カタログの抜粋

High Precision Rack and Pinion

カタログの1ページ目を開く

Main Features High Precision High Loading High Speed Low Noise Long Life-Time Quick Delivery APEX is the ONLY ONE manufacturer worldwide who produces rack strictly according to specifications regarding : Geometrical Tolerance of all Dimensions Defined Straightness, Parallelism and Perpendicularity Helical Angle and Pressure Angle with Tolerance Defined Surface Roughness of Teeth Defined Hardness and Thickness of the Hardened Layer on the Teeth. APEX is also the ONLY ONE of the world leading brands who designs and produces rack, pinion and gearbox by its own, and provides well coordinated...

カタログの2ページ目を開く

Requirement of High-Precision Rack Page 3 Induction Hardening for Rack 13 Rack Quality and Application 15 Rack Order Code 16 Rack with Helical Teeth 17 Rack with Helical Teeth ( with Linear-Guide Interface, 90 Type ) 30 Rack with Helical Teeth ( with Linear-Guide Interface, 180 Type ) 31 APEX High Precision Pinion 32 APEX Pinion with Curvic Plate 33 Pinion Order Code 34 Pinion with Helical Teeth ( Curvic Plate / EN ISO 9409-1-A ) 35 Pinion with Helical Teeth ( Welded Plate / EN ISO 9409-1-A ) 40 Pinion with Helical Teeth ( Teeth Plate / EN ISO 9409-1-A ) 46 Pinion with Helical Teeth ( DIN...

カタログの3ページ目を開く

^ Pitch = n x Module No. ^ Total Pitch Error Et is to be measured between the first and the last tooth of a rack.

カタログの5ページ目を開く

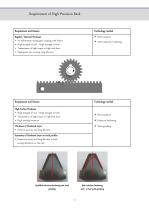

Bad induction hardening and / or bad teeth grinding Qualified induction hardening and teeth grinding

カタログの6ページ目を開く

APEX rack has been checked by Magnetic Crack Inspection Device!

カタログの7ページ目を開く

Quality Cross-Section * Straightness is given either in a free situation (Free) or on a certified flat surface in a fixed mounted situation (Fixed). By the Free-case, the rack is lying on the certified surface with its teeth at the side. Surface Roughness

カタログの8ページ目を開く

Tolerance of Rack Teeth APEX declares clearly all the tolerances of rack dimension and geometry, beginning from the design through out the manufacturing. Pressure Angle Deviation Height Deviation Angular Deviation Helical Angle Deviation H Length Deviation Angular Deviation Single Pitch Error Single Pitch Error Single Pitch Error Total Pitch Error Total Pitch Error Total Pitch The 1st Tooth Total Pitch Error Total Pitch

カタログの9ページ目を開く

For helical and straight teeth, basing on the nominal length 1000 mm. Straightness is to measure on a certified flat surface in a fix mounted situation.

カタログの10ページ目を開く

For helical and straight teeth, basing on the nominal length 1000 mm. Straightness is to measure on a certified flat surface in a fix mounted situation.

カタログの11ページ目を開く

For helical and straight teeth, basing on the nominal length 2000 mm. Straightness is to measure on a certified flat surface in a fix mounted situation.

カタログの12ページ目を開く

For helical and straight teeth, basing on the nominal length 2000 mm Straightness is to measure on a certified flat surface in a fix mounted situation.

カタログの13ページ目を開く

Scanning Induction Hardening T ooth-by-Tooth Induction Hardening Carburized Induction Hardening Induction Hardening Carburized Induction Hardening Note : In the cross-section, the effective thickness can be guaranteed over 80% in the middle of the teeth width.

カタログの14ページ目を開く

Material : Alloy Steel Heat-Treatment : Case Hardening Teeth : Ground

カタログの15ページ目を開く

Rack Order Code 06 100 Coating 0 = None N = Nickel Plating P = Phosphate Film B = Blackening Screw Holes 112 = Standard 0 = Without Screw Holes S / X = Strong Material C = Carbon Steel M = Alloy Steel S = Stainless Steel Q = Q&T Alloy Steel Teeth Angle R = Right-Hand Helical 19 31’42” 12 = Straight Module-No. 1 ~ 12 The non-integer module no. will be given in alphabet. 2 A1 = For Linear-Guide Interface, 90 Type A2 = For Linear-Guide Interface, 180 Type

カタログの17ページ目を開く

Quality 4 / Carbon Steel Tooth Thickness Tolerance : -13 ~ 0 |4m Right-Hand Helical Teeth Teeth Induction Hardened and Ground All Sides Ground (1) Teeth Pitch Pt = Module x n / cos (19 31’42” ) (2) fp —Single Pitch Error (3) Fp— Total Pitch Error * For all models APEX also provides Rack without screw-holes. By ordering please change the 2nd last order-code position from “1” to “0”. Please also refer to page 14.

カタログの18ページ目を開く

Quality 5H / Alloy Steel Tooth Thickness Tolerance : -15 ~ 0 |Tm Right-Hand Helical Teeth Material Case-Hardened Teeth Ground and all Sides Ground (1) Teeth Pitch Pt = Module x n / cos (19 31’42” ) (2) fp —Single Pitch Error (3) Fp — Total Pitch Error * For all models APEX also provides Rack without screw-holes. By ordering please change the 2nd last order-code position from “1” to “0”. Please also refer to page 14. Especially for the application without back-support. With alignment / back-support

カタログの19ページ目を開く

Quality 5 / Alloy Steel Tooth Thickness Tolerance : -15 ~ 0 |dm Right-Hand Helical Teeth Material Carburized, Induction Hardened Teeth Ground and all Sides Ground (1) Teeth Pitch Pt = Module x n / cos (19 3l’42” ) (2) fp —Single Pitch Error (3) Fp — Total Pitch Error For all models APEX also provides Rack without screw-holes. By ordering please change the 2nd last order-code position from “1” to “0”. Please also refer to page 14.

カタログの20ページ目を開く

Quality 5 / Carbon Steel Tooth Thickness Tolerance : -15 ~ 0 |Tm Right-Hand Helical Teeth Teeth Induction Hardened and Ground All Sides Ground (1) Teeth Pitch Pt = Module x n / cos (19 31’42” ) (2) fp —Single Pitch Error (3) Fp — Total Pitch Error For all models APEX also provides Rack without screw-holes. By ordering please change the 2nd last order-code position from “1” to “0”. Please also refer to page 14.

カタログの21ページ目を開く

Quality 5+ / Carbon Steel Tooth Thickness Tolerance : -15 ~ 0 |Tm Right-Hand Helical Teeth Teeth Induction Hardened and Ground All Sides Ground (1) Teeth Pitch Pt = Module x TC / cos (19 31’42” ) (2) fp —Single Pitch Error (3) Fp — Total Pitch Error

カタログの22ページ目を開く

Quality 6 / Carbon Steel Tooth Thickness Tolerance : -22 ~ 0 |Am Right-Hand Helical Teeth Teeth Induction Hardened and Ground All Sides Ground (1) Teeth Pitch Pt = Module x n / cos (19 3l’42” ) (2) fp —Single Pitch Error (3) Fp — Total Pitch Error For all models APEX also provides Rack without screw-holes. By ordering please change the 2nd last order-code position from “1” to “0”. Please also refer to page 14.

カタログの23ページ目を開くApex Dynamicsのすべてのカタログと技術パンフレット

-

PII&PIIR series

36 ページ

-

GL / GLS - SERIES

10 ページ

-

AFX/AFXR series

14 ページ

-

AD/ADR/ADS series

18 ページ

-

KH/KFSeries

20 ページ

-

AT / ATB Series

28 ページ

-

SMART LUBRICATION SYSTEM

24 ページ

-

SH SERIES

2 ページ

-

SC SERIES

6 ページ

-

Power Tool Turret

16 ページ

-

AH / AHK Series

20 ページ

-

PSII series

20 ページ

-

PEII series

20 ページ

-

PAII series

20 ページ

-

PGII series

20 ページ