カタログの抜粋

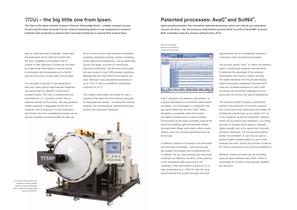

Hard work wins What you should know about Ipsen’s vacuum technology.

カタログの1ページ目を開く

Where does the use of Ipsen vacuum technology make sense? Basically wherever special steel grades are to be produced by hardening or where it is desired to keep as large as possible a number of usage options open. For example, vacuum furnaces enable the braising of joints which can be thermally or mechanically highly loaded. Therefore, the most important applications for Ipsen vacuum technology are in the aviation and aerospace industries, in jet engine assembly, nuclear technology, medical technology, not to mention contract heat treatment shops or automotive engineering. The advantages of...

カタログの2ページ目を開く

Peak current is particularly expensive. It arises unavoidably when starting a cooling gas fan at the beginning of high pressure gas quenching – regardless of whether a direct or soft start is used. During a conventional start, the motor can only be started after a pressure of some 1,000 mbar absolute is achieved and then moreover only with a current 10 or 5 times the rated current. This is where Ipsen’s patented LCP-Start (Low Current Power Start) really saves energy. Its use means that current consumption in the peak load range is, at 2.5 times the rated current, drastically reduced. So...

カタログの3ページ目を開く

AvaC®, acetylene low pressure carburisation, is a proven alternative to conventional carburisation processes. The advantages in comparison with gas carburisation are obvious: AvaC® offers, alongside a completely oxide-free surface, the highest possible level of carbon transfer. The process can be easily controlled, while at the same time yielding highly reproducible results – amongst other things, particularly uniform carburisation, even with complex geometries such as blind holes. In addition it stands out because of its favourable environmental credentials – both process gas and energy...

カタログの4ページ目を開く

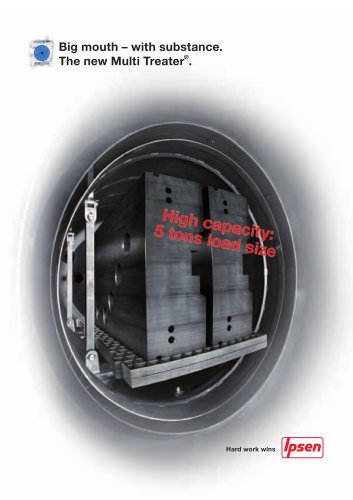

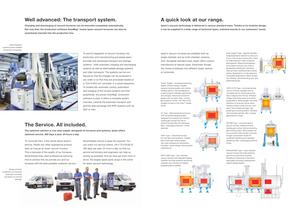

Ipsen’s vacuum furnaces are available both as single chamber and as multi-chamber versions. And: Alongside standard sizes, Ipsen offers custom manufacture of special types. Essentially though, the choice is between two different types: vertical or horizontal. A quick look at our range. Ipsen’s vacuum technology is delivered in various standard sizes. Thanks to its modular design, it can be supplied in a wide range of technical types, matched exactly to our customers’ needs. Multi Treater® Type – Specific benefits: Suspended batch table for a load up to 5 tons. The furnace comes with a...

カタログの5ページ目を開く

Hard work wins For over 60 years Ipsen has been finding new ways of producing steel of ever improving quality using the company’s innovative, proprietary technologies, such as the AvaC® process (low-pressure carburising), the SolNit® process (solution nitriding) and the recently developed HybridCarb process (gas carburising with recycling). Ipsen’s offerings combine the highest performance with outstanding reliability, which perhaps explains why our furnaces and heat treatment equipment enjoy an excellent reputation all over the world. Our customers work in automotive, aviation and...

カタログの6ページ目を開くIpsen International GmbHのすべてのカタログと技術パンフレット

-

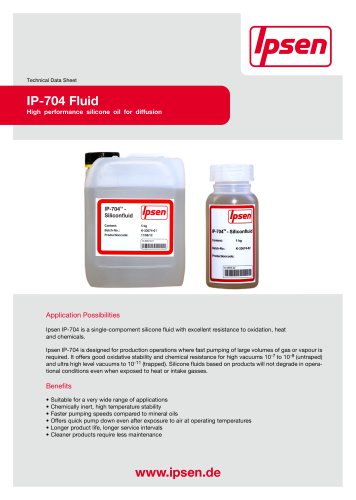

IP-704 Fluid

2 ページ

-

Ipsen Brazing

2 ページ

-

Ipsen Titan

9 ページ

-

Ipsen HybridCarb

3 ページ

-

Ipsen AutoMag® 4.0

3 ページ

カタログアーカイブ

-

Ipsen Multi Treater

5 ページ

-

Carb-o-Prof® 4.0

3 ページ

-

Ipsen SolNit

3 ページ

-

Ipsen Turbo²Treater

6 ページ

-

Wind Energy

5 ページ

-

Ipsen SuperQuench

3 ページ