ウェブサイト:

Chotest Technology Inc.

ウェブサイト:

Chotest Technology Inc.

カタログの抜粋

Critical Dimension & Overlay Measurement System Patterned Wafer Critical Dimension & Overlay Measurement System BOKI_1000 Professional Inspection Equipment Overlay Offset Measurement During wafer manufacturing, the offset of the overlay after photoetching process is measured in Photo area, exposure of wafer, and compensation values based on the measurement are imported into the lithography machine to optimize the stability of the wafer photoetching process. Description Patterned Wafer Critical Dimension & Overlay Measurement System is an optical inspection instrument that can perform both high-precision XY plane dimension inspection and sub-nanometer surface 3D topography measurement. It can scan multiple regions on a large surface accurately and automatically with excellent repeatability, which significantly increases the measurement efficiency and reduces human error. Equipping high-resolution optical lens, combining high-precision image analysis algorithm, in CNC mode the system can automatically position & recognize the measuring objects, then automatically measure and evaluate all sizes according to program. At the same time, it integrates white light interferometry measurement system, which can scan the wafer surface to create a 3D profile image of Key Dimensions Measurement During wafer manufacturing, it requires to control critical dimensions of Die in multiple processes, and SuperView automatically extracts the feature edges of Die, and at the same time it measures all features according to program efficiently and accurately. the surface, then analyze Z-direction sizes in nanometer level. It is widely used in ultra-precision machining industries such as semiconductor manufacturing and packaging process inspection, optical processing, MEMS components, etc.

カタログの1ページ目を開く

Critical Dimension & Overlay Measurement System Patterned Wafer Critical Dimension & Overlay Measurement System BOKI_1000 Professional Inspection Equipment Overlay Offset Measurement During wafer manufacturing, the offset of the overlay after photoetching process is measured in Photo area, exposure of wafer, and compensation values based on the measurement are imported into the lithography machine to optimize the stability of the wafer photoetching process. Description Patterned Wafer Critical Dimension & Overlay Measurement System is an optical inspection instrument that can perform both...

カタログの2ページ目を開く

Professional Inspection Equipment Critical Dimension & Overlay Measurement System Critical Dimension & Overlay Measurement System 4 pcs of Cassette, size is customizable Feeding Sensor With anti-skid function Light Source White/Green LED (single or double is optional) Barcode Scanner Barcode recognition Video System Micro Objective Lens Interferometric Objective Lens 3D Dimensions Measurement During wafer manufacturing, it is necessary to measure the bottom width of the grooves to check whether the distance between dies is qualified after the previous process in Photo area. The software...

カタログの3ページ目を開く

Professional Inspection Equipment Critical Dimension & Overlay Measurement System Critical Dimension & Overlay Measurement System 4 pcs of Cassette, size is customizable Feeding Sensor With anti-skid function Light Source White/Green LED (single or double is optional) Barcode Scanner Barcode recognition Video System Micro Objective Lens Interferometric Objective Lens 3D Dimensions Measurement During wafer manufacturing, it is necessary to measure the bottom width of the grooves to check whether the distance between dies is qualified after the previous process in Photo area. The software...

カタログの4ページ目を開くChotest Technology Inc.のすべてのカタログと技術パンフレット

-

PRODUCT CATALOGUE

67 ページ

-

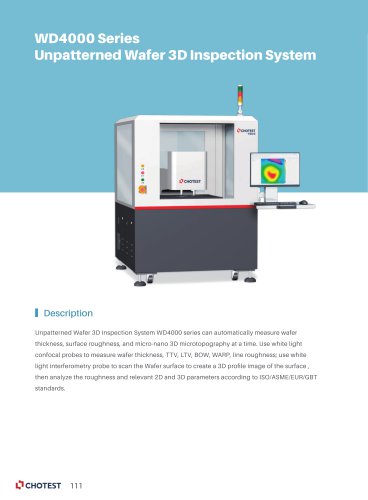

WD4000 SERIES

4 ページ

-

PO40 PO40L PO60

2 ページ

-

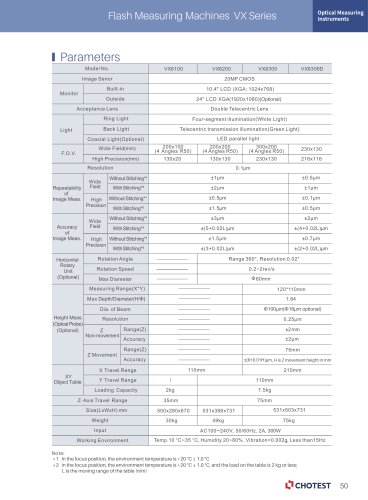

VX1060 VX1100

1 ページ