カタログの抜粋

Electric Actuator/Slider Type ©2012 SMC Corporation All Rights Reserved (Clean Room Specification) [Clean Room Specification ] ISO Class 4 (Class 10)! • Built-in vacuum piping • Possible to mount the main body without removing the external cover, • Body-integrated linear guide Vacuum exhaust minimises external particle generation from the ball screw Step Motor (Servo/24 VDC) T Servo Motor (24VDC) Ball Screw Drive Series 11-LEFS AC Servo Motor (100/200/400 W) Type Ball Screw Drive Series 11-LEFS • High output motor (100/200/400 W) • Improved high speed transfer ability (Max.: 1,000 m/s) • High acceleration compatible (5,000 mm/s2) • Pulse input type/CC-Link direct input type/SSCNET III type • With internal absolute encoder (LECSB specification)

カタログの1ページ目を開く

Particle Generation Measuring Method_ The particle generation data for SMC Clean Series are measured in the following test method. ■Test Method (Example) Place the specimen in the acrylic resin chamber and operate it while supplying the same flow rate of clean air as the suction flow rate of the measuring instrument (28.3 L/min). Measure the changes of the particle concentration over time until the number of cycles reaches the specified point. The chamber is placed in an ISO Class 5 equivalent clean bench. ■Measuring Conditions - Clean bench (ISO Class 5 equivalent) ■ -|> Supply rate 15...

カタログの2ページ目を開く

Electric Actuator/Slider Type Series 7 l-Lcro Particle Generation Characteristics Step Motor (Servo/24 VDC), Servo Motor (24 VDC)

カタログの3ページ目を開く

Particle Generation Characteristics ISO Class 6 (Class 1000) upper limit upper limit Suction flow rate: 0 L/min Suction flow rate: 50 L/min" Suction flow rate: 80 L/min'-^k^iPP^ limit- Suction flow rate: 100 L/min

カタログの4ページ目を開く

Electric Actuator/Slider Type Ball Screw Drive/Ser/es 11-LEFS Model Selection Speed-Work Load Graph (Guide) : The following graph shows the values when positioning force is 100%.

カタログの5ページ目を開く

Speed-Work Load Graph (Guide) : The following graph shows the values when positioning force is 250%.

カタログの6ページ目を開く

Model Selection Series 7 l-Lcro Dynamic Allowable Moment This graph shows the amount of allowable overhang when the centre of gravity of the workpiece overhangs in one direction. When the centre of gravity of the workpiece overhangs in two directions, refer to the Electric Actuator Selection Software for confirmation, http://www.smcworld.com Load overhanging direction Me: Dynamic allowable moment [N-m] L : Overhang to the work load centre

カタログの7ページ目を開く

Electric Actuator/Slider Type_ Ball Screw Drive *8i™B"8" (Clean Room Specification] Clean series Vacuum type * Refer to the applicable stroke table. Applicable stroke table Note) CE-compliant products © EMC compliance was tested by combining the electric actuator LEF series and the controller LEC series. The EMC depends on the configuration of the customer's control panel and the relationship with other electrical equipment and wiring. Therefore conformity to the EMC directive cannot be certified for SMC components incorporated into the customer's equipment under actual operating...

カタログの8ページ目を開く

Electric Actuator/Slider Type . -f-f | rro Ball Screw Drive Series 7 I'LCrO [Clean Room Specification] ©Motor option ©Actuator cable type* *1 The standard cable should be used on fixed parts. For using on moving parts, select the robotic cable. *2 Only available for the motor type "Step ©Actuator cable length * Produced upon receipt of order (Robotic cable Refer to the specifications Note 2) on page 10 ©Controller type* *1 For details about controllers and compatible motors, refer to the compatible controllers *2 Only available for the motor type "Step motor" * When "Without controller" is...

カタログの9ページ目を開く

[Clean Room Specification] Note 1) Strokes shown in () are produced upon receipt of order. Note 2) Speed is changed by the work load. Check "Speed-Work Load Graph (Guide)" on page 5. Furthermore, if the cable length exceeds 5 m, then it will Note 3) Impact resistance: No malfunction occurred when the actuator was tested with a drop tester in both an axial direction and a perpendicular direction to the lead screw. (Test was performed with the actuator in the initial state.) Vibration resistance: No malfunction occurred in a test ranging between 45 to 2000 Hz. Test was performed in both an...

カタログの10ページ目を開く

Electric Actuator/Slider Type . -4-4 I rro Ball Screw Drive Series 7 I'LCrO [Clean Room Specification ] Note 1) Strokes shown in () are produced upon receipt of order. Note 2) Check "Speed-Work Load Graph (Guide)" on page 6. Furthermore, if the cable length exceeds 5 m, then it will decrease by up to 10% for each 5 m. Note 3) Impact resistance: No malfunction occurred when the actuator was tested with a drop tester in both an axial direction and a perpendicular direction to the lead screw. (Test was performed with the actuator in the initial state.) Vibration resistance: No malfunction...

カタログの11ページ目を開く

Series 11-LEFS Clean Room Specification Dimensions: Ball Screw Drive 3H9 ( 0 depth 3 +0.025 ) [mm] Model 11-LEFS16२-100 11-LEFS16२-100B 11-LEFS16२-200 11-LEFS16२-200B 11-LEFS16२-300 11-LEFS16२-300B 11-LEFS16२-400 11-LEFS16२-400B 65 34 4 n x ø3.4 100 8 D x 100 (=E) B Cable length ≈ 250 (L) A (Table traveling distance) Note 2) 37 39[(41)] 2[4] Stroke Origin Note 3) (2.4) 65 40 n D E 106 180 4 — — 206 280 6 2 200 306 380 8 3 300 406 480 10 4 400 40 27 20 Vacuum port M5 x 0.5 x 5 5.5 (72) 40 24 M4 x 0.7 thread depth 7 (F.G. terminal) 28 33 Body mounting reference plane Note 1) B Motor cable (2...

カタログの12ページ目を開く

Electric Actuator/Slider Type Ball Screw Drive Series 11-LEFS Clean Room Specification Dimensions: Ball Screw Drive 11-LEFS32 +0.030 5H9 ( 0 depth 5 ) Note 1) When mounting the electric actuator using the body mounting reference plane, set the height of the opposite surface or pin to 3 mm or more because of R chamfering. (Recommended height: 5 mm) Note 2) Distance within which the table can move when it returns to origin. Make sure a workpiece mounted on the table does not interfere with the workpieces and facilities around the table. Note 3) Position after return to origin. Note 4) The...

カタログの13ページ目を開くSMC のすべてのカタログと技術パンフレット

-

Serie HRR

64 ページ

-

Série VP/VG

33 ページ

-

Série XL

27 ページ

-

Série ACG/ARG/AWG

45 ページ

-

Série JXC5H/6H

36 ページ

-

LEJS100-X400 series

15 ページ

-

JMB series

13 ページ

-

JCM series

21 ページ

-

PF3A7*H

40 ページ

-

PF3W

34 ページ

-

Water Treatment

16 ページ

-

Digital Gap Checker

26 ページ

-

Vacuum Pad

16 ページ

-

One-touch Fittings

224 ページ

-

Soft Start-up Valve

16 ページ

-

Electric Actuator

272 ページ

-

Rotary Actuator

40 ページ

-

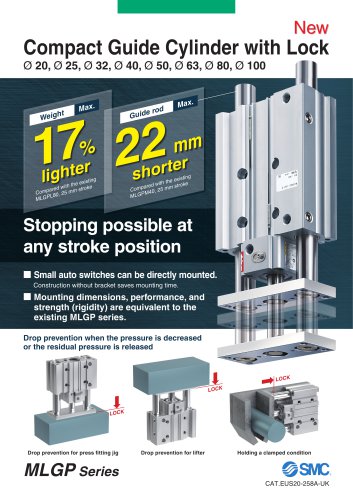

Compact Guide Cylinder

18 ページ

-

Compact Slide

24 ページ

-

Air Cylinder

124 ページ

-

LEFB, LEFG-BS series

180 ページ

-

JMGP series

16 ページ

-

ISO Cylinder

32 ページ

-

IZD10

20 ページ

-

IZH10

8 ページ

-

Fan Type Lonizer

28 ページ

-

Check Valves

4 ページ

-

3 port solenoid Valve

74 ページ

-

Vacuum Ejector Series ZM

20 ページ

-

Series ZL

20 ページ

-

Series CM2

92 ページ

-

Series IDGA/IDG

56 ページ

-

IDH-A

12 ページ

-

CP96-C96-B

74 ページ

-

CVQ

24 ページ

-

HY

52 ページ

-

VNA

10 ページ

-

Series MXY

28 ページ

-

Series MXP

39 ページ

-

Air Slide Table

132 ページ

-

Compact Cylinder Series CQ2

138 ページ

-

S0700

112 ページ

-

SYJ

96 ページ

-

SY - NEW

164 ページ

-

VF

60 ページ

-

C(D)55 series

24 ページ

-

C(D)Q2 series

216 ページ

-

MGP series

36 ページ

-

LECS series

16 ページ

-

LECPA series

4 ページ

-

KQ series

80 ページ

-

IDF series

16 ページ

-

ZP series

69 ページ

-

MHF series

32 ページ

-

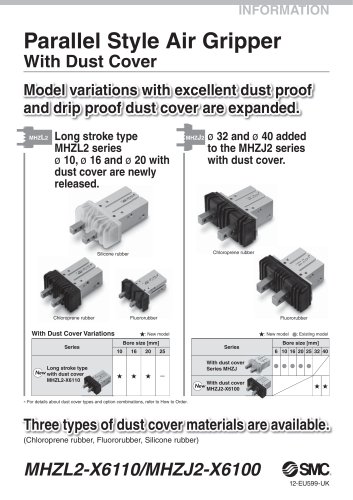

MHZ series

68 ページ

-

CRB series

44 ページ

-

MGJ series

7 ページ

-

AC series

98 ページ

-

VH series

14 ページ

-

LVA series

43 ページ

-

VDW series

28 ページ

-

LVM series

28 ページ

-

VX2 series

32 ページ

-

MXH series

32 ページ

-

MXF series

12 ページ

-

CXW series

48 ページ

-

CXS series

76 ページ

-

CQS series

40 ページ

-

CQM series

28 ページ

-

CLQ series

36 ページ