ウェブサイト:

HAIDA EQUIPMENT CO., LTD

ウェブサイト:

HAIDA EQUIPMENT CO., LTD

カタログの抜粋

The manual operation of Micro BCT Tester Introduction Thank you for choosing our products! We not only provide high quality products, but also reliable after-sales service. In order to ensure the safe of the operator and keep the machine well, please read the Operation Manual carefully before operating the instrument; pay more attention to the operating notes. This operating manual will illustrate the design principles、design criteria、structure、 operation specification、calibration、maintenance、some failure case and solutions、electrical diagram, and so on. If this operating manual ever mentioned some expressions like “test requirement” 、“standards”, please note all of them would only be for your reference. Please review relevant standards or data by yourself if you disagree with this. Special Statement: ● This operating manual can’t be treated as the proof to ask any illegal requirement to our company. ● The interpretation of this manual owes to our company. Haida International Equipment Co., Ltd Phone:0769-3881029 Fax:0769-89280809 Service phone:0769-88838300 Website

カタログの1ページ目を開く

The manual operation of Micro BCT Tester Di re c to r y Attention on safety --------------------------------------------------------------------------------------------3 Ⅰ . O v e r v i e w ------------------------------------------------------------------------------------------- 4 Ⅱ . D e s i g n C r i t e r i a -------------------------------------------------------------------------------------- 4 Ⅲ . Equipment Instruction--------------------------------------------------- 5-10 1 . S t r u c t u r e...

カタログの2ページ目を開く

The manual operation of Micro BCT Tester Warning: //l\ This shows that if you don't follow the project, may damage the apparatus. This shows that the project is possible to impact test results and quality.

カタログの3ページ目を開く

The manual operation of Micro BCT Tester Ⅰ. Overview 1. Usage: The machine is designed to test carton box or other container compression strength, it can also do stacking test. The test results can be referenced to stack boxes in factory and design your products. 2. Principle: It’s electric value display, combines with motor driving screw to shift down the up pressure plate to compress the sample, display the force value automatically through Load Cell. Design standard: GB/T 6543,8168,4857.4,SN/T 0262,TAPPI-804,JIS-Z0212、ASTM-D642 and other test standards.

カタログの4ページ目を開く

The manual operation of Micro BCT Tester

カタログの5ページ目を開く

The manual operation of Micro BCT Tester 2. Control panel (Figure 2) ( Figure 2) Instruction: Power:Power switch Peak: Record the max value before press test, otherwise can not save. Note: Please not press it ( when do stacking test) Print:Print the test results. Function:Adjust and set date, time, value and stacking test, press it to save test results after test. Unit:Switch the unit KG,LB,N. Zero: Clear the test results and value for do next test. High speed:Increase the up and down speed. Test:Press this key enter into test condition. Up,Down:Make machine up and down. Stop :Stop test....

カタログの6ページ目を開く

3. Date、Time and Stacking Test setting (Chart 1) The manual operation of Micro BCT Tester Turn on【Power】 Press【Print】 Turn on【power】 ,long press 【Print】over 3 second 【Peak】 【Print】 【Function】 【Print】 【Peak】 【Function】 【Print】 【Peak】 【Function】 【Print】 【Peak】 【Function】 【Print】 【Peak】 【Function】 【Print】 【Peak】 Input password , Press【Function】 to move, 【Print】to increase value;Press 【Peak】 confirm, then press 【Print】 to three times,choose CAL3,press 【Peak】to confirm. Date setting (Y/M/D) Press【Function】to move, 【Print】to increase value; 【Peak】to confirm Time setting (H/M/S) Press【Function】to...

カタログの7ページ目を開く

The manual operation of Micro BCT Tester Ⅳ . Eq u i p m e n t I n s t a l l a t i o n 1. Power : please configure correct power according to our nameplate, power is AC 220、50Hz. Danger: ■Error range of the input voltage ±10%, ! grounded to prevent damage to theismachineand ensure that the machine should be properly leakage. 2. Operating environment conditions:room temperature is 0~55°Cand humidity <80%RH. 3. This instrument should be placed on the level ground to install and locate. 1.Sample preparation: it is better to prepare 5 pieces of sample and mark as following: ● Marks for packages:...

カタログの8ページ目を開く

The manual operation of Micro BCT Tester (2) Cylinder packages Place the package vertically, and mark as following: Mark the four points of the two diameters that are vertical 1, 3, 5,7. Mark the according 4 points on the bottom 2, 4, 6, 8. And 1-2, 3-4, 5-6, 7-8 is the mark of the four lines composed by points, which are parallel to the cylinder. If there is any seam, place one of the seam on the line marked 5-6, place others by the above order. 2. Test environment:

カタログの9ページ目を開く

The manual operation of Micro BCT Tester 3. Test steps A. Flat compression test A.1 Take the glove,check whether the power connect well. Press the power switch when check ok, the light will be on and the machine will start work. A.2 Press Up and Down and also can press high speed to increase the speed. Make sure that the machine stroke protection device is valid and adjust the interval between up pressure plate and below pressure plate according to the sample size; A.3 Place the sample on the central part of the below pressure plate according to normal transport state to make the up...

カタログの10ページ目を開く

The manual operation of Micro BCT Tester B. Compression test of edge and corner Add some load as initial load on the specimen before test, to make the specimen contact well with the upper and lower plates. Place the edge or the two cross corners at the centre of the machine when do the edge or corner test, add a initial load to make it fixed, and do the test as per A method. The maximum test strength together with the initial load is the maximum edge or corner compression strength. C. Cylinder package test method Make sure the specimen is in the centre and the seam is vertical to the...

カタログの11ページ目を開く

The manual operation of Micro BCT Tester D.5 Place the sample on the central part of the below pressure plate according to normal transport state to make the up pressure plate contact the sample; and make sure the screen display0.00 and then press test enter load test. D.7 When the force value reaches to stacking fixed value, the timer start to time automatically; when test time reaches to set time, the stacking test finishes. D.8 Press up and also press high speed to the position before the test. Press stop to increase the up speed to make the machine return and take out the sample to...

カタログの12ページ目を開くHAIDA EQUIPMENT CO.のすべてのカタログと技術パンフレット

-

WEPACK ASEAN 2024

1 ページ

-

How's your express?

4 ページ

-

Hardness Tester

2 ページ

-

How to select chairs

1 ページ

-

Salt Spray Chamber

5 ページ

-

Mid-Autumn Festival

2 ページ

-

IP ratings

2 ページ

-

Safety shoes

2 ページ

-

Battery test UN38.3

1 ページ

-

Optical instrument

2 ページ

-

Sock Test Machines

12 ページ

-

furniture testing

2 ページ

-

waterproof level

2 ページ

-

carton tester

7 ページ

-

Drop Tester

3 ページ

-

WHAT IS ISTA

2 ページ

-

Salt Spray Chamber

4 ページ

-

Zero Drop Tester

4 ページ

-

Battery Test

6 ページ

-

Lighting Test

1 ページ

-

Needle Detector 2022

1 ページ

-

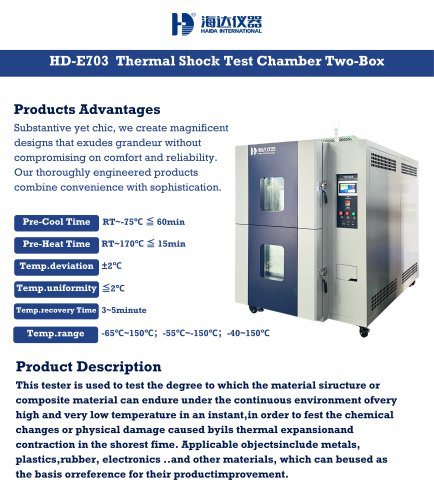

HD-E703

1 ページ

-

Tape Tester

1 ページ

-

History

1 ページ

-

Drop Test Machine

1 ページ

-

HD - A815

1 ページ

-

HD - A519

1 ページ

-

Dust Test Chamber

1 ページ

-

Chair Swivel Tester

1 ページ

-

Stroller Crash Test

1 ページ

-

HD-E808-60

1 ページ

-

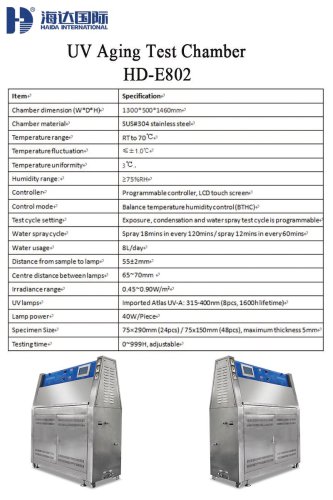

HD-E802

1 ページ

-

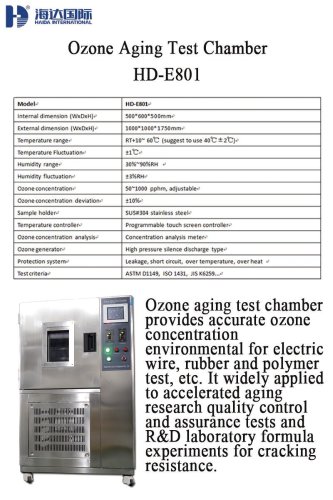

HD-E801

1 ページ

-

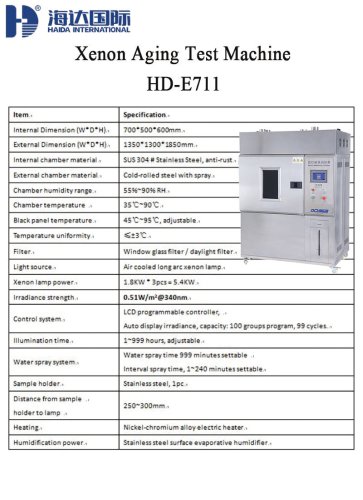

HD-E8711

1 ページ

-

HD-E710-4

1 ページ

-

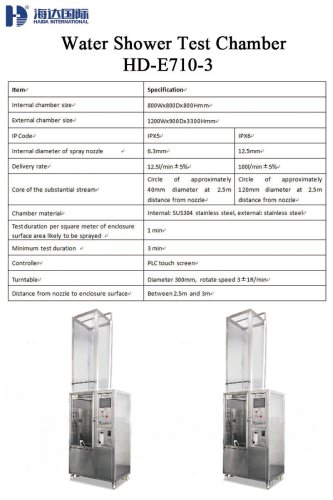

HD-E710-3

1 ページ

-

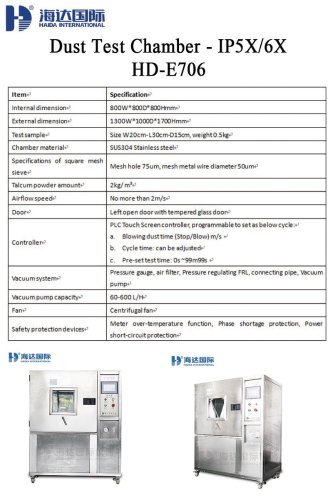

HD-E706

1 ページ

-

Chair Swivel Tester

1 ページ

-

HD-808-60

1 ページ

-

Walk-in Chamber

1 ページ

-

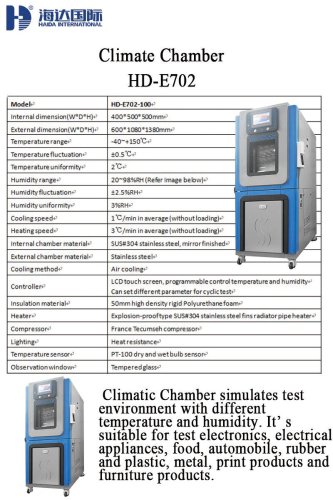

HD-E702

1 ページ

-

HD-E801

1 ページ

-

HD-E704

1 ページ

-

HD-B607-S

1 ページ

-

Peel Test Machine

1 ページ

-

HD -B609B-S

1 ページ

-

HD-B609

1 ページ

-

Eid al Adha

1 ページ

-

Visting Customers

1 ページ

-

Furniture Fair

1 ページ

-

DeliveBest Testing

1 ページ

-

Mattress Roll Tester

1 ページ

-

Tape testing machine

1 ページ

-

HD-E808-200

1 ページ

-

HAIDA EXHIBITION

1 ページ

-

Chair Swivel Tester

1 ページ

-

China.Shanghai.SNIEC

1 ページ

-

test equipement

1 ページ

-

ISTA Products

1 ページ

-

Tensile Test Machine

1 ページ

-

Water conseryation

1 ページ

-

ISTA MEMBER

1 ページ

-

Sofa Test Equipment

1 ページ

-

CLIMATE TEST CHAMBER

1 ページ

-

merry christmas

1 ページ

-

Thanksgiving Day

1 ページ

-

Chair Arm Tester

1 ページ

-

vacuum drying oven

1 ページ

-

Product Description

1 ページ

-

force test machine

1 ページ

-

Catalog

1 ページ

-

Tensile tester

1 ページ

-

ROHS test machine

4 ページ

-

HD-B615

1 ページ

-

HD-E702

1 ページ

-

HD-703

1 ページ

-

HD-E704

1 ページ

-

SPRAY RATE TESTER

3 ページ

-

BICYCLE TEST MACHINE

11 ページ

-

NEEDLE DETECTOR

2 ページ

-

HD-E702-150-7

4 ページ

-

ring test machine

9 ページ

-

Tensile Testing Machine

12 ページ

-

paper test machine

1 ページ

-

Gas chromatograph

1 ページ

-

coating machine

1 ページ

-

heat seal tester

1 ページ

-

zigzag spring tester

1 ページ

-

tensile tester

13 ページ

-

drying oven

1 ページ

カタログアーカイブ

-

Foam rebound tester

2 ページ

-

HD -B617S

1 ページ

-

HD -B617

1 ページ

-

HD-B615A- S

1 ページ

-

HD-B609B-S

1 ページ

-

HD-B609

1 ページ

-

HD-B617-S

1 ページ

-

HD -B617

1 ページ

-

HD-B616-S

1 ページ

-

HB-B616

1 ページ

-

HB-B615A-S

1 ページ

-

HB-B609D

1 ページ

-

HB-B609B-S

1 ページ

-

HB-B609A-S

1 ページ

-

HB-B609

1 ページ

-

HB-B607-S

1 ページ

-

HD -B604 -S

1 ページ

-

HB-B604B-S

1 ページ

-

HB-B602

1 ページ

-

HD-B601

1 ページ

-

Foam Fatigue Tester

1 ページ

-

HB-B617-S

1 ページ

-

HD -B617

1 ページ

-

HD-B616-S

1 ページ

-

HD-B615A-S

1 ページ

-

HD-B609A-S

1 ページ

-

HB-B604B-S

1 ページ

-

chair swivel tester

1 ページ