カタログの抜粋

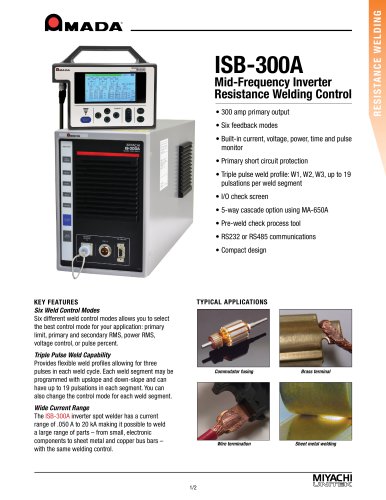

Mid-Frequency Inverter Resistance Welding Control • 800 or 1400 amp primary output resistance weld control • Six feedback modes • Built-in current, voltage, power, time and pulse monitor • Optional displacement monitoring and proportional regulator control • Primary short circuit protection • Triple pulse weld profile: W1, W2, W3, up to 19 pulsations per weld segment • Pre-weld check process tool • I/O check screen • Cascade option: 5 and 7 way cascade • RS232 or RS485 communications • NEMA style enclosures KEY FEATURES Six Weld Control Modes Six different weld control modes allow the user to select the best mode for the application: primary limit, primary and secondary RMS, power RMS, voltage control, or pulse percent TYPICAL APPLICATIONS Triple Pulse Weld Capability Provides flexible weld profiles with up to three pulses in each weld cycle. Each weld segment can be programmed with upslope and downslope and may have up to 19 pulsations per segment. Users may change the control mode for each weld segment. Wide Current Range Commutator fusing Wire termination Sheet metal welding Braided cable termination IS-800CR has a current range of .050 A to 40 kA; and IS-1400CR has a range of .050 A to 80 kA making it possible to weld a large range of parts – from small, electronic components to sheet metal and copper bus bars – with the same welding control Optional Displacement Limits & Force Monitoring Dial-in the weld process by utilizing the IS Series’ displacement and force features including initial part thickness, weld-displacement, and final displacement limits. Monitor the force of each segment of the weld pulse RESISTANCE WELDING

カタログの1ページ目を開く

RESISTANCE WELDING Maximum primary output current (peak) Settings – Constant current – Constant power – Constant voltage – Fixed pulse Weld monitors – Current – Power – Voltage – Pulse % Power source Output frequency Control modes Number of schedules Time settings Squeeze delay Squeeze Upslope 1, 2, 3 Weld 1, 2, 3 Cool 1, 2 Down slope 1 ,2, 3 Hold Off time Pulsation setting Transformer turns ratio Valve setting Control gain (GAIN) Step-up/-down (STEPPER COUNT) Weld count monitor (PRESET COUNT) External communication Program protect WEIGHT & DIMENSIONS Dimensions L x W x H Weight Options...

カタログの2ページ目を開くAMADA WELD TECH Inc.のすべてのカタログと技術パンフレット

-

TC-W100A

2 ページ

-

MEA-100B

2 ページ

-

MIB-300A/600A

2 ページ

-

AMADA WELD TECH

24 ページ

-

HF-2700A / HF-2500A

4 ページ

-

CD-V Series

2 ページ

-

ISQ Series

3 ページ

-

IPB-5000A-MU

2 ページ

-

MFP60 for aws3

2 ページ

-

MFP25 FRO AWS3

2 ページ

-

Series 320

2 ページ

-

newhorizon

3 ページ

-

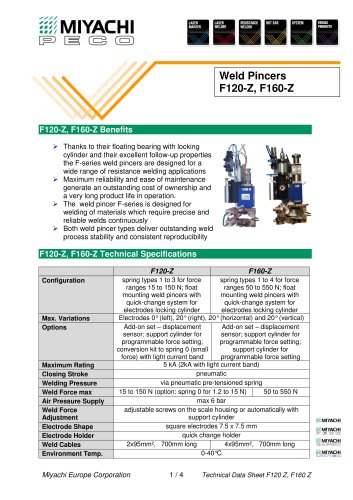

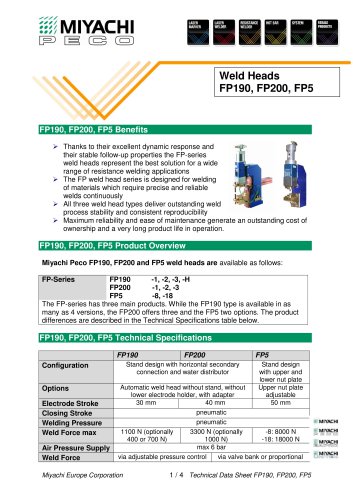

F120, F160, FD120

4 ページ

-

KN-II Series

2 ページ

-

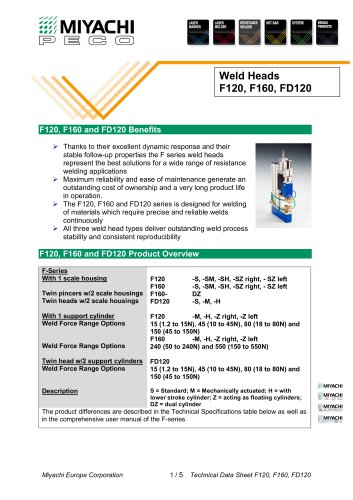

MH Weld Head Range

4 ページ

-

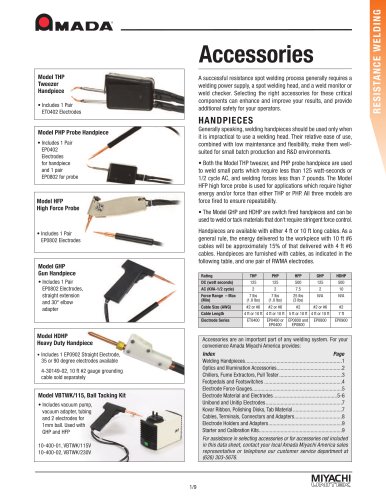

Accessries

9 ページ

-

ML-5120A

2 ページ

-

Systems

16 ページ

-

ML-5120

2 ページ

-

DC29-UB29-UB29A

4 ページ

-

LF Series Lasers

2 ページ

-

SA2200 Dual Oven

2 ページ

-

Heat Staking

2 ページ

-

Systems Datasheet

16 ページ

-

AX5000 Glovebox

2 ページ

-

MX2000 Glovebox

2 ページ

-

Pulsed-Heat Hot-Bar

10 ページ

-

Benchmark SM8500

2 ページ

-

vacuum bakeout oven

2 ページ

-

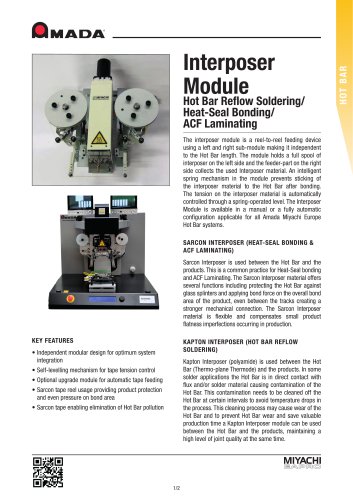

Interposer Module

2 ページ

-

Laser Marker Motion

2 ページ

-

Laser Accessories

7 ページ

-

Alpha Series

2 ページ

-

AX-5000 Glovebox

2 ページ

-

Thin Line Weld Heads

8 ページ

-

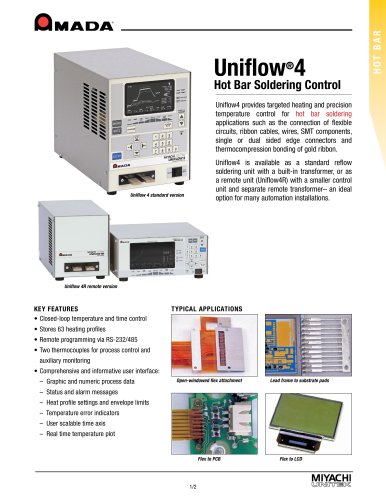

Uniflow 4

2 ページ

-

Pulsar

2 ページ

-

LW300-600A

2 ページ

-

LW50A-70-150A

2 ページ

-

LW5-15-25A

2 ページ

-

LF Series

2 ページ

-

50 Series Weld Heads

4 ページ

-

MH Series Weld Heads

4 ページ

-

MG3

12 ページ

-

Thin-line

8 ページ

-

ISB-300 A

2 ページ

-

Accessoires

9 ページ

-

DC25, UB25

4 ページ

-

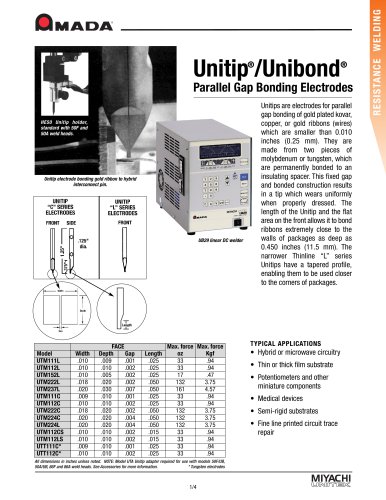

Bonding Heads

2 ページ