カタログの抜粋

Servo Motor Driven Weld Head • Programmable speed and positions • Controlled servo motor actuation eliminates overforce • Force range 15 lbs to 110 lbs. • Durable and robust head design • Displacement and force options • Remote control I/O and PC communication 73 Opposed Weld Head Designed for use in automation or benchtop welding, Miyachi Unitek’s Model 73 and Model 73-Z weld heads offer fast, repeatable electrode motion control for a wide range of resistance welding applications. The Model 73 weld head is an easyto-program, state-of-the-art servo motor controller that allows precise programming of electrode position and speed for up to 31 different weld schedules. The 73-Z pincer weld head has self centering electrode clamping and floating mechanism to ensure the part is centered between the electrodes every time. 73-Z, Pincer Weld Head TYPICAL APPLICATIONS KEY FEATURES • Individual speed control for “stroke to search” and “search to weld” Good for automation – increases flexibility and throughput • Machine builder module – A module option without a lower electrode or extrusion provides convenient machine mounting • 31 schedules – Write and save up to 31 motion schedules • Fast follow-up – Less weld splash, more consistent welds • Overforce protection – Ensures concise, repeatable force, less weld splash, reduced part deformation • Force independent of part height – Constant applied force ensures weld repeatability • Easy programming – Fast, efficient schedule adjustment • “Soft-touch” part clamping – Minimizes impact force – allows verification of part alignment prior to welding Terminal connections for sensors Magnet wire to tang termination Joining of stamped sub-assemblies

カタログの1ページ目を開く

R E S I S TA N C E W E L D I N G servo motor driven weld head Programmable Electrode Positions – ACCURATE TO .004” • The “Home” position allows for easy access during maintenance. • The electrode is in the “Upstop” position in the “Ready” state. • The first level of the footswitch moves the electrode down to the “Search” position at a programmable “Soft-touch” speed. • The second level of the footswitch applies the pre-set welding force, with no overforce. • The programmable “Downstop” inhibits welding if parts are not present. SPECIFICATIONS Model Number Weld Force Method Spring force...

カタログの2ページ目を開くAMADA WELD TECH Inc.のすべてのカタログと技術パンフレット

-

TC-W100A

2 ページ

-

MEA-100B

2 ページ

-

MIB-300A/600A

2 ページ

-

AMADA WELD TECH

24 ページ

-

HF-2700A / HF-2500A

4 ページ

-

CD-V Series

2 ページ

-

ISQ Series

3 ページ

-

IPB-5000A-MU

2 ページ

-

MFP60 for aws3

2 ページ

-

MFP25 FRO AWS3

2 ページ

-

Series 320

2 ページ

-

newhorizon

3 ページ

-

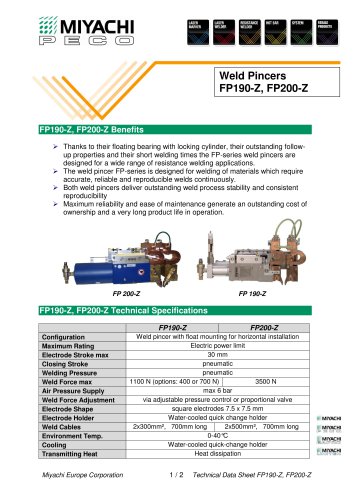

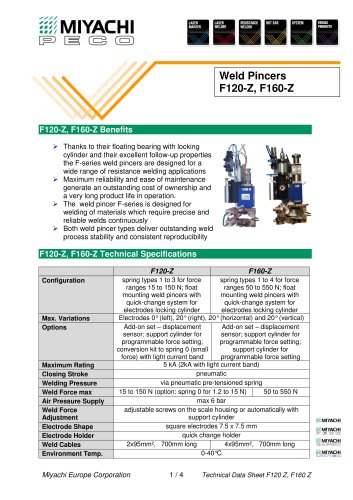

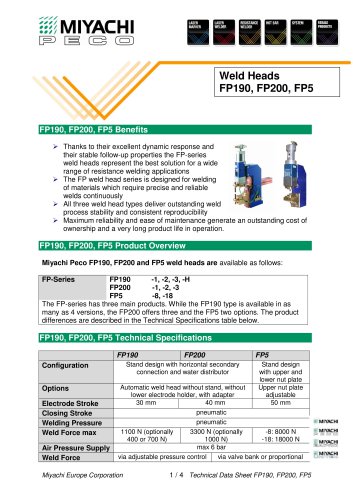

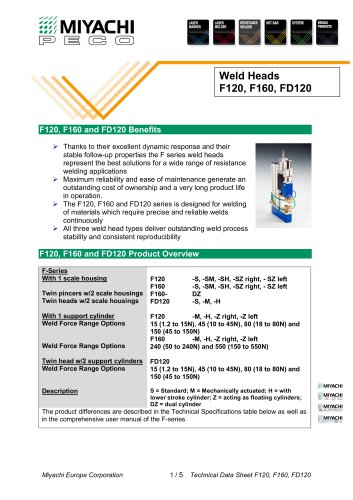

F120, F160, FD120

4 ページ

-

KN-II Series

2 ページ

-

MH Weld Head Range

4 ページ

-

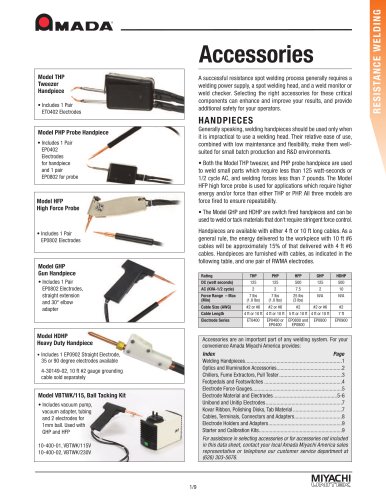

Accessries

9 ページ

-

ML-5120A

2 ページ

-

Systems

16 ページ

-

ML-5120

2 ページ

-

DC29-UB29-UB29A

4 ページ

-

LF Series Lasers

2 ページ

-

SA2200 Dual Oven

2 ページ

-

Heat Staking

2 ページ

-

Systems Datasheet

16 ページ

-

AX5000 Glovebox

2 ページ

-

MX2000 Glovebox

2 ページ

-

Pulsed-Heat Hot-Bar

10 ページ

-

Benchmark SM8500

2 ページ

-

vacuum bakeout oven

2 ページ

-

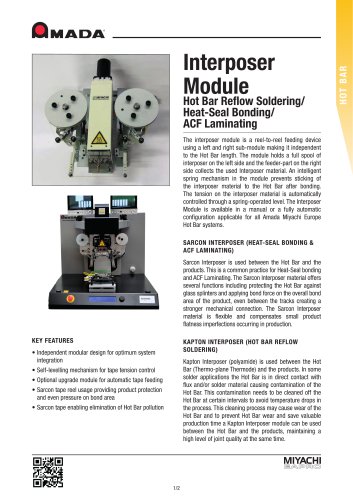

Interposer Module

2 ページ

-

Laser Marker Motion

2 ページ

-

Laser Accessories

7 ページ

-

Alpha Series

2 ページ

-

AX-5000 Glovebox

2 ページ

-

Thin Line Weld Heads

8 ページ

-

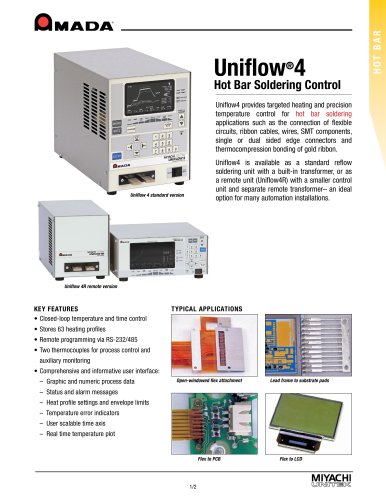

Uniflow 4

2 ページ

-

Pulsar

2 ページ

-

LW300-600A

2 ページ

-

LW50A-70-150A

2 ページ

-

LW5-15-25A

2 ページ

-

LF Series

2 ページ

-

50 Series Weld Heads

4 ページ

-

MH Series Weld Heads

4 ページ

-

MG3

12 ページ

-

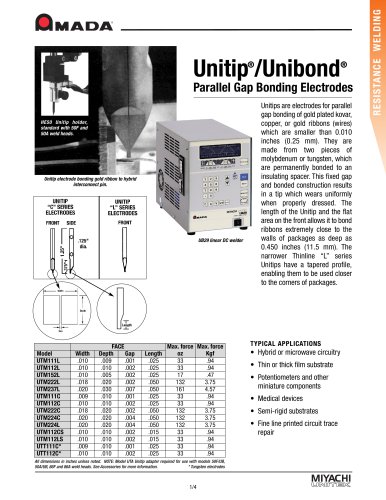

Thin-line

8 ページ

-

IS series

2 ページ

-

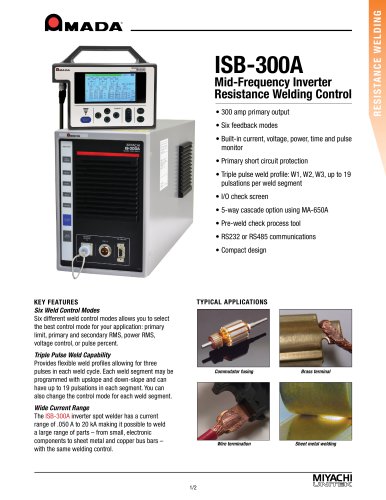

ISB-300 A

2 ページ

-

Accessoires

9 ページ

-

DC25, UB25

4 ページ

-

Bonding Heads

2 ページ