カタログの抜粋

Safety Network Controller

カタログの1ページ目を開く

Safety Network Controller Quick, easy and flexible integration of production line safety Scalable from large automotive production lines to small parts production lines Flexible safety system for large-scale production Interlocking between various machines Quick and easy safety program design Reduce time required for design Reduce time required for verification Efficient safety management and maintenance Minimize system downtime Reduce maintenance work

カタログの2ページ目を開く

Manufacturers require flexible systems for global production and high-mix production. System designs have become more and more complicated because these flexible systems need safety control according to control programs. However, it is also required to reduce design and maintenance time to efficiently build various systems. In order to meet these needs, we offer a new NX Safety Network Controller. Safety control for large systems High-speed safety control for mid-size systems Safety over CP Safety' EtherCAT Communication Control Safety CPU Unit Machine Au Machine Automation Controller...

カタログの3ページ目を開く

Safety Network Controller Flexible safety system for large-scale production EtherNet/IP for safety across the world Production systems have to meet worldwide standards because of the globalization of production. CIP Safety is a protocol for transmitting safety data via EtherNet/IP that is adopted by factory automation and robot manufacturers all over the world. Using CIP Safety, you can build globally standardized networks and simplify the global procurement of production systems. One connection using CIP Safety Safety systems for industrial robots are becoming increasingly used; networks...

カタログの4ページ目を開く

Standardize the safety system network for a large robot system System configuration In this example, devices and machines communicate via EtherNet/IP and CIP Safety in this system. Each process includes robots, safety light curtains, emergency stop switches, and other safety components. The NX-CSG Communication Control Unit and NX-SL5 Safety CPU Unit execute safety control programs in each process. CIP Safety is used for safety interlocking between processes and for building a safety control network across the system. PLC Hardware cabling * Understand the connection specifications of...

カタログの5ページ目を開く

Safety Network Controller Interlocking between various machines Simple configuration CIP Safety allows safety devices and standard devices to be mixed on the same network, providing safety interlock control between machines. CIP Safety robots and remote I/O terminals can be easily connected. Modular processes bring flexibility to line layouts The NX-CSG320 Communication Control Unit and NX-SL5 Safety CPU Unit exchange interlock signals with other machines while implementing safety control within the machine. Programs for machine control and safety control can be created for each machine....

カタログの6ページ目を開く

Two different networks in a single system The NX-SL5 Safety CPU Unit connected with the NX102 Machine Automation Controller enables the use of both EtherCAT + FSoE (Safety over EtherCAT) and EtherNet/IP + CIP Safety at the same time. In addition to interlock control within a machine via FSoE, safety interlock between machines can be implemented using CIP Safety. Integrated safety into high-speed machine control The NX-SL5 Safety CPU Unit combination with the NX102 Machine Automation Controller , provides both safety control and machine control with fast cycle times. By mounting the NX-SL...

カタログの7ページ目を開く

Safety Network Controller Improve design productivity The Automation Software Sysmac Studio provides various functionalities to reduce time required for production system design and safety program verification. Automatic Programming Online Functional Test Hardware/ software Safety program/ system operation check User-defined Function Block Offline Simulation Reduce time required for production system design Automatic Programming Create a truth table using input, output, and stop conditions of safety devices to automatically create a safety program for a simple machine. * Programs created...

カタログの8ページ目を開く

Implement safety management without experts and global standardization Offline Simulation Programs can be simulated on your PC, Sysmac Studio allows verification of programs without connecting hardware. Online Functional Test Online Functional Test enables operation of safety functions to be checked when the NX-SL5 Safety CPU Unit is online with Sysmac Studio. The test results can be output as a report along with the safety signature; the safety signature is displayed on the seven-segment display of the NX-SL5 Safety CPU Unit, and can easily checked if the configuration matches the report...

カタログの9ページ目を開く

Safety Network Controller Maintenance without PC No PC is required for maintenance, which reduces production system maintenance work and minimizes system downtime. Restore, ACR Hardware/ software Safety program/ system operation check Safety Data Logging Minimize system downtime Safety Data Logging An SD card containing logging settings is used for Safety Data Logging. When start trigger conditions are met, the specified device variables and exposed variables can be logged in a chronological order and output to the memory card. This function helps to quickly identify the cause of a sudden...

カタログの10ページ目を開く

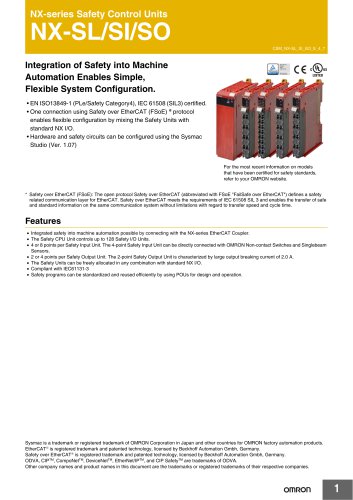

Existing products Choose a safety controller to suit your application. Product name NX Safety Controller Safety Control Unit NX-SL3/SI/SO Safety Network Controller Integration of safety into machine automation enables simple, flexible system configuration lFully integrate safety and standard control in one network by connecting with an NX EtherCAT Coupler Unit lSafety CPU unit: Up to 128 safety I/O units lSafety input unit: 8 or 4 safety input points per unit 4-channel units can be directly connected with Omron non-contact switches and single-beam sensors lSafety output unit: 2 or 4 safety...

カタログの11ページ目を開く

NX-series Communication Control Unit/Safety Control Units For the most recent information on models that have been certified for safety standards, refer to your OMRON website. Quick, easy, and flexible to integrate safety into production lines • Two built-in CIP Safety on EtherNet/IP ports • Up to 254 connections (NX-SL5700) • Up to 32 NX Units per Communication Control Unit • Innovative automation software Automatic Programming Safety Data Logging Online Functional Test • Meets EN ISO 13849-1 (PLe/Safety Category 4) and IEC 61508 (SIL3) * The Common Industrial Protocol (CIP™) is an...

カタログの12ページ目を開くOMRON/オムロンのすべてのカタログと技術パンフレット

-

D4F

8 ページ

-

D4GS-N

11 ページ

-

E4E2

5 ページ

-

Fiber Unit E32-LT/LD

4 ページ

-

G9SE Series

20 ページ

-

NX-SL/SI/SO

20 ページ

-

G9SP

28 ページ

-

G9SX-SM

24 ページ

-

G9SX-SM/LM

9 ページ

-

G9SX/G9SX-GS

49 ページ

-

G9SX-LM

28 ページ

-

G9SB

10 ページ

-

G9SA

16 ページ

-

DST1 Series

5 ページ

-

WS02-CFSC1-E

3 ページ

-

G9SA-300-SC

9 ページ

-

K8AK-AS

12 ページ

-

K8AK-AW

16 ページ

-

K8AK-VS

12 ページ

-

K8AK-VW

12 ページ

-

K8AK-PH

12 ページ

-

K8DS-PH

12 ページ

-

K8AK-PM

16 ページ

-

K8DS-PM

12 ページ

-

K8AK-PA

12 ページ

-

K8DS-PA

12 ページ

-

K8AK-PW

12 ページ

-

K8DS-PU

12 ページ

-

K8DS-PZ

12 ページ

-

K8AK-TS/PT

12 ページ

-

K8AK-LS

12 ページ

-

K8AK-TH

12 ページ

-

K2CM

16 ページ

-

SE

15 ページ

-

SAO

13 ページ

-

APR-S

6 ページ

-

XS5

25 ページ

-

XS2

29 ページ

-

F92A

4 ページ

-

GLS

3 ページ

-

TL-L

5 ページ

-

V680 series

68 ページ

-

V680S Series

68 ページ

-

MY

35 ページ

-

E3NC-L/-S

16 ページ

-

61F-GPN-BT / -BC

5 ページ

-

NE1A-SCPU Series

8 ページ

-

NE1A-SCPU0[]-EIP

8 ページ

-

NE0A-SCPU01

6 ページ

-

LY

14 ページ

-

G2R-[]-S

11 ページ

-

G7T

7 ページ

-

G2A

9 ページ

-

G2A-434

7 ページ

-

G2AK

7 ページ

-

MK-S

9 ページ

-

MK-S(X)

12 ページ

-

MM

17 ページ

-

MMK

14 ページ

-

G4Q

6 ページ

-

G7Z

9 ページ

-

G7J

10 ページ

-

E4B

12 ページ

-

E4A-3K

9 ページ

-

E4C-UDA

5 ページ

-

E6H-C

5 ページ

-

E6F-C

5 ページ

-

E6D-C

5 ページ

-

E6B2-C

5 ページ

-

E6A2-C

5 ページ

-

NL

8 ページ

-

VB

5 ページ

-

SC

5 ページ

-

D5F

5 ページ

-

D5A

8 ページ

-

E3S-GS3E4

3 ページ

-

E3S-R

11 ページ

-

E3S-A

21 ページ

-

E3S-CL

9 ページ

-

E3ZM-C

14 ページ

-

E3T Data Sheet

26 ページ

-

E3T Series

6 ページ

-

G5 Series

59 ページ

-

Sysmac Catalog

410 ページ

-

VT-X700

6 ページ

-

E5AC-T

8 ページ

-

CP1

12 ページ

-

CP1E

12 ページ

-

MS4800

40 ページ

-

VC-DL100

6 ページ

-

FZ4 Series

42 ページ

-

ZG2

16 ページ

-

ZS Series

32 ページ

-

ZW Series

24 ページ

-

E9NC-T

2 ページ

-

Vision System FH series

54 ページ

-

CompoNet

28 ページ

-

Code Reader/OCR

24 ページ

-

NT series

18 ページ

-

Safety Controller G9SP

28 ページ

-

Data Logger ZR-RX Series

12 ページ

-

DeviceNet Safety System

30 ページ

-

Switching Power Supplies

16 ページ

-

Photomicro Sensors

7 ページ

-

Displacement Sensors

4 ページ

-

H8PS Cam Positioner

32 ページ

-

FQ Vision Sensor

17 ページ

-

E2EF

8 ページ

-

FQ2 Smart camera

24 ページ

カタログアーカイブ

-

SMART REMOTE I/O

12 ページ

-

Sensor Accessories

38 ページ

-

REGULATION SOLUTIONS

24 ページ

-

Vision Systems

20 ページ

![NE1A-SCPU0[]-EIP](https://img.directindustry.com/pdf/repository_di/15954/ne1a-scpu0-eip-616667_1mg.jpg)

![G2R-[]-S](https://img.directindustry.com/pdf/repository_di/15954/g2r-s-616653_1mg.jpg)