カタログの抜粋

POWERTRAIN SYSTEMS Delphi DP210 Rotary Mechanical Diesel Fuel Injection Pump The Delphi DP210 Rotary Mechanical Diesel Fuel Injection Pump is based on the Delphi DPA and DPS pumps, as well as the more advanced DP200 Series. It is a viable alternative to electronic control for diesel engine applications that must meet U.S. Tier II and equivalent emissions standards. The DP210 Injection Pump’s performance capability includes improved injection timing control, enhanced fuel/torque curve shaping, and improved pump-to-engine timing. The main components of the DP210 Injection Pump include: • • • • • • • • • • • Fuel inlet with inlet pressure variation and fuel viscosity compensation Transfer pump with pressure regulator Four-plunger pumping element with enhanced filling capability Distributor system with reduced high pressure volume Internal cam ring with scroll plate filling control Delphi DP210 Rotary Mechanical Diesel Injection timing control with increased light load advance Fuel Injection Pump travel Zero backlash drive shaft with increased shaft locking torque and improved timing accuracy Metering valve Mechanical all-speed governor Torque trimmer with excess fuel provision Electric shut-off Options include: • • • • • • • • • Clockwise or anti-clockwise drive Boost control for turbocharged engines Cold running injection timing control for operation at low engine coolant temperatures Mechanical generator set governing Electronic generator set governing conversion capability B20 and ultra low sulphur diesel compatible component package Adaptors for quick-fitting, low pressure connections Two-plunger design for low ratings and indirect injection (IDI) applications Timing overcheck feature www.delphi.com | © Delphi. All rights reserved. |

カタログの1ページ目を開く

Delphi DP210 Rotary Mechanical Diesel Fuel Injection Pump Benefits • Light load advance enhancements are designed to help meet U.S Tier II and equivalent emissions standards. Retarded full load injection timing reduces nitrous oxide (NOx) emissions, and light load advance travel capability to 28° engine maintains misfire margin at part load. The light load injection timing is set on each pump and the speed advance is controlled by a fixed stop at rated speed to provide advance consistency. The advance response rate is optimized to help prevent transient misfire. 3 Torque curve shaping...

カタログの2ページ目を開くDelphi Power Trainのすべてのカタログと技術パンフレット

-

Friction, Discs & Drums

1028 ページ

-

Turbochargers & DPF

114 ページ

-

Filtration & DPF

709 ページ

-

srs overview

12 ページ

-

Hybrid & Electric

8 ページ

カタログアーカイブ

-

E/E Architecture

8 ページ

-

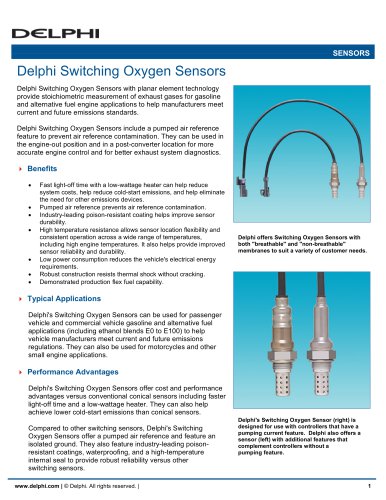

Sensors

12 ページ

-

Valve Train Systems

8 ページ

-

Ignition Systems

8 ページ

-

Exhaust Sensors

8 ページ