カタログの抜粋

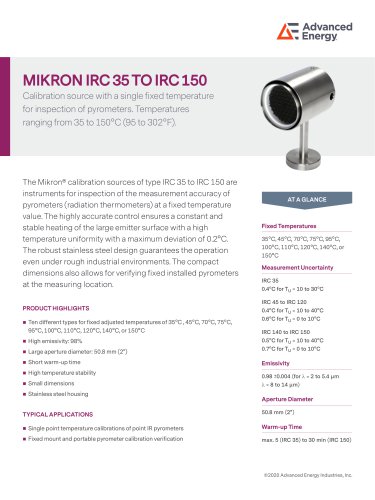

Infrared camera system for continuous temperature measurement and monitoring in boilers and furnaces from 500 to 1600°C (932 to 2912°F). The BoilerSpection™ SD thermal imaging system provides continuous, real-time, through-flame imaging plus is resilient and robust enough to withstand the harshest conditions. Plant operators need a view inside the boiler, furnace or kiln to increase efficiency, improve emissions, and lower operating costs. BoilerSpection includes state-of-the-art optics, infrared cameras, an auto-retraction device, networking components and software to control the entire system remotely. The LumaSpec RT software is a powerful tool for analysis and historical trending, outputs to automation and DCS, along with a real-time web server to broadcast images over the plant’s network. Infrared image from BoilerSpection SD system in grayscale color palette PRODUCT HIGHLIGHTS Capture lost boiler capacity by reducing unnecessary cleanings Infrared image in LumaSpec RT software Increase efficiency by improving heat transfer with precise knowledge of slag and ash buildup Lower maintenance costs by optimizing cleaning and identifying large deposits (clinkers) before they cause damage to boiler tubes Optimize fuel-switching by directly and accurately measuring ash rate and uniformity as fuel changes Manage combustion by tracking uniformity of ash deposits

カタログの1ページ目を開く

Available Options ■ LumaSpec RT web server functionality for remote broadcasting of data over plant network(s) ■ I/O outputs and relay outputs for DCS, PLC, or connection to trigger cleaning equipment ■ Interface for 3rd party plant historical archiving programs ■ OPC and Modbus Support (Serial and IP) ■ RAID memory systems ■ Service offerings: installation, maintenance, and training

カタログの2ページ目を開く

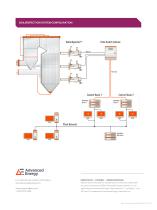

BOILERSPECTION SD DIMENSIONS SYSTEM INSTALLATION The BoilerSpection system can be installed and commissioned either while the boiler is operating or during an outage. The cameras system mounts to the furnace wall via a mounting plate. Advanced Energy offers a choice of weld-on or bolt-on mounting plates. Exact dimensions can be customized by request. The standard BoilerSpection system has the following requirements: ■ Facility connections ■ Ports with a 2” (50 mm) clearance ■ Less than 330’ (100 m) distance between cameras and the field switch cabinet ■ Less than 820’ (250 m) distance from...

カタログの3ページ目を開く

BOILERSPECTION SYSTEM CONFIGURATION Field Switch Cabinet Ethernet Fiber Optic Control Room 2 BoilerSpec Advanced Energy For international contact information visit advancedenergy.com. sales.support@aei.com +1 970 221 0108 PRECISION | POWER | PERFORMANCE Specifications are subject to change without notice. Not responsible for errors or omissions. ©2019 Advanced Energy Industries, Inc. All rights reserved. Advanced Energy®, BoilerSpection™, LumaSpec™, and AE® are U.S. trademarks of Advanced Energy Industries, Inc.

カタログの4ページ目を開くADVANCED ENERGYのすべてのカタログと技術パンフレット

-

LCM brochure

4 ページ

-

eVos me Datasheet

2 ページ

-

eVos datasheet

2 ページ

-

eVerest datasheet

12 ページ

-

Ascent AMS datasheet

6 ページ

-

Ascent AP datasheet

8 ページ

-

Ascent DMS datasheet

8 ページ

-

Impac Pyrometer Overview

28 ページ

-

Basic Bus Module

2 ページ

-

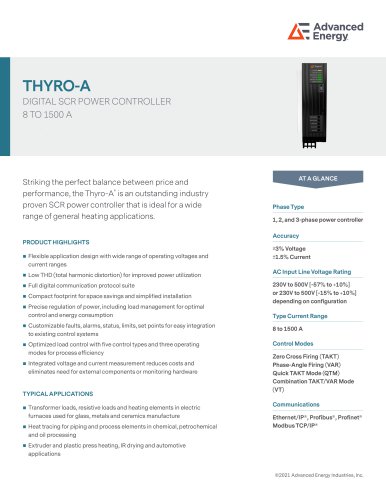

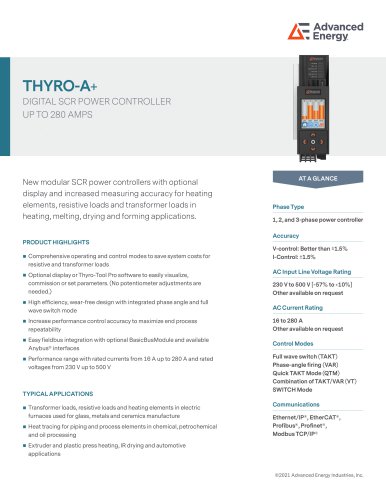

Thyro S Series Datasheet

10 ページ

-

Thyro A Series Datasheet

10 ページ

-

FBG Analyzer Series

4 ページ

-

xgen series

56 ページ

-

THYRO-FAMILY ACCESSORIES

12 ページ

-

Luxtron FOT probes

2 ページ

-

Gas Sensing Overview

16 ページ

-

XSOLO

8 ページ

-

XF

8 ページ

-

COOLX®600

8 ページ

-

COOLX®1800

12 ページ

-

COOLX®1000

11 ページ

-

IMPAC IS 50-LO/GL

4 ページ

-

IMPAC IPE 140

8 ページ

-

IMPAC IPE 140/39

2 ページ

-

IMPAC SERIES 8 PRO

8 ページ