カタログの抜粋

Burst Tester 13-60 Series FEATURES • Three (3) models to choose from to measure Paper and film, Board and Corrugated, and Textiles • Pneumatic sample clamping pressure is measured with a transducer and displayed in bar/PSI • Compatible with GraphMaster™ PC based data collection and curve analysis software • Date of last calibration stored in memory (clamp pressure, bursting pressure, and height gauge) • Menus allow programming to meet predefined test methods and international standards • Number of test performed with diaphragm stored in memory BURST TESTING Burst Testers are used as a multi-directional tensile test to identify failure in the direction of least resistance for evaluating physical strength and fiber bond. Models are available to test a variety of materials. These models can also be fitted with a device to measure the deflection of the sample prior to burst. The rubber diaphragms with specific thickness and shore hardness must have a bulge versus pressure pattern within the tolerance of the standards related to the type of material tested. The Burst tester is designed to meet international standards for tests on paper, foils, paper boards, corrugated board, textiles etc. OPERATION The Burst Tester is designed for measuring the bursting strength of fabric materials subjected to an increasing hydrostatic pressure. This pressure is applied to a circular region of the specimen via an elastic diaphragm. The specimen is firmly held round the edge of this circular region by a pneumatic clamping device. When the pressure is applied, the specimen deforms together with the diaphragm. The bursting strength corresponds to the maximum pressure supported by the specimen before failure. Identical, in the principle to the multi-directional tensile test, Ball Burst Method for Fabrics, this measurement is independent from the cutting direction of the sample (machine or cross) since the failure naturally occurs in the least resistance direction. APPLICATIONS • Textiles, Fibers, Non-woven’s, Polyester, Fabrics and Felts etc. • Strength, stiffness, dye ability, resilience, fatigue elasticity, orientation and crystallinity. MEETS STANDARDS • ISO 2758, ISO 2759, , ISO 1328-2:1999, ISO 2960, ASTM D 3786 , ASTM D-774, BS 4768, TAPPI T403, TAPPI T807, TAPPI T810

カタログの1ページ目を開く

Pressure system: The hydrostatic pressure is transmitted to the diaphragm by a hydraulic jack associated with a frictionless ball-screw driven by a precision DC motor. The rotational speed and the position of the motor are servo-controlled by means of an optical encoder ensuring a perfect control of the fluid flow rate together with the determination of the displaced volume of fluid. Note: This measurement may be used to determine the profile of the resistance pressure of the rubber diaphragm itself versus the displaced volume of fluid. The corresponding values may then be subtracted from...

カタログの2ページ目を開くTesting Machines Incのすべてのカタログと技術パンフレット

-

10-48 Rotary Abraser

2 ページ

-

58-03 Densometers

1 ページ

-

GraphMaster

2 ページ

-

SD-200L

2 ページ

-

tear-tester

2 ページ

-

Dial Micrometers

2 ページ

-

Cobb Sizing Testers

1 ページ

-

Tensile Tester

3 ページ

-

Impact Tester

2 ページ

-

LabMaster Slip Friction

2 ページ

-

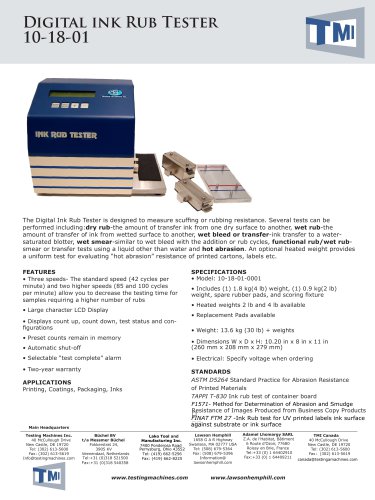

Ink Rub tester

1 ページ

-

Heat Sealer

4 ページ

-

Slip Friction tester

2 ページ

-

TS-4 Heat Sealer

3 ページ

-

Hygrometer

1 ページ

-

Moisture Meter

2 ページ

-

Photovolt

2 ページ

-

Bending Resistance

1 ページ

-

Internal Bond tester

4 ページ

-

Loop Tack tester

2 ページ

-

Probe Tack

2 ページ

-

Peel/Adhesion Tester

2 ページ

-

Dart Impact Tester

1 ページ

-

Canadian Freeness

1 ページ

-

Pulp Beater

1 ページ

-

Tear Tester

1 ページ

-

TS-12 Heat Sealer

2 ページ

-

portable hardness tester

1 ページ