カタログの抜粋

MICROSTEPPING DRIVER MAIN FEATURES: • Current: 0.35 to 2.0 Amps Peak • Step resolution: Full Step, 2x, 4x, 8x, 2 wires with • Speed: (step frequency: 25 kHz) • Inputs: Step Clock, Direction, Disable/Enable • Inputs: Step Clock, Direction, Disable/Enable • Inputs: Step Clock, Direction, Disable/Enable A DB-9 female connector cable receives power and provides the control connections for the R208 Driver. Active signals are optically isolated. An open-collector drive is required to provide pulses for Step, levels for Direction and Disable/Enable. Each R208 comes with a DB-9 connector with flying leads, and a 4 pin connector with flying • 090-00019 DB-9 cable (comes with unit) • 090-00018 motor cable (comes with unit) • Also Requires (not included): PC, step motor, function or pulse generator, controller • Connect the power supply and use a voltmeter to read from pin 7 to the potentiometer in the R208 Rotate potentiometer (CW will decrease current, CCW will increase current) Voltmeter should read the following: Voltage Vref = (I - 0.14)/1.554, where I is desired current in Amps/Phase, and this formula accounts for multiplying 1.4 times to get peak current. Example: if motor is rated at 0.8 Amps/Phase, CHANGING STEP RESOLUTION: Pins 2 and 3 are used to change microstepping. When one pin, both or no pins are connected to Pin 7, this will change the step resolution accordingly: are used to preset the step contact closure to ground

カタログの1ページ目を開く

Key selling features: • Extremely Low Cost • Compact Size • Low Power Dissipation • Higher Torque DETAILED FEATURES: • Operating temperature: -20 to 50 °C • Humidity range: 0 to 95% (non-condensing) • Step pulse timing: • Minimum step pulse width: 20 microseconds (20x10-6) • Minimum step low time: 20 microseconds • Maximum power-down recovery time 20 milliseconds • Max step frequency = 1 / [min. step pulse width + min. step low time] = 25 kHz • More efficient and better torque output: Torque Comparison 1.8˚ Step Motor, 24vDC, 1.4 Amp/Phase, 1/8 Stepping 40 R208 Competitor A Competitor B...

カタログの2ページ目を開く

COMMON TECH SUPPORT QUESTIONS / RMA ISSUES: BURNED OR BLOWN DRIVER (LOW INDUCTANCE): Motors with inductance levels of 1.5 mH or less will cause the drivers to blow or not work as expected. Torque will drop because the output current is less than expected. (A limitation of the driver chip) Check holding current and running current. It could be too high. Check wiring. Motor phases could be crossed (A is in B or B Bar, etc) Check connection between motor and drive. If, for example, the "A" and "A Bar" connection is actually connected to an "A" phase wire and a "B" phase wire, then the driver...

カタログの3ページ目を開くLin Engineeringのすべてのカタログと技術パンフレット

-

SilverPak 17D Plus

1 ページ

-

5818 ?Super Torque

1 ページ

-

208 ? Standard Motor

1 ページ

-

High Torque

1 ページ

-

Why Lin 2014

2 ページ

-

MICROSTEPPING DRIVER

2 ページ

-

8618 STANDARD MOTOR

1 ページ

-

5618 STANDARD MOTOR

1 ページ

-

5609 STANDARD MOTOR

1 ページ

-

4018 STANDARD MOTOR

1 ページ

-

4109 GOLD LINE MOTOR

1 ページ

-

3518 STANDARD MOTOR

1 ページ

-

211 COMPACT MOTOR

1 ページ

-

208 COMPACT MOTOR

1 ページ

-

SilverPak 17C/CE

2 ページ

-

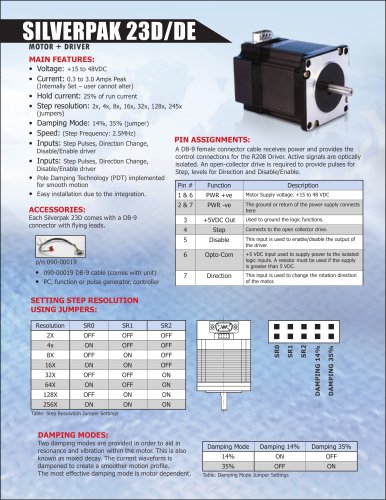

SILVERPAK 23D/DE

3 ページ

-

SilverPak 23C

2 ページ

-

GOLD LINE MOTOR

2 ページ

-

1.8° SIZE 11

2 ページ

-

STANDARD MOTOR

2 ページ

-

SilverPak 17T

3 ページ

-

1.8º SIZE 14

2 ページ

-

Lin Catalog 2006

100 ページ

カタログアーカイブ

-

STANDARD MOTOR 5609

2 ページ

-

STANDARD MOTOR 4018

2 ページ

-

STANDARD MOTOR 8618

2 ページ