カタログの抜粋

Single Phase AC Spot Weld Control The STA-Series welders are the most advanced, yet simplest welding controls on the market. They feature an intuitive, easy-to-use programming interface and is designed to control and integrate projection welders, press welders, multi-gun machines, portable guns, seam welders, robotic systems, rocker arm welders and special purpose machines. KEY FEATURES • Primary and secondary constant current – provide closed-loop feedback and deliver superior control and improved welding results. • Built-in weld monitoring – the control will monitor the delivered RMS current for the weld period and conduction angle. Limits can be set and alarms generated if out of limits. • Dual Pulse with programmable upslope/downslope – upslope and downslope can be programmed for both Weld 1 and 2 to accurately control the heating rates of the materials and provide success with difficult welding combinations. • Voltage monitoring option card – when welding in constant current the RMS voltage can be monitored to provide a useful quality indicator. • Current stepping – a versatile stepping function allows the current to step automatically to compensate for electrode wear and ensure consistent welds. • Electronic pressure regulator and differential pressure monitoring option – force can be set electronically as part of the weld schedule, limits can be set on actual firing force. • Simple, intuitive programming – large LCD, logical software and push button layout allows easy programming and viewing of weld schedule information. • Spot, seam and roll spot capability • Communication option TYPICAL APPLICATIONS Automotive assembly 10 gauge wiring harness assembly Motor fusing RESISTANCE WELDING

カタログの1ページ目を開く

SECONDARY VOLTAGE MONITORING OPTION When welding in Constant Current mode the current is held constant during the weld by the STA control algorithms. Monitoring the secondary voltage can provide useful quality indicators, as voltage changes can be associated with resistance changes during the weld. Pre-Weld Check - The STA control allows the user to program a low energy current welding pulse prior to the main welding pulse. The voltage during this first pulse can be monitored and limits applied. As the current is constant the voltage represents the resistance during the check pulse. Limits...

カタログの2ページ目を開く

Operation Modes • Percent heat – allows programming of the percent of each half cycle during the individual weld periods in 1% increments. The control software will automatically scale output percentages over the number of cycles for up and downslope. • Primary constant current RMS – acquires feedback from an internal primary coil and therefore requires no secondary coil. Useful for robotics, programs in RMS values. Current can be set in kA. The control software will scale output for up and downslope. • Secondary constant current – acquires feedback from a secondary coil. Most accurate...

カタログの3ページ目を開く

DESIGNED FOR RELIABILITY & PERFORMANCE The STA Series is designed to perform in the harshest of environments. Inside the NEMA style cabinet, the power supply is logically laid out in a modular fashion and manufactured to the highest quality standards. Key • Accessory Mounting - space has been allowed in the design to accommodate PLC controls and ancillary devices for automation • I/O - All I/O is labeled and located on removable terminal strips. • Robustness - Amada Miyachi's products are well respected within all types of manufacturing industries for their durability and robust performance...

カタログの4ページ目を開く

STEPPER FUNCTIONS The STA Series controls have sophisticated steppers for varying the heat delivered to the weld over multiple welding sequences. Users who are familiar with their electrode wear and oxidation cycles are able to further increase the time between routine electrode maintenance by taking advantage of the advanced stepping functions. The STA is able to execute up to nine steps in a single sequence with user programmable step counts. Steps can be a fixed percentage heat increase or decrease after a certain number of welds. Step routines can be programmed directly using the STAs...

カタログの5ページ目を開く

RESISTANCE WELDING TECHNICAL SPECIFICATIONS Power source Control method Weld schedules Time settings Heat settings Current monitor Conduction degree monitor Current steppers Valve outputs Modes STA Series 201 to 270 VAC or 402 to 540 VAC, 50/60 Hz, single phase AVC 64 Squeeze delay 0 - 99 cycles Squeeze 0 - 99 cycles Upslope 1, 2 0 - 99 cycles Weld 1, 2 0 - 99 cycles Downslope 1, 2 0 - 99 cycles Cool 0 - 99 cycles Hold, Off 0 - 99 cycles Impulses 25 Heat 1 80 kA Heat 2 80 kA High limit 100 - 150%, low limit 50 - 100% 0 to 180° 1 stepper per valve 4 standard valve driver outputs Chaining,...

カタログの6ページ目を開くAMADA WELD TECH Inc.のすべてのカタログと技術パンフレット

-

TC-W100A

2 ページ

-

MEA-100B

2 ページ

-

MIB-300A/600A

2 ページ

-

AMADA WELD TECH

24 ページ

-

HF-2700A / HF-2500A

4 ページ

-

CD-V Series

2 ページ

-

ISQ Series

3 ページ

-

IPB-5000A-MU

2 ページ

-

MFP60 for aws3

2 ページ

-

MFP25 FRO AWS3

2 ページ

-

Series 320

2 ページ

-

newhorizon

3 ページ

-

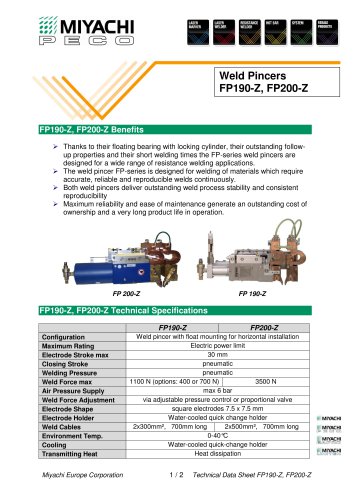

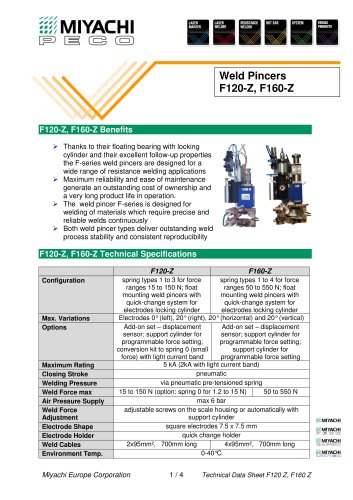

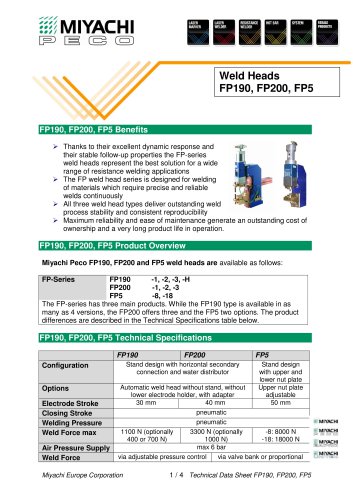

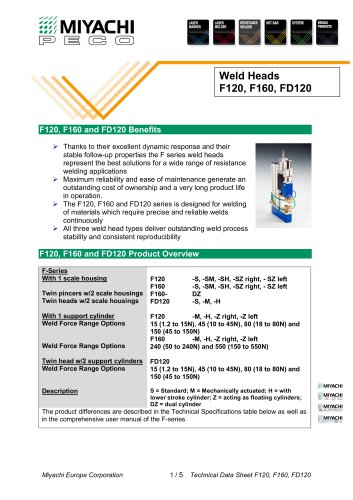

F120, F160, FD120

4 ページ

-

KN-II Series

2 ページ

-

MH Weld Head Range

4 ページ

-

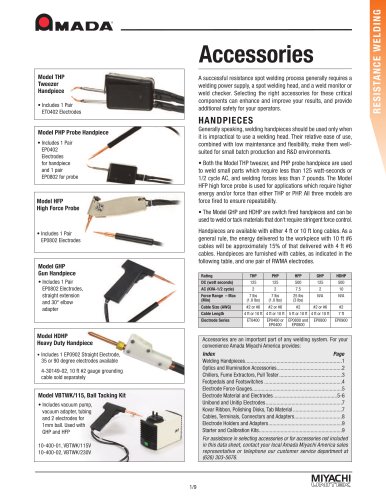

Accessries

9 ページ

-

ML-5120A

2 ページ

-

Systems

16 ページ

-

ML-5120

2 ページ

-

DC29-UB29-UB29A

4 ページ

-

LF Series Lasers

2 ページ

-

SA2200 Dual Oven

2 ページ

-

Heat Staking

2 ページ

-

Systems Datasheet

16 ページ

-

AX5000 Glovebox

2 ページ

-

MX2000 Glovebox

2 ページ

-

Pulsed-Heat Hot-Bar

10 ページ

-

Benchmark SM8500

2 ページ

-

vacuum bakeout oven

2 ページ

-

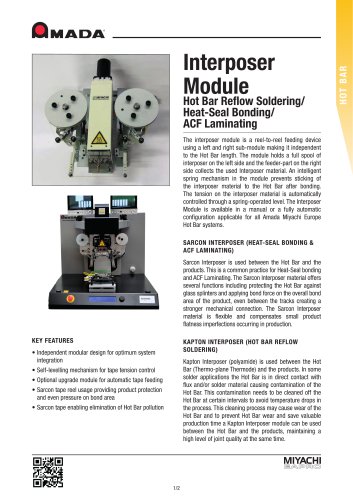

Interposer Module

2 ページ

-

Laser Marker Motion

2 ページ

-

Laser Accessories

7 ページ

-

Alpha Series

2 ページ

-

AX-5000 Glovebox

2 ページ

-

Thin Line Weld Heads

8 ページ

-

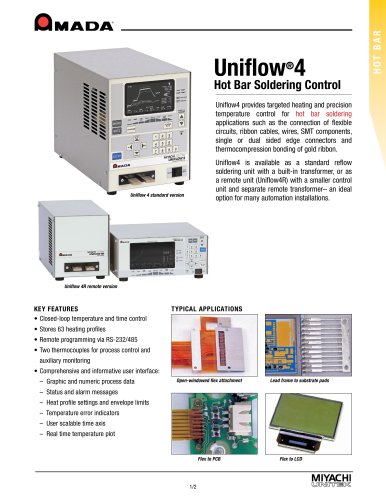

Uniflow 4

2 ページ

-

Pulsar

2 ページ

-

LW300-600A

2 ページ

-

LW50A-70-150A

2 ページ

-

LW5-15-25A

2 ページ

-

LF Series

2 ページ

-

50 Series Weld Heads

4 ページ

-

MH Series Weld Heads

4 ページ

-

MG3

12 ページ

-

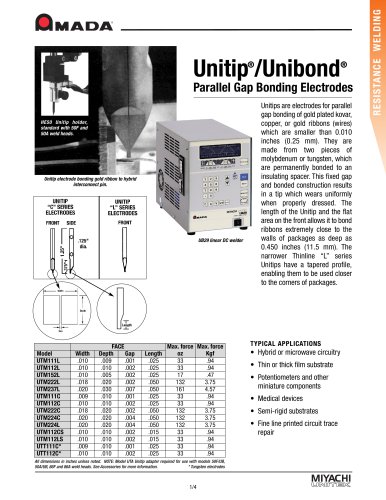

Thin-line

8 ページ

-

IS series

2 ページ

-

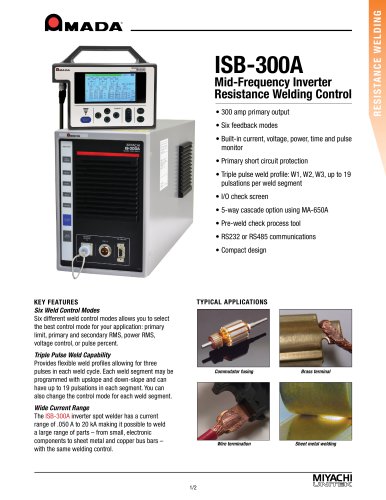

ISB-300 A

2 ページ

-

Accessoires

9 ページ

-

DC25, UB25

4 ページ

-

Bonding Heads

2 ページ