カタログの抜粋

High Frequency Welding Control HIGH RELIABILITY MICROJOINING The HF Series high frequency weld controls address the challenges of micro welding for a wide range of applications. Precise control of weld energy with high speed closed loop feedback and weld quality tools ensure high yields for the most demanding welding applications. HF series weld controls are also geared for automation featuring exceptional repetition rates, standard I/O connections and remote programming capability. KEY FEATURES CONTROL FEATURES: • Constant current, voltage, and power modes TYPICAL APPLICATIONS • Monitors energy and resistance • 2400 A maximum • 25 kHz feedback WELD QUALITY PROCESS TOOLS: • Active Part Conditioning (APC) Anti-lock brake system solenoid Critical parts fabrication Switch assembly Implantable device interconnects • Pre-Weld Check • Weld to Limits HF27 ADVANCED FEATURES: • Displacement and force monitoring • Force control • Envelope function • Combo mode • Energy and time limits RESISTANCE WELDING

カタログの1ページ目を開く

CURRENT, VOLTAGE AND POWER FEEDBACK MODES: INTUITIVE, EASY-TO-USE • Intuitive graphical user interface. • Dual pulse waveforms programmed in current, voltage, or power control modes. • Programming times to 100 usee increments provides ultimate control. • Accurate, built-in monitor displays the graphical "trace" of weld current, voltage, power and resistance, along with numerical peak and average values. • Easy-to-set limits establish process window • User programmable relays can be used in conjunction with visual and audible signals for operators and automation interface. • Compensates for...

カタログの2ページ目を開く

Part Displacement Thickness Measurement ft}ij;|^iHHj edit, IMil Run ADVANCED PROCESS FEATURES HF27 Precisely Controls and Monitors Electrical and Mechanical Weld Parameters • Initial thickness (part detection) • Final thickness • Weld displacement (set down) • Energy stop (weld to limit) Measurement of initial part thickness can confirm parts are present and aligned for welding. Settings limits on confirm the electrical parameters have produced the correct part displacement and can also prove a good indication of weld quality. Final Part LVDT screen - program limits and view results...

カタログの3ページ目を開く

RESISTANCE WELDING TECHNICAL SPECIFICATIONS Model Number HF25/240 HF25/400 HF25/480 HF27/240 HF27/400 HF27/480 Nominal line voltage (3 phase) 240 VAC 400 VAC 480 VAC 240 VAC 400 VAC 480 VAC Line voltage range (VAC) 192 to 264 320 to 440 384 to 528 192 to 264 320 to 440 384 to 528 Input circuit rating (per phase) 25 A 20 A 13 A 25 A 20 A 13 A Input KVA @ 3% duty cycle 30 KVA Output KW @ max. demand 12 KW Output transformer voltage @ max. rated output current 5.2 V Open circuit max. output voltage @ nominal line 11.5 V Setting ranges Current – 100 A to 2400 A; Voltage – 0.2 V to 10 V; Power –...

カタログの4ページ目を開くAMADA WELD TECH Inc.のすべてのカタログと技術パンフレット

-

TC-W100A

2 ページ

-

MEA-100B

2 ページ

-

MIB-300A/600A

2 ページ

-

AMADA WELD TECH

24 ページ

-

HF-2700A / HF-2500A

4 ページ

-

CD-V Series

2 ページ

-

ISQ Series

3 ページ

-

IPB-5000A-MU

2 ページ

-

MFP60 for aws3

2 ページ

-

MFP25 FRO AWS3

2 ページ

-

Series 320

2 ページ

-

newhorizon

3 ページ

-

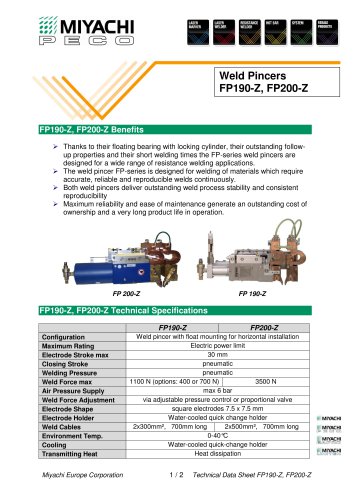

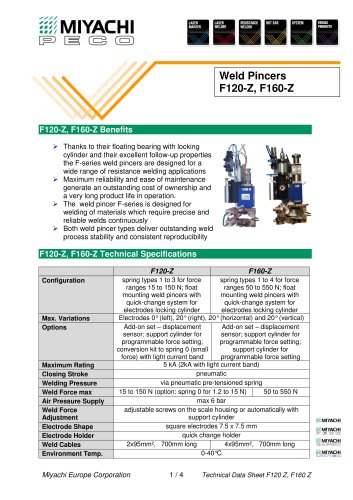

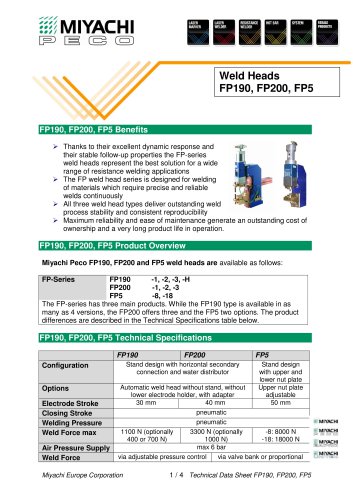

F120, F160, FD120

4 ページ

-

KN-II Series

2 ページ

-

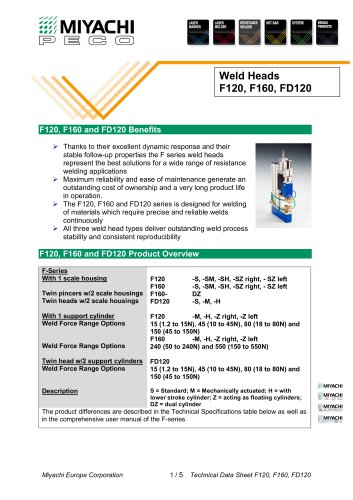

MH Weld Head Range

4 ページ

-

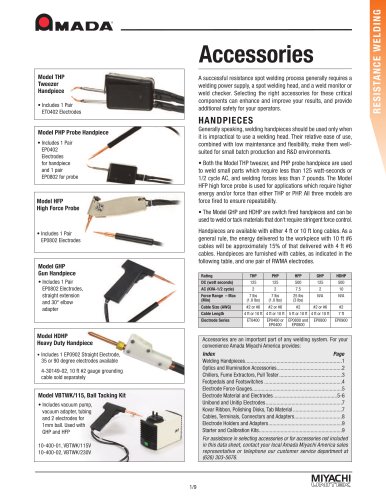

Accessries

9 ページ

-

ML-5120A

2 ページ

-

Systems

16 ページ

-

ML-5120

2 ページ

-

DC29-UB29-UB29A

4 ページ

-

LF Series Lasers

2 ページ

-

SA2200 Dual Oven

2 ページ

-

Heat Staking

2 ページ

-

Systems Datasheet

16 ページ

-

AX5000 Glovebox

2 ページ

-

MX2000 Glovebox

2 ページ

-

Pulsed-Heat Hot-Bar

10 ページ

-

Benchmark SM8500

2 ページ

-

vacuum bakeout oven

2 ページ

-

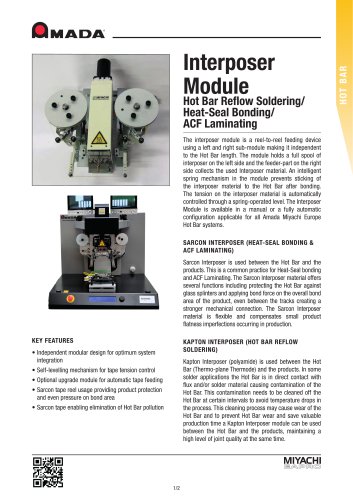

Interposer Module

2 ページ

-

Laser Marker Motion

2 ページ

-

Laser Accessories

7 ページ

-

Alpha Series

2 ページ

-

AX-5000 Glovebox

2 ページ

-

Thin Line Weld Heads

8 ページ

-

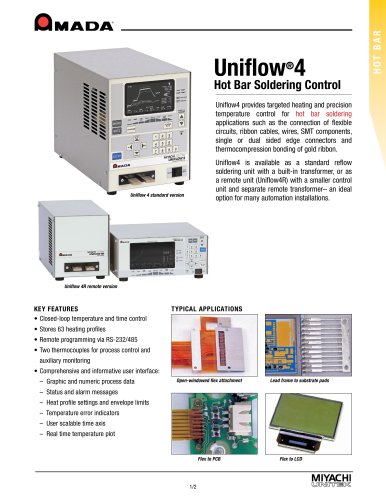

Uniflow 4

2 ページ

-

Pulsar

2 ページ

-

LW300-600A

2 ページ

-

LW50A-70-150A

2 ページ

-

LW5-15-25A

2 ページ

-

LF Series

2 ページ

-

50 Series Weld Heads

4 ページ

-

MH Series Weld Heads

4 ページ

-

MG3

12 ページ

-

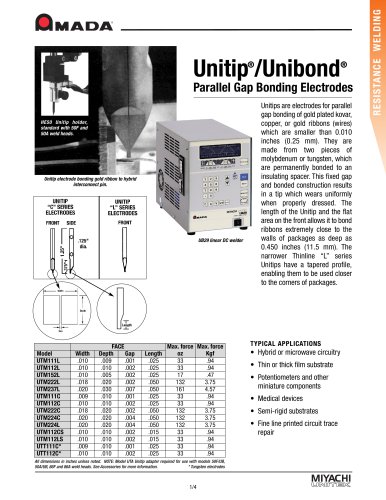

Thin-line

8 ページ

-

IS series

2 ページ

-

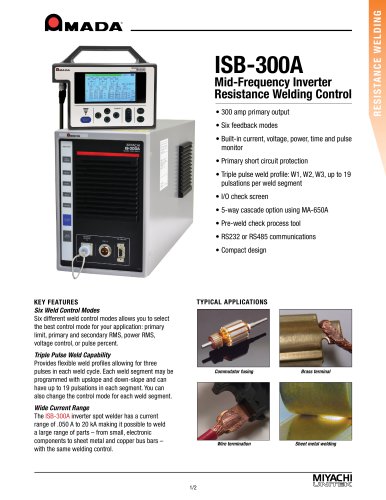

ISB-300 A

2 ページ

-

Accessoires

9 ページ

-

DC25, UB25

4 ページ

-

Bonding Heads

2 ページ