ウェブサイト:

NIHON PISCO CO., Ltd.

ウェブサイト:

NIHON PISCO CO., Ltd.

グループ: 株式会社日本ピスコ

カタログの抜粋

Open-Close Flap Type Model Designation (Example) • The specially designed flaps, opening on either side, facilitate replacement or addition of cables. You can check the cables with the flaps down in place. › Excel at safety, durability and smooth movement with easy operation. › Capable of following every linear motion and compound motion of moving parts and protects cables and hoses. Calculation of Number of Links K (1) Size (Overall dimensions: H × W) Code 102 Code Size Free span S K 2 * HF in the chart above is the height which Plarailchain is able to pass through using under the length of free span with allowable expansion without load such as cables, hoses, etc. * Please make inquiries for special travel conditions. (3) Body color No code: Black W: Ivory (102, 202, 203, 204, 206 only) * Two kinds of brackets, one for fixed-end and the other for moving-end, are required. Select a designation code for the bracket from page 31. Open-Close Flap Type Model code n: Number of links (Figures below decimal point are raised to one positive number) S: Transfer stroke (mm or inch) a: πR + 2K (R: Bending radius (mm or inch), K: Play (mm or inch)) l: Distance from intermediate point (mm or inch) when the fixed-end is not in the middle of transfer stroke (when the transfer stroke is in the intermediate point : 0) P: Pitch (mm or inch) Max. transfer speed Plarailchain kg/m 0.12 Plarailchain material Bracket material /ft. mm inch mm inch mm inch mm inch mm inch mm inch m Before using PISCO products, be sure to read “Safety Instructions” and “Common Safety Instructions for Products in This Catalog” on page 13 to 16 and “Common Safety Instructions for Plarailchain” on page 24 to 29. Detailed Safety Instructions Setting fixed-end in the intermediate point of transfer stroke minimizes required number of Plarailchain. * Please refer to page 4 for the details of ECO-friendly products. Number of links is to be calculated by the following equation: The products listed in this page are ECO-friendly products. In case of ordering, please apply Model code in the following chart. Stainless steel SPCC with chrome plating (RoHS compliance) Service temp. range Operating environment Avoid using in acid/alkaline atmosphere or in hot water * Free span is the maximum length that Plarailchain can travel ho

カタログの1ページ目を開く

The products listed in this page are ECO-friendly products. * Please refer to page 4 for the details of ECO-friendly products. Brackets for Attachment of Plarailchain For fixed-end Hole type Pivot type Bracket type Orientation Outer periphery fix Model code Model code Model code Model code Model code Model code Model code Model code *1. The brackets for HPU102, which are different shape from above drawing, come in a set of moving-end and fixed-end brackets. * Select best-suited bracket for your application from above selection. Moving-end (the hole type) and fixed-end (the pivot type) must...

カタログの2ページ目を開く

Common Safety Instructions for Plarailchain Before selecting or using PISCO products, read the following instructions. Read the detailed instructions for individual series as well as the instructions below. Warning : 1. Never step on Plarailchain. Otherwise the chain may break and you will fall down. 2. When connecting, opening, closing, or carrying out maintenance and checks, hold the Plarailchain motionless. Otherwise the Plarailchain may run or fall under its own weight, thus doing injuries to you. 3. Pay attention to the flexing areas of the Plarailchain. You can get injured with your...

カタログの3ページ目を開く

Capability Diagram When total weight and max. diameter of cable hose, and transfer stroke are decided, please select a best suitable Plarailchain from the following capability diagram. The bending radius of Plarailchain must be larger than the one of cable/hose. Remarks 1. F = Free span = Length can be travelled horizontally 2. The diagram is a case when fixed-end is set to the center of transfer stroke. 3. ø: Maximum diameter of cable or hose to be stored.

カタログの4ページ目を開く

Safety Instructions for fixing storage items (tubings/ cables) This instruction is only examples to decrease the wear and tear of tubings/ cables inside the Plarailchain, but do not guarantee the effect for all types. As such, please conduct test use before actual operation. 1. Storage of tubings/cables 1. Please select tubings/cables with less than the minimum-bending radius of plarailchain. In addition, please fix crook of tubings/ cables before installing in Plarailchain. 2. When plenty of tubings/cables are installed, please use "divider" or "rack" inside in order to avoid spiral twist...

カタログの5ページ目を開く

2. Fixing of tubings/cables 1. Please fix tubings/cables as close as possible to the fixing bracket at both ends. Fixing far apart from the bracket causes looseness of the tubings/ cables. 2. Applying metal or resin plates with large surface friction resistance as fixture is acceptable. Tuck tubings/cables between base part and plate as shown below. Note) When a number of tubings/cables are fixed by a banding band together as shown below, some of them might not be touched and fixed by the band and causes loosening. Base part 3. When a number of tubings/cables are fixed by banding band,...

カタログの6ページ目を開く

Safety Instructions for safety device (guide-rail) installation When Plarailchain is used in long stroke or for long time even within the acceptable value of the free-span, the installation of safety device such as guide-rail can prevent sagging or loosening of Plarailchain. (However, the moving speed and acceleration speed are limited by the installation.) Moreover, since the following instruction is only rough indication, please contact PISCO for details. 1. Installation of guide-rail and guide-roller * Do not use guide-roller for the application of more than 1m/s moving speed. Please...

カタログの7ページ目を開く

3. Operation of multiple movements When biaxial running or multiple movements are operated as shown below, please confirm the specification and contact PISCO. 4. Other safety instructions for long stroke and multiple movements operation 1. Using safety devices such as guide-rail or guide-roller cause abrasion where the devices and Plarailchain contact. As such, please apply material made of low surface sliding resistance for the safety devices. Taping low friction sheet (such as super-high-molecular polyethylene sheet) to the all-contact face reduces the dust from abrasion and longer...

カタログの8ページ目を開くNIHON PISCO CO.のすべてのカタログと技術パンフレット

-

CTB series

1 ページ

-

FUS8 series

3 ページ

-

31 & 32 Series

20 ページ

-

Vacuum Pad Soft Series

86 ページ

-

VP series

106 ページ

-

CHA series

8 ページ

-

Gripper Series

15 ページ

-

SVB Series

50 ページ

-

SVA series

13 ページ

-

SVR series

31 ページ

-

NSB series

8 ページ

-

BV series

8 ページ

-

HV series

5 ページ

-

Plarailchain SC

15 ページ

-

Plarailchain SPO

12 ページ

-

Plarailchain SP

14 ページ

-

HPO

12 ページ

-

PJN series

15 ページ

-

KJNC series

15 ページ

-

SSJS series

6 ページ

-

Stainless SUS316

13 ページ

-

UE series

12 ページ

-

FB series

1 ページ

-

CTA series

1 ページ

-

SFTN series

2 ページ

-

SET series

1 ページ

-

SFT series

14 ページ

-

ULF series

12 ページ

-

UCQ series

2 ページ

-

UQ series

12 ページ

-

NB series

12 ページ

-

NA series

12 ページ

-

UD series

12 ページ

-

UBS series

12 ページ

-

UBT series

12 ページ

-

UC series

1 ページ

-

UB series

12 ページ

-

AK/AS series

26 ページ

-

NK series

18 ページ

-

Brass Series

30 ページ

-

V-0 series

27 ページ

-

EG Series

27 ページ

-

PP Fitting series

12 ページ

-

PP Series

26 ページ

-

AP series

18 ページ

-

SL series

16 ページ

-

P-SUS series

33 ページ

-

NS series

24 ページ

-

SSP series

8 ページ

-

ATS series

6 ページ

-

Air Filter

20 ページ

-

Combination Unit Series

25 ページ

-

SFU series

9 ページ

-

JP series

15 ページ

-

ET series

11 ページ

-

EQ series

19 ページ

-

CVLU series

21 ページ

-

CV series

24 ページ

-

JN series

25 ページ

-

JSD series

10 ページ

-

JS Low-Flow series

17 ページ

-

JSC series

13 ページ

-

JS series

30 ページ

-

MA series

16 ページ

-

RH series

16 ページ

-

R series

16 ページ

-

PS series

16 ページ

-

L series

41 ページ

-

FUS20

7 ページ

-

GP series

13 ページ

-

VUS12 series

2 ページ

-

VUS21 series

14 ページ

-

VUS8-S series

22 ページ

-

JSD series

10 ページ

-

JK series

10 ページ

-

RVFUP series

6 ページ

-

VLF series

16 ページ

-

VFL series

8 ページ

-

VF series

22 ページ

-

ECV series

8 ページ

-

VPLFC, VPLFD series

17 ページ

-

VPKE series

4 ページ

-

RPV06 Series

8 ページ

-

VZ Series

34 ページ

-

VX Series

42 ページ

-

VQ Series

4 ページ

-

VN Series

40 ページ

-

VK series

53 ページ

-

VJ Series

34 ページ

-

VG series

21 ページ

-

VRL series

17 ページ

-

VVV series

11 ページ

-

VLS series

4 ページ

-

VM | VC series

28 ページ

-

VY series

24 ページ

-

VB series

11 ページ

-

VH | VS series

28 ページ

-

VPHMP series

12 ページ

-

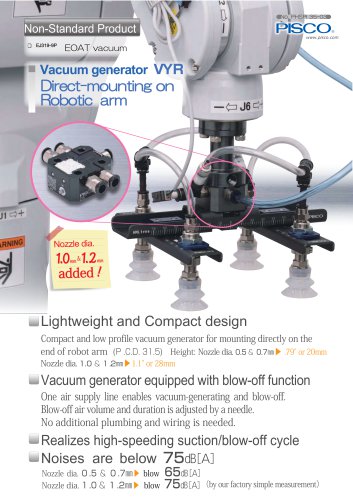

VYR series

5 ページ

-

HS series

13 ページ

-

HML series

14 ページ

-

VRG series

18 ページ

-

Dry Unit Series

33 ページ

-

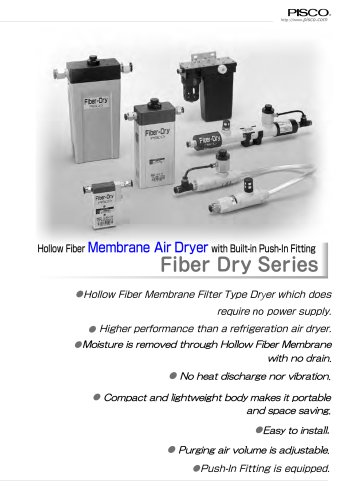

Fiber Membrane Air Dryer

12 ページ

-

VLM series

12 ページ

-

VSPE series

5 ページ

-

VT series

21 ページ

-

PB series

13 ページ

-

JSG series

17 ページ

-

pararel

3 ページ

-

fitting

4 ページ

-

BJSU series

4 ページ

-

SC

15 ページ

-

SPO

12 ページ

-

SP

13 ページ

-

RPV pump

8 ページ

-

Pre-set

6 ページ

-

Flange

13 ページ

-

HML

14 ページ

-

VYR

5 ページ

-

EOAT VRG | VMG series

18 ページ

-

VPLFC

17 ページ

-

SVB

172 ページ

-

SVR

39 ページ

-

8mm Sensor

22 ページ

-

Vacuum Filter

28 ページ

-

Fall Prevention

18 ページ

-

Vacuum Pen

21 ページ

-

Push-Rod Release

4 ページ

-

cylinder

22 ページ

-

FDAbellows

6 ページ

-

Oval

80 ページ

-

sponge

50 ページ

-

mark-free

34 ページ

-

flat

42 ページ

-

Ultrathin

34 ページ

-

packaging bag

13 ページ

-

multi-bellow

46 ページ

-

bellows pad

74 ページ

-

Skid proof pad

42 ページ

-

soft bellow pad

60 ページ

-

soft pad

66 ページ

-

VRL

17 ページ

-

VH VS VC VUM VU VY VB

336 ページ

-

VZ

34 ページ

-

VX

42 ページ

-

VVV

11 ページ

-

VQ

42 ページ

-

VN

40 ページ

-

VLS

4 ページ

-

VLM

12 ページ

-

VK

53 ページ

-

VJ

34 ページ

-

VG

21 ページ

-

Vacuum Tube

12 ページ

-

Twin Coiling

12 ページ

-

Tube Cutter

12 ページ

-

Polyurethane Tube

12 ページ

-

Nylon Tube Series

12 ページ

-

Multi-core Planar Tube

12 ページ

-

Insert Ring

12 ページ

-

Fluororesin (PFA) Tube

14 ページ

-

UL series

12 ページ

-

Anti-spatter Tube

12 ページ

-

Tube Fitting PP Series

26 ページ

-

Tube Fitting Mini Series

41 ページ

-

K series

30 ページ

-

Stop Fitting Series

16 ページ

-

Rotary Joint Series

16 ページ

-

Minimal Fitting Series

20 ページ

-

Main Block Series

24 ページ

-

Light Coupling Series

24 ページ

-

High Rotary Joint Series

16 ページ

-

Connector Series

16 ページ

-

Color Cap

12 ページ

-

Vacuum EOAT Kit HML

14 ページ

-

Vacduum gripper

18 ページ

-

SSNC series

13 ページ

-

SJSC series

24 ページ

-

Speed Controller Series

32 ページ

-

KJSC series

17 ページ

-

Silencer Series

13 ページ

-

Pressure Gauge Series

13 ページ

-

Miniture quick-exhaust

17 ページ

-

Check Valve

4 ページ

-

Parallel Gripper

6 ページ

-

JSG

17 ページ

-

GENERAL

106 ページ

-

Mechanical Valve Series

19 ページ

-

Ball Valve Series

19 ページ

-

Hand Valve Series

15 ページ

-

Change Valve

11 ページ

-

SVA21 Series

21 ページ

-

P Series

71 ページ

-

SVA20 Series

43 ページ

-

RegulatorPL031821m

12 ページ

-

BJSU series

6 ページ

-

NP68-01e

17 ページ