カタログの抜粋

EWELLIX MAKERS IN MOTION Fluid power replacement Solutions for Industry 4.0

カタログの1ページ目を開く

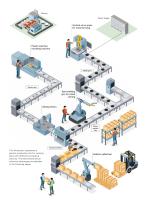

F l u i d P owe r R e p l a c e m e n t Factory Power Supply Vertical servo press for metal forming Plastic injection moulding machine Metal part Plastic part Spot welding gun for metal joining Gluing station Metal welded Part Glued assembly This illustration represents a generic production line for cooking pans with different processing stations. The electromechanical solutions advantages are detailed in the following pages. Robotic pallettizer

カタログの2ページ目を開く

Heritage of innovation for technology leadership Ewellix is a global innovator and manufacturer of linear motion and actuation solutions. Today, our state-of-the-art linear solutions are designed to increase machine performance, maximise uptime, reduce maintenance, improve safety and save energy. Technology leadership Global presence and local support Our journey began over 50 years ago as part of the SKF With our global presence, we are uniquely positioned to tise to continuously develop new technologies and use solutions, with full technical and applications support Group, and our history...

カタログの3ページ目を開く

Fluid Power Replacement Performance Focusing on linear motion technology, Ewellix is at the forefront of innovations supporting customers in the transition from established technologies for manufacturing processes into state of art solutions connected to Industry 4.0 principles. Possible Possible Predictive maintenance V S High High Contamination sensitivity Pneumatic Hydraulic Electromechanical

カタログの4ページ目を開く

gun for metal joining Gluing station Low gun weight Positioning precision Gluing station Positioning precision • Complete controllability • Higher positioning repeatability • Precise speed control • No warm up time Factory • Easier predictive maintenance operation • Less sensitive to contaminants, ensuring longer lifetime • Lower power consumption, optimized for the application Metal welded Part Power Supply Vertical servo press for Glued assembly metal forming High force and speed Robotic pallettizer High controlled speed Plastic injection moulding machine High force and positioning...

カタログの5ページ目を開く

Advantages Smaller installation space required in the machine Overall system is significantly Power density Pneumatic cylinder force capacity is heavily limited by the maximum pressure (usually up to 10 bars) that can be achieved and by the related energy losses due to the air compression. This means that to generate high forces, very big cylinder diameters and pressure levels are needed. And forces areusuallylimited to 30 kN for a size 200 cylinder. Electromechanical cylinders can always provide much higher forces compared to a pneumatic cylinder with the same sec-tion size, with a power...

カタログの6ページ目を開く

Performance overview Positioning precision Overall system weight Controlled speed Cylinder weight System complexity Installation space Cylinder dimension vs force Predictive maintenance Contamination sensitivity Power consumption High speed Pneumatic Positive Medium Negative

カタログの7ページ目を開く

Fluid Power Replacement EWELLIXEnvironment Performance optimization, easy integration and environmental friendliness are 3 key facts leading to total cost of ownership savings. Safety Hydraulic cylinders usually work with very high pressures (up to 350 bars) and represent a potential hazard for personnel working around the system, due to pinhole leaks and improper couplings. Moreover, if mineral oil is used, they can create a potential fire hazard. For pneumatics, the situation improves but the stored energy can still be a danger during maintenance checks or unexpected system shutdowns. It...

カタログの8ページ目を開く

Advantages • Safer during inspection and service • Safer during machine operation • Power consumption close to zero while not in use • Higher efficiency in converting electric into mechanical power Efficiency: Energy losses comparison Leakages 25% Mechanical 8% Output power 6% Output powe

カタログの9ページ目を開く

Advantages • Noise is generated only when operated • Noise level is usually negligible • Grease lubricant fully contained inside the actuator body • Very low heat generation Environmental Even though air is free, it can be contaminated by oil or other impurities, and needs to be filtered to avoid environmental pollution. Also, the leakages and disposal of hydraulic oil represent a significant environmental issue and a potential source of pollution. The energy losses on the whole system, especially on hydraulic, can cause ambient overheating that then has to be evacuated, causing extra...

カタログの10ページ目を開く

Environmental overview Potential hazard System noise level Cylinder noise level Heat generation Environmental pollution risk Pneumatic Positive Medium Negative

カタログの11ページ目を開く

Simplicity We are at a fourth era of history of manufacturing called Industry 4.0 where technologies and processes are connected in a collaborative network. Installation Pneumatic systems require many components, including hoses, pumps, valves, regulators, lubricators, and air filters. Hydraulic systems, as well, require a complex setup including a fluid reservoir, pumps, motors, release valves, heat exchangers, along with noise-reduction equipment. This means the commissioning time is also long since several parts of the system must be finetuned. Electromechanical systems only require a...

カタログの12ページ目を開く

Design When designing a fluid powered system, it’s important to correctly place the numerous components and to accurately define the right route for the pipes and hoses, creating constrains in the machine layout. Depending on the number of cylinders, the distance between them and the overall machine layout, the design phase can take some time as the designer also has to consider a simple installation and maintenance process. With electromechanical systems, the design process is lean thanks to few components and to the usage of electric cables only, that allow a more flexible routing and...

カタログの13ページ目を開く

Advantages • Virtually maintenance free • Easier implementation of predictive maintenance strategies • Easier and quicker cylinder replacement • No recalibration required after cylinder replacement Maintenance Fluid powered systems require constant maintenance to achieve overall system efficiency, avoiding leaks and failures. Filtering system, valves, pipes and fittings should be monitored and serviced to improve cylinder performance over time. Moreover, manual inspection operations are required to check the system status and spot possible issues. It’s also possible to perform predictive...

カタログの14ページ目を開くEWELLIXのすべてのカタログと技術パンフレット

-

LIFTKIT-OM

8 ページ

-

SLIDEKIT 2.0

12 ページ

-

LIFTKIT-0S

8 ページ

-

LIFTKIT-TM

8 ページ

-

Ball Screws

4 ページ

-

Roller screw catalogue

134 ページ

-

THG

6 ページ

-

Control units

26 ページ

-

Actuator range catalogue

310 ページ

-

Roller screws catalogue

134 ページ

-

SVC 8x1R 62/62 G3

3 ページ

-

CPMA

10 ページ

-

CPMB

10 ページ

-

LLU catalogue

74 ページ

-

Operating switches

28 ページ

-

CASM 100 - data sheet

38 ページ

-

Electric cylinders LEMC

48 ページ

-

Servo actuator SEMC

12 ページ

-

Servo pillar CPSM

10 ページ

-

ewellix brochure

5 ページ

-

Linear actuator CAMT

10 ページ

-

Electric cylinders CEMC

12 ページ