カタログの抜粋

Powering your potential Kawasaki Robot series Extra large payload robots up to 1,500 kg Kawasaki Heavy Industries, Ltd. ROBOT DIVISION Tokyo Head Offlce/Robot Division 1-14-5, Kaigan, Minato-ku, Tokyo 105-8315, Japan Phone: +81-3-3435-2501 Fax: +81-3-3437-9880 Akashi Works/Robot Division 1-1, Kawasaki-cho, Akashi, Hyogo 673-8666, Japan Phone: +81-78-921-2946 Fax: +81-78-923-6548 Global Network Kawasaki Robotics (USA), Inc. 28140 Lakeview Drive, Wixom, MI 48393, U.S.A. Kawasaki Robotics (UK) Ltd. Unit 4 Easter Court, Europa Boulevard, Westbrook Warrington Cheshire, WA5 7ZB, United Kingdom Phone: +44-1925-71-3000 Fax: +44-1925-71-3001 Kawasaki Robotics GmbH 29 Sperberweg, 41468 Neuss, Germany Phone: +49-2131-34260 Fax: +49-2131-3426-22 Kawasaki Robotics Korea, Ltd. 43, Namdong-daero 215beon-gil, Namdong-gu, Incheon, 21633, Korea Phone: +82-32-821-6941 Fax: +82-32-821-6947 Kawasaki Robotics (Tianjin) Co., Ltd. 1-2/F, Building 6, No.19 Xinhuan Road, TEDA, China Phone: +86-22-5983-1888 Fax: +86-22-5983-1889 Kawasaki Motors Enterprise (Thailand) Co., Ltd. (Rayong Robot Center) 119/10 Moo 4 T.Pluak Daeng, A.Pluak Daeng, Rayong 21140 Thailand Phone: +66-38-955-040-58 Fax: +66-38-955-145 https://robotics.kawasaki.com/ Kawasaki Robot CAUTIONS TO BE TAKEN TO ENSURE SAFETY •For those persons involved with the operation / service of your system, including Kawasaki Robot, they must strictly observe all safety regulations at all times. They should carefully read the Manuals and other related safety documents. •Products described in this catalogue are general industrial robots. Therefore, if a customer wishes to use the Robot for special purposes, which might endanger operators or if the Robot has any problems, please contact us. We will be pleased to help you. •Be careful as Photographs illustrated in this catalogue are frequently taken after removing safety fences and other safety devices stipulated in the safety regulations from the Robot operation system. ] Materials and specifications are subject to change without notice.

カタログの1ページ目を開く

Maximum payload 1,500 kg Incorporating a compact profile design with long reach and high wrist torque The “M series” – this powerful robot developed by Kawasaki Heavy Industries, a pioneer of industrial robot manufacture, has a maximum payload of 1,500 kg. Its superior design gives it the power to lift and manipulate heavy loads with great ease and high accuracy. Kawasaki’s own mechanism makes the waist more compact and allows it to support a larger payload capacity. Features Compact profile The MX adopts a new link structure for the JT3 (upper and lower arms), while the MG adopts...

カタログの2ページ目を開く

] : The maximum ranges of motion depend on the payload and the torque.

カタログの3ページ目を開く

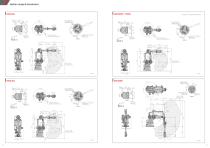

Motion range & dimensions Interference radius around the rotational axis Working range based on point P Interference radius around the rotational axis 481 Working range based on point P Working range based on point P 3,502 Working range based on point P Interference radius around the rotational axis

カタログの4ページ目を開く

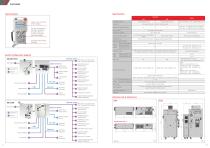

Motion range & dimensions The E-Controller, with unprecedented quality and compact size, was created in response to customer demand. Kawasaki’s collaboration of past achievements and experience has lead to the development of the most technically advanced controller available. This industry leading design provides increased performance and easy operation that exceeds expectations. Small footprint of the E controller makes it easy to achieve high-density layouts. And overall volume has been reduced greatly compared with the previous model. As a result, an upright-position installation or...

カタログの5ページ目を開く

Teach pendant Specifications System configuration diagram MX/MT+E04 DIO board Optional device Optional board Fast check mode switch Brake release switch Transformer unit Teach pendant » software Ethernet Terminal Vision controller DIO board: 32 points each max. 3 boards (96 points) DeviceNet board, master/slave CC-Link board, master/slave PROFIBUS board, master/slave PROFINET board, master/slave Ethernet/IP board, master/slave CAN open board, slave EtherCAT board, master/slave Conveyor I/F board Cubic-S (area monitor /speed monitor) External view & dimensions Optional board Optional...

カタログの6ページ目を開くKawasaki Robotics GmbHのすべてのカタログと技術パンフレット

-

Lineup Overview

2 ページ

-

MS005N

2 ページ

-

Kawasaki Robot K series

12 ページ

-

Palletizing robots

6 ページ

-

MC series

2 ページ

-

F60 Controller

2 ページ

-

Controllers

1 ページ

カタログアーカイブ

-

Controller

1 ページ

-

MC004N

5 ページ

-

M-Series

5 ページ

-

Z-Series

7 ページ

-

CX series

2 ページ

-

R-Series

7 ページ

-

Lineup

8 ページ

-

MC/MS-Series

5 ページ

-

Overview

2 ページ

-

K-Roset

4 ページ

-

Cubic-S

3 ページ

-

Palletizer

5 ページ

-

Y-Series

5 ページ

-

RA-Series

5 ページ

-

RS80N

2 ページ

-

RS50N

2 ページ

-

RS30N

2 ページ

-

RS20N

2 ページ

-

RS10L

2 ページ

-

RS10N

2 ページ

-

RS06L

2 ページ

-

RS05L

2 ページ

-

RS05N

2 ページ

-

RS03N

2 ページ

-

RS15X

2 ページ

-

FSJ

4 ページ

-

PC Roset

2 ページ

-

Y Series

6 ページ

-

Z-Series

8 ページ

-

R series

8 ページ

-

E controller

2 ページ

-

D-Controller

6 ページ

-

EDU Pack

2 ページ

-

Image Catalogue

5 ページ

-

Line up

8 ページ