カタログの抜粋

ή MULTIPLE WINDOW DISPLAY MULTIPLE ROBOT CONTROL Dynamic Next-Generation Controller Features robust PC architecture. Provides system-level control for robotic workcells. Highly exible eldbus support. Easy connection to information infrastructure through standard network options. Fast processing speed provides smooth interpolation. Easy maintenance with reducer status check function, enhanced troubleshooting and alarm recovery, and 20% improvement in MTTR. Patented multiple robot control (up to 8 robots/72 axes), as well as I/O devices and communication protocols. Dynamic interference zones protect robot arm and provide advanced collision avoidance. Compliant to ANSI/RIA 15.06-1999 and other relevant ISO and CSA safety standards. Includes dual-channel E-Stop functionality, integrated speed monitoring and manual brake release for robot. Optional Category 3 functional safety unit. Often eliminates need for separate PLC and human machine interface (HMI). Delivers signi cant cost savings at system level, while decreasing workcell complexity and improving overall reliability. Connections to controller cabinet are made through the back of the unit, optimizing oorspace. DX100 control cabinet allows for up to three external axes and can be remote- mounted. DXM100 supports up to two external axes. Top- or side-mount expansion options available for DX100 controller only. Advanced Robot Motion (ARM) control provides high performance. Best-in- class path planning dramatically reduces teaching time. Small, lightweight Windows > DXM100 CONTROLLER Convenient compact ash slot and USB port facilitate memory backups. > CE programming pendant features color touch screen with multiple window display capability. Unique cross-shaped navigation cursor reduces teaching time. All operator controls are located on pendant. Program le names can be up to 32 characters long. Conserves power during robot idle time, providing up to 25% energy savings. >

カタログの1ページ目を開く

Dimensions DX100: 800 (w) x 1000 (h) x 650 (d) (31.5" x 39.4" x 25.6")DXM100: 800 (w) x 600 (h) x 650 (d) (31.5" x 23.6" x 25.6") Approximate Mass 150-250 kg (330.8-551.3 lbs.) Cooling System Indirect cooling Ambient During operation: 0 to 45а C (32 to 113а F) Tem per a ture During transport and storage: -10 to 60а C (14 to 140а F) Relative Humidity 90% max. non-condensing > 1000 Primary Power Requirements 3-phase, 240/480/575 VAC at 50/60 Hz Digital I/O Standard I/O: 40 inputs/40 outputs consisting of 16 system NPN - Standard inputs/16 system outputs, 24 user inputs/24 user outputs PNP -...

カタログの2ページ目を開くMOTOMAN/安川電機のすべてのカタログと技術パンフレット

-

SDA10D

2 ページ

-

SIA20D

2 ページ

-

SIA10D

2 ページ

-

SDA20D

2 ページ

-

SDA10F

2 ページ

-

SDA20F

2 ページ

-

SDA5F

2 ページ

-

SIA10F

2 ページ

-

SIA20F

2 ページ

-

SIA30D

2 ページ

-

SIA50D

2 ページ

-

SIA5D

2 ページ

-

SIA5F

2 ページ

-

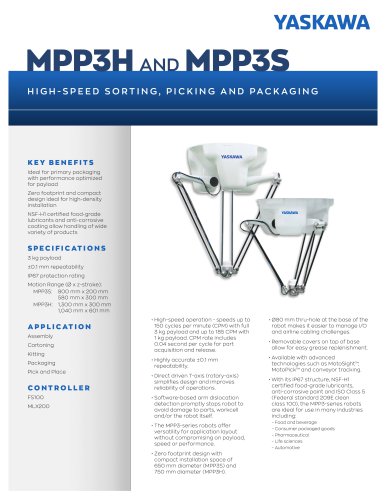

MPP3H AND MPP3S

2 ページ

-

YRC1000

2 ページ

-

HC10DTP

2 ページ

-

AR700

2 ページ

-

AR1440

2 ページ

カタログアーカイブ

-

MA3120

2 ページ

-

MH50 II-20

2 ページ

-

MA2010

2 ページ

-

HP20

2 ページ

-

VA1400 II

2 ページ

-

MH3BM

2 ページ

-

MS165/MS210

2 ページ

-

MA1440

2 ページ

-

Motoman robots

7 ページ

-

NX100 Controller

2 ページ

-

FS100 Controller

2 ページ

-

HP20RD

2 ページ

-

HP20F

2 ページ

-

HP20D-A80

2 ページ

-

YSH850L

2 ページ

-

MPP3

2 ページ

-

MHJF

2 ページ

-

MH6F

2 ページ

-

MH5LS(MLX100)

2 ページ

-

MH5F

2 ページ

-

MH3F

2 ページ

-

MH5S

2 ページ

-

Motoman FabWorld II

2 ページ

-

Motoman MH50-20 Robot

2 ページ