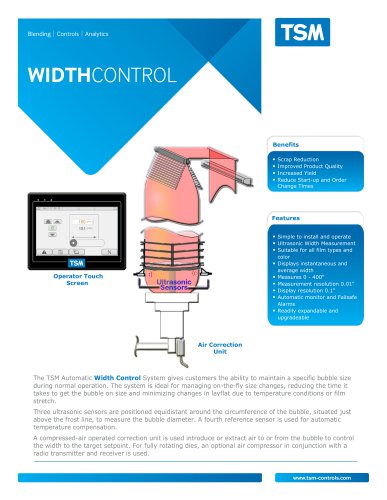

Width Control

2 ページ

-

Air Ring

2 ページ

-

LineView

2 ページ

-

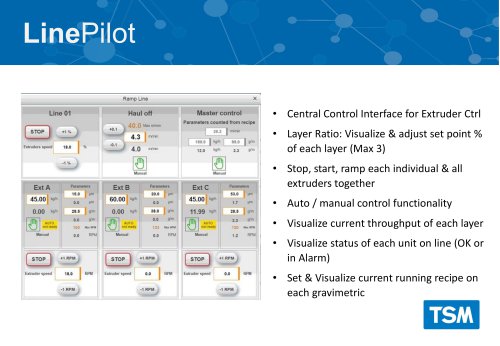

LinePilot

3 ページ

-

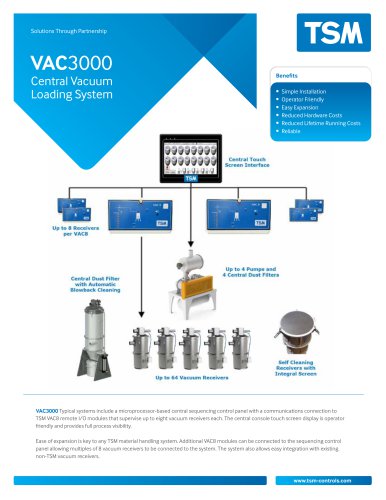

Vacuum Receiver

2 ページ

-

Venturi Mini Loader

2 ページ

-

Central Dust Filter

1 ページ

-

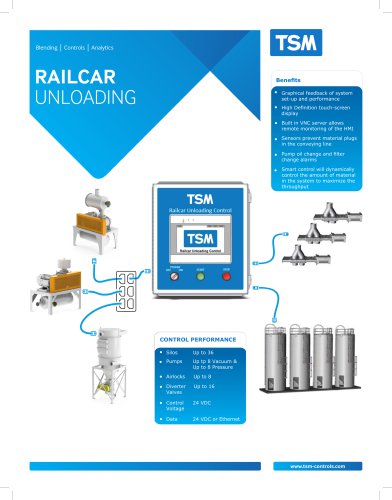

Automatic Unloaders

2 ページ

-

INSIGHT

4 ページ

-

TSM Material Drying

12 ページ

-

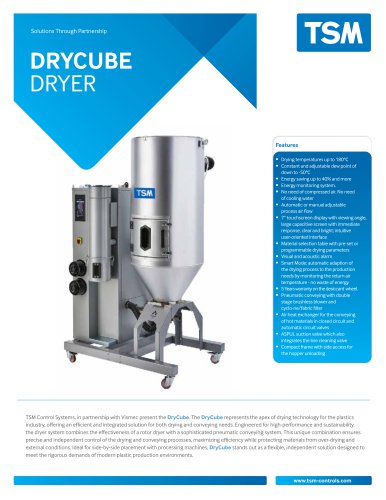

DryCube Dryer

2 ページ

-

Vertical Auger Mixer

2 ページ

-

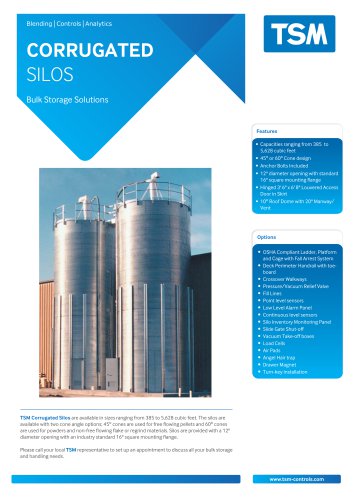

Storage Silos

2 ページ

-

Silo Dust Collectors

8 ページ

-

Mobile Storage Bin

2 ページ

-

Angel Hair Traps

2 ページ

-

Airbrator

3 ページ

-

Blender Upgrades

2 ページ

-

OPTI-X

2 ページ

-

OPTI-YIELD

2 ページ

-

OPTIMIX-1500 SERIES

2 ページ

-

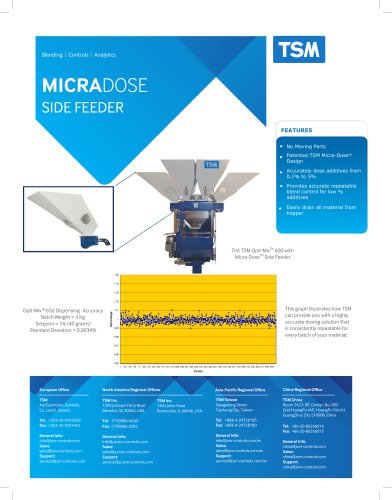

OPTIMIX-600 SERIES

2 ページ

-

Box Unloading Unit

2 ページ

-

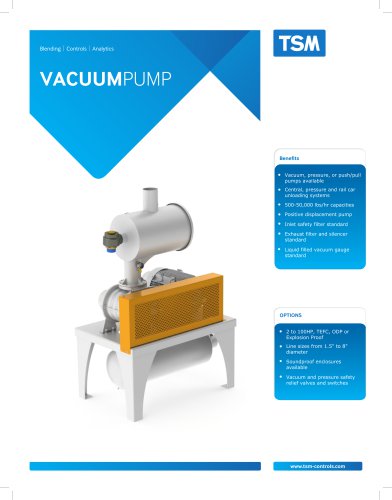

Vacuum Pump

1 ページ

-

Bulk Material Silos

2 ページ

-

OPTI-POW

2 ページ

-

OPTI-FLAKE

1 ページ

-

OPTI-FEED

2 ページ

-

OPTIMIX-200 Series

2 ページ

-

OPTI-BLEND

2 ページ

カタログアーカイブ

-

BOXUNLOADER

2 ページ

-

OPTIMIX 350

2 ページ

-

OPTIMIX 150

2 ページ

-

OPTIMIX 50

2 ページ

-

TSM

7 ページ

-

OPTI-MIX 3000

2 ページ

-

TSM Optimix Blender

2 ページ

-

TSM Multi-Blend

2 ページ

-

TSM Build Quality

2 ページ

-

TSM 1000D Drybatch

2 ページ