Website:

WIWA

Website:

WIWA

Group: pfp

Catalog excerpts

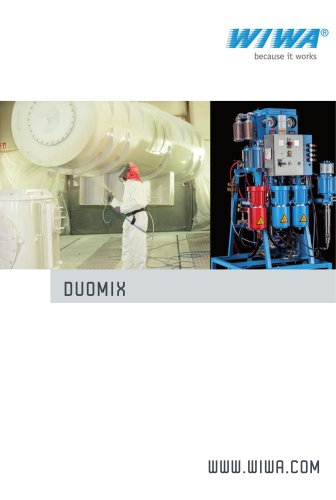

PERFECT SOLUTIONS FOR EVERY APPLICATION AREA... ...THROUGH A MODULAR SYSTEM CONCEPT The globally proven WIWA 2K range for large-surface coatings The DUOMIX demonstrates its particular strengths when used for the processing of highly viscous, solvent-free 2K or 3K materials with extremely short pot lives (under 30 seconds). Huge advantages in all application areas • Rapidly interchangeable mixing ratio (process assurance) • Mixing ratios of 1:1 to 10:1 • Feed volumes per double stroke of up to 700 cc • Pressure ratios of up to 85:1 • High efficiency • Large performance rang • Individual...

Open the catalog to page 2

Application areas Waste water treatment Marine and offshore industry Rail Container construction Pipe and pipeline coating Pipeline refurbishment Steel and hall construction Wagon factories Container construction Building and corrosion protection Wind power industry Tank construction Secondary overflow protection Paint supply systems Materials Low and high-viscose materials 2-component materials 3-component materials Solvent-based materials High-solid materials Solvent-free materials

Open the catalog to page 3

EFFICIENT AND ENVIRONMENTALLY FRIENDLY... ...WIWA DUOMIX RANGE Advantages that add up • Modular system concept • Powerful performance with high proportioning accuracy • Low maintenance due to consistently high WIWA quality standard • No faulty coatings due to automatic shut-off upon exceeding pressure limits • Long service life due to non-tipping direct drive of the material pumps • Simple documentation of the work through optional data logging • Simple and safe operation Environmentally friendly This is how WIWA protects the environment • Reduced material and flushing media consumption due...

Open the catalog to page 4

Efficient Reduced drying, storage and downtime costs • Due to its mixing ratio, the DUOMIX can process materials with the shortest pot lives and curing times in almost all application areas. This reduces throughput, drying and downtime costs • Only the required material quantity is mixed meaning no material loss Working time savings • Rapid start-up • Rapid shut-down of the system after work, because it is only necessary to flush the spray hose between the mixing block and gun • Application of high layer thicknesses in a single working process • Interruption-free work through the use of the...

Open the catalog to page 5

MIXING RATIO 1:1 TO 10:1... ...SIMPLE - FLEXIBLE - ASSURED The guarantee for precise proportioning and variable mixing • Flexible: WIWA DUOMIX – the world‘s only 2K system that offers you the flexibility of a variably adjustable 2K system and the assurance of a fixed mixing ratio, and which can be used as a 3K system. • Simple: With just a few actions, you set the DUOMIX to the desired mixing ratio. Time-consuming ratio checking and adjustment are superfluous, and accidental adjustment is impossible. • Assured: The fixed mixing ratio provides you with process assurance. Accidental...

Open the catalog to page 6

The basic modules 1 Air motor The air motor with de-icing system and maintenance unit in robust metal design. It is equipped with a piston rod and two guide axes, which are guided in the upper and lower section. This guarantees the non-tipping direct drive of all material pumps, whilst the wear of packing and piston rods is also minimised. 1 2 Material pump combination If new requirements need alternative mixing ratios the material pumps can be manually exchanged within minutes. A closed ushing media chamber separates the air motor and material pumps. The ushing media prevents paint...

Open the catalog to page 7

MODULES OF PERFECTION FOR YOUR... ...INDIVIDUAL SYSTEM Heating systems Feed pumps and feed systems Flushing pumps A range of different heating options are available for low outside temperatures, highly viscose materials and coatings with high temperature processing: When processing highly viscose materials you obtain DUOMIX parts, which ensure an optimally tailored supply: Flushing pumps for cleaning all system parts that come into contact with the mixed material. • EX-protected material heaters (3.5 kW) approved up to 450 bar • Piston pump • Hose heating (electrically / hot-water heated) •...

Open the catalog to page 8

Material pumps Mixing block High pressure filter Pressure and proportioning monitoring The fixed mixing ratio is determined based on the sizes of the material pumps and hardener pump. The pneumatic mixing block with flushing device and static mixer is available with manually actuated valves or remote control. A rupture disc device, integrated as standard, protects the system against exceeding the maximum permissible working pressure and any damage. Using this equipment it is possible to monitor the mixing ratio. In order to avoid defective mixing, the pressures of both components are...

Open the catalog to page 9

THE APPLICATION AREA DETERMINES THE DESIGN ...DUE TO THE MODULAR SYSTEM CONCEPT The optimum design and equipment From delivery container to airless spray gun - the diversity of the modules, in combination with the range of performance variants, is almost limitless. Modular construction The design of the DUOMIX system is tailored to the application area and the spray material. Depending on the application area, the WIWA DUOMIX system can be designed as a fixed, complete system, or as spatially separated modules. The DUOMIX principle: Individually modular Complete system Air motor Material...

Open the catalog to page 10

WIWA DUOMIX... ...suitable for short pot lives In use globally for the processing of highly viscous, solvent-free 2K or 3K materials with particular strengths with extremely short pot lives (under 30 seconds). ...for high to low viscose materials Large performance range for almost all low to high viscose 2K coatings. ...with interchangeable mixing ratio With just a few actions it is possible to change the material pumps and therefore also the material ratio. ...with higher wear resistance Non-tipping direct drive of all material pumps. ...reliable in all temperature ranges Decentralised use...

Open the catalog to page 11All WIWA catalogs and technical brochures

-

WIWA DUOMIX PU 540

2 Pages

-

PHOENIX GX

16 Pages

-

WIWA PROFESSIONAL GX

2 Pages

-

WIWA accessories-catalogue

61 Pages

-

WIWA PHOENIX GX Series

2 Pages

-

WIWA ND-Pumps

2 Pages

-

Injection: WIWA INJECT HD 1

8 Pages

-

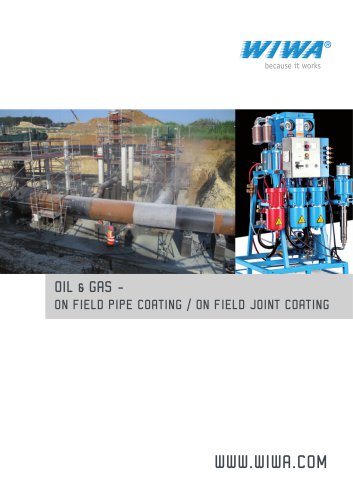

Pipeline-Field Coating

2 Pages

-

Pipeline oil & gas

4 Pages

-

WIWA AGITATING STATIONS

2 Pages

-

High Pressure Cleaner

2 Pages

-

WIWA DUOMIX PU Gesamtkatalog

8 Pages

-

WIWA FLEXIMIX 1 ND

2 Pages

-

Delivery Program

28 Pages

-

WIWA Datalogger

2 Pages

-

WIWA Fluid Heater

2 Pages

-

WIWA DUOMIX 270

2 Pages

-

WIWA HERKULES GX

2 Pages

-

WIWA RS 1

2 Pages

-

WIWA Motar pump

2 Pages

-

WIWA POWERPACK XL

2 Pages

-

WIWA Schlichte

2 Pages

-

WIWA DUOMIX PFP

8 Pages

-

WIWA PROFIT/PHOENIX

16 Pages

-

WIWA PROFESSIONAL/HERKULES

16 Pages

-

WIWA Effektiv

2 Pages

-

WIWA VULKAN

8 Pages

-

WIWA Low Pressure Pumps

2 Pages

-

WIWA FLEXIMIX 2

2 Pages

-

OPTIMA 2100 AIR COMBI

2 Pages