カタログの抜粋

Laser Cutting System The Sigma XY laser cutting system offers high speed, precision laser cutting of thin metals using a highly rigid linear drive gantry based motion system. The motion and laser are fully integrated to enable optimal tooling path accuracy and laser parameter control for cut speed and quality. • Precision cutting of thin metals • Fiber laser technology • Fully integrated fiber laser controller • Granite mounted gantry, high strength welded base KEY FEATURES • Precision cutting of thin metals – highly accurate linear motors, combined with the fine spot capability of a fiber laser enables high dimensional accuracy on cutting profiles. Proprietary laser power ramping algorithm for acceleration and deceleration profiles provides fast cut times. • Fiber laser technology – fiber lasers offers high resolution cutting with spot sizes down to 10 microns, and high speed cutting through high repetition rates. Up to 500 W of laser power available to address a wide range of materials including steels, aluminum and copper. TYPICAL APPLICATIONS Metal laminates • Fully integrated laser control – successful optimized cutting requires complete control and integration of the laser. Amada Miyachi's fiber laser controller enables pulse widths to 10 microseconds, pulse frequency up to 50 kHz, and precise control of the power. • Highly rigid system – high mechanical stiffness is necessary to accommodate the high acceleration and deceleration rates needed to minimize cycle times. The Sigma XY system incorporates a 4 inch thick granite base, secured to a high strength welded steel base, to ensure system rigidity. • Options – Class 1 or Class 4 operation, cutting box style, fume exhaust, part hold down tooling, focus control sensing, programmable gas pressure, high pressure cutting heads, 4 or 8 inch travel z stage axes motion and a control pendant. Electronic device mounting plate Medical electrodes

カタログの1ページ目を開く

TECHNICAL SPECIFICATIONS MOTION Total travel Maximum linear acceleration LASER Laser power Beam quality Pulse width control Minimum pulse increment Operating temperature range SYSTEM REQUIREMENTS Power WEIGHT & DIMENSIONS Dimensions (L x W x H) 1820 S. Myrtle Ave. • Monrovia, CA 91016 US T: (626) 303-5676 • F: (626) 358-8048 info@amadamiyachi.com • www.amadamiyachi.com ISO 9001 Certified Company • 24/7 Repair Service: 1-866-751-7378 Amada Miyachi America Mexico El Paso, TX 79925 T: (915) 881-8765 mxsales@amadamiyachi.com Amada Miyachi do Brasil Ltda. Sao Paulo, Brasil T: +55-11-4193-3607...

カタログの2ページ目を開くAMADA WELD TECH Inc.のすべてのカタログと技術パンフレット

-

TC-W100A

2 ページ

-

MEA-100B

2 ページ

-

MIB-300A/600A

2 ページ

-

AMADA WELD TECH

24 ページ

-

HF-2700A / HF-2500A

4 ページ

-

CD-V Series

2 ページ

-

ISQ Series

3 ページ

-

IPB-5000A-MU

2 ページ

-

MFP60 for aws3

2 ページ

-

MFP25 FRO AWS3

2 ページ

-

Series 320

2 ページ

-

newhorizon

3 ページ

-

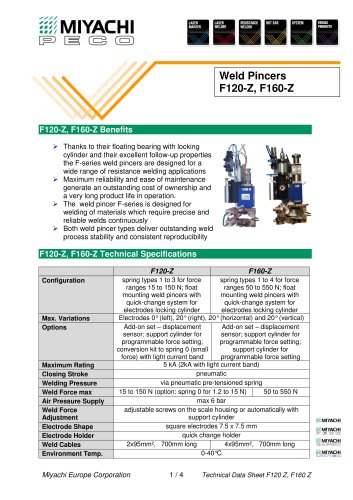

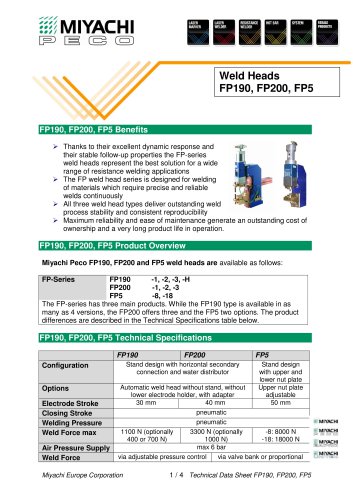

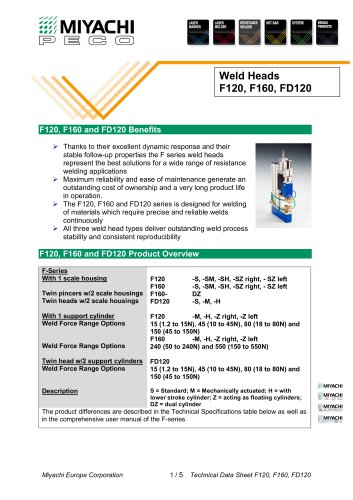

F120, F160, FD120

4 ページ

-

KN-II Series

2 ページ

-

MH Weld Head Range

4 ページ

-

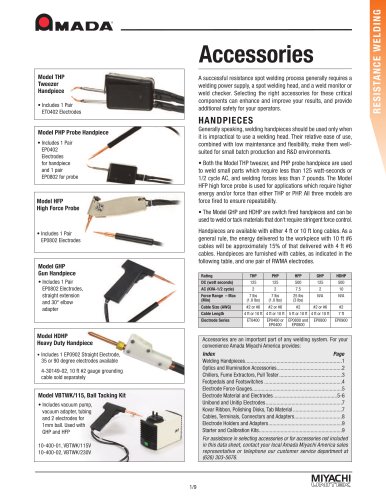

Accessries

9 ページ

-

ML-5120A

2 ページ

-

Systems

16 ページ

-

ML-5120

2 ページ

-

DC29-UB29-UB29A

4 ページ

-

LF Series Lasers

2 ページ

-

SA2200 Dual Oven

2 ページ

-

Heat Staking

2 ページ

-

Systems Datasheet

16 ページ

-

AX5000 Glovebox

2 ページ

-

MX2000 Glovebox

2 ページ

-

Pulsed-Heat Hot-Bar

10 ページ

-

Benchmark SM8500

2 ページ

-

vacuum bakeout oven

2 ページ

-

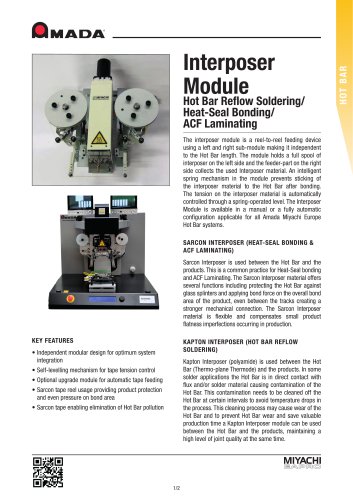

Interposer Module

2 ページ

-

Laser Marker Motion

2 ページ

-

Laser Accessories

7 ページ

-

Alpha Series

2 ページ

-

AX-5000 Glovebox

2 ページ

-

Thin Line Weld Heads

8 ページ

-

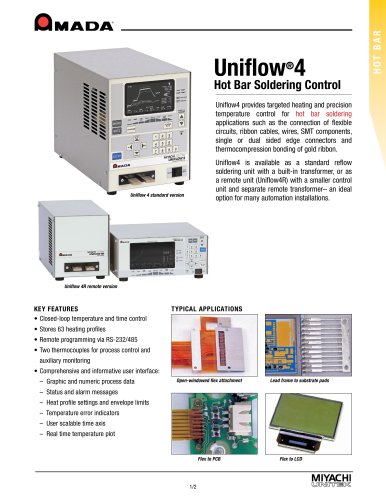

Uniflow 4

2 ページ

-

Pulsar

2 ページ

-

LW300-600A

2 ページ

-

LW50A-70-150A

2 ページ

-

LW5-15-25A

2 ページ

-

LF Series

2 ページ

-

50 Series Weld Heads

4 ページ

-

MH Series Weld Heads

4 ページ

-

MG3

12 ページ

-

Thin-line

8 ページ

-

IS series

2 ページ

-

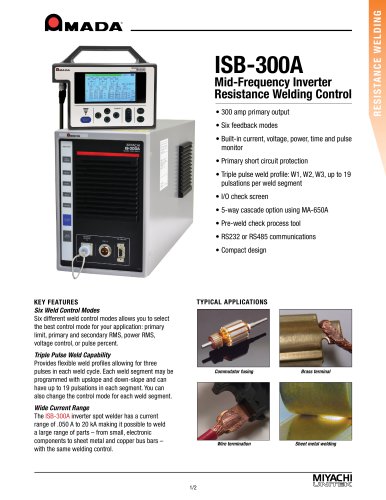

ISB-300 A

2 ページ

-

Accessoires

9 ページ

-

DC25, UB25

4 ページ

-

Bonding Heads

2 ページ