カタログの抜粋

TRANSISTOR WELDING POWER SUPPLIES MDA-10000A/MDB-5000A Transistor-controlled welding power supply Short-time, Large-current Welding by Multiple Connection of Power Supplies [ Current rise of transistor-controlled welding power supply is faster than others. ] Weld current Capacitor discharge DC inverter MDB-5000A (Left: Slave unit / Right: Master unit) Welding time Features ■ Multiple connection of power supplies realizes high power welding at short time. MDA-10000A: Maximum twelve units connectable (One master and eleven slave units). Design your own system to add power supplies as much as you need to obtain enough power. ■ One master unit controls all connected units. It does not necessary to set the weld schedule at each unit anymore. A master unit is an only unit to need to be set and controls all slave units. ■ All units' current feedback. The current feedback feature controls to stabilize current collectively from all connected units. ■ Polarity switchable type: MDB-5000A Alternate current flow from plus and minus side reduces Peltier effect and shapes nuggets uniformly. Best suited for series welding applications. ■ Three control types to choose from. Both MDA-10000A and MDB-5000A employ the following three types of control: Constant current In the intial phase of welding Constant voltage & control works and supports welding without weld Constant voltage splash. Then, Constant current control works to keep current constant and supports stable welding. Constant Voltage Stabilize voltage from the beginning of the welding The timing when Constant current control starts to process and suppress current. Reduce weld splash. work can be set up. Constant Current Apply constant current to a workpiece regardless of the resistance of it. Ensure stable welding. Optical sensor parts Crystal oscillators Projection welding of electronic parts

カタログの1ページ目を開く

TRANSISTOR WELDING POWER SUPPLIES MDA-10000A / MDB-5000A Transistor-controlled Welding Power Supply External views MDA-10000A / MDB-5000A * The values in parenthesis are of a slave unit. POWER OVER CU RR CURR OVER HE AT HEAT OVER CH AR CHAR WELD STA WE READY RE MODEL Type Power requirements Power consumption Feedback mode Number of connectable unit Time setting (31 schedules) Maximum current Maximum voltage Squeeze time Pre-weld check Pre-weld check Upslope Weld 1 / Weld 1&2 Cool time Downslope Hold time Monitor display Standard Polarity switchable Single phase, 100 - 120VAC or 200 -...

カタログの2ページ目を開くAMADA WELD TECH Inc.のすべてのカタログと技術パンフレット

-

TC-W100A

2 ページ

-

MEA-100B

2 ページ

-

MIB-300A/600A

2 ページ

-

AMADA WELD TECH

24 ページ

-

HF-2700A / HF-2500A

4 ページ

-

CD-V Series

2 ページ

-

ISQ Series

3 ページ

-

IPB-5000A-MU

2 ページ

-

MFP60 for aws3

2 ページ

-

MFP25 FRO AWS3

2 ページ

-

Series 320

2 ページ

-

newhorizon

3 ページ

-

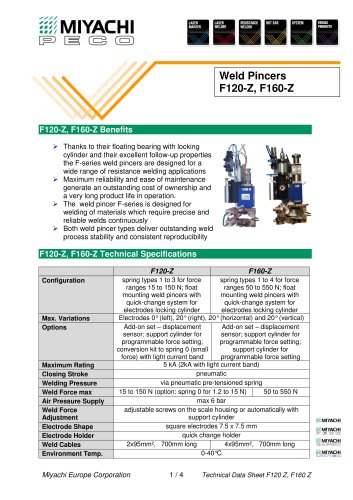

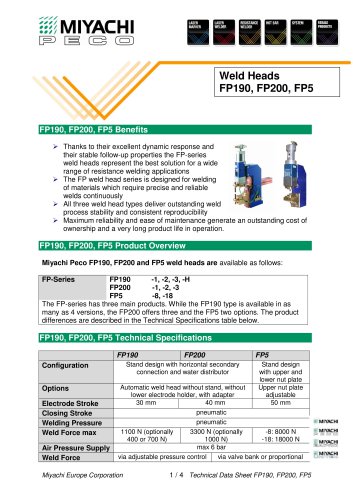

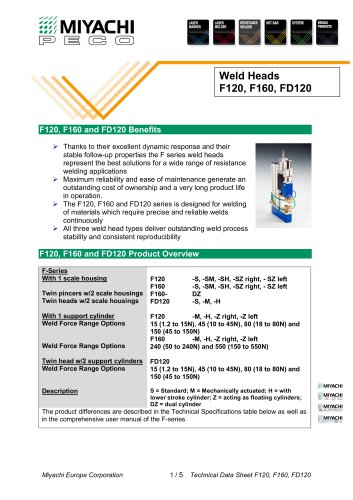

F120, F160, FD120

4 ページ

-

KN-II Series

2 ページ

-

MH Weld Head Range

4 ページ

-

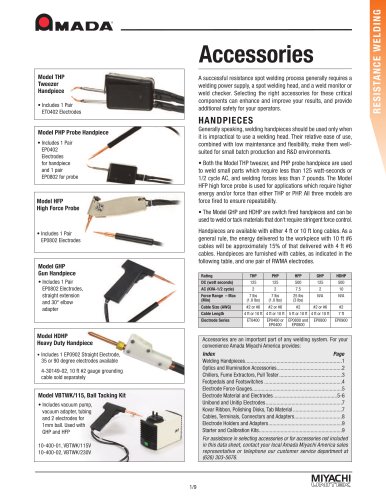

Accessries

9 ページ

-

ML-5120A

2 ページ

-

Systems

16 ページ

-

ML-5120

2 ページ

-

DC29-UB29-UB29A

4 ページ

-

LF Series Lasers

2 ページ

-

SA2200 Dual Oven

2 ページ

-

Heat Staking

2 ページ

-

Systems Datasheet

16 ページ

-

AX5000 Glovebox

2 ページ

-

MX2000 Glovebox

2 ページ

-

Pulsed-Heat Hot-Bar

10 ページ

-

Benchmark SM8500

2 ページ

-

vacuum bakeout oven

2 ページ

-

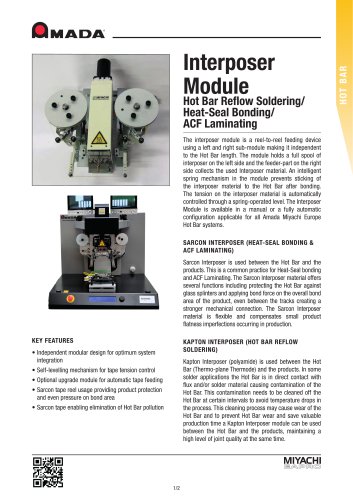

Interposer Module

2 ページ

-

Laser Marker Motion

2 ページ

-

Laser Accessories

7 ページ

-

Alpha Series

2 ページ

-

AX-5000 Glovebox

2 ページ

-

Thin Line Weld Heads

8 ページ

-

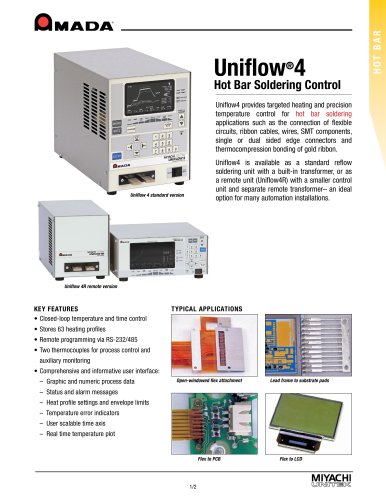

Uniflow 4

2 ページ

-

Pulsar

2 ページ

-

LW300-600A

2 ページ

-

LW50A-70-150A

2 ページ

-

LW5-15-25A

2 ページ

-

LF Series

2 ページ

-

50 Series Weld Heads

4 ページ

-

MH Series Weld Heads

4 ページ

-

MG3

12 ページ

-

Thin-line

8 ページ

-

IS series

2 ページ

-

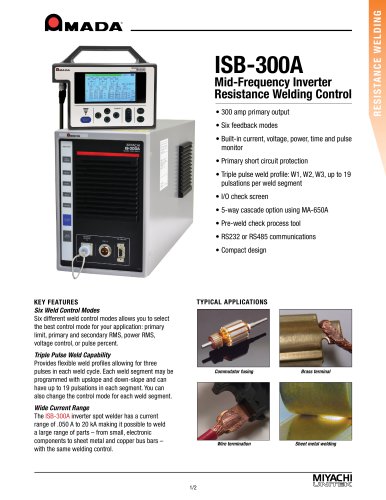

ISB-300 A

2 ページ

-

Accessoires

9 ページ

-

DC25, UB25

4 ページ

-

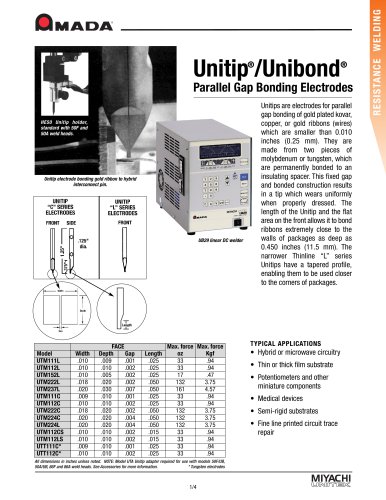

Bonding Heads

2 ページ