Website:

WIWA

Website:

WIWA

Group: pfp

Catalog excerpts

CRAFT TRADES, WINDOW & FURNITURE MANUFACTURING INDUSTRY MARINE AND OFFSHORE INDUSTRY PIPES AND PIPELINES FIRE PROTECTION

Open the catalog to page 1

It all started with spray nozzles, which precision mechanic Wilhelm Wagner manufactured in the 1940s. Today - 65 years after it was established - WIWA Wilhelm Wagner GmbH & Co. KG supplies first class coating systems, spray painting equipment, injection and fluid handling systems to every country around the world. 1950 Company founded in Lahnau, WIWA develops and makes oil pumps and lubrication guns 1967 The first Airless spray painting units are sold 1968 New Airless spray painting units and underbody coating pumps are added to the product range 1970 New products -AIRLESS 10.000, AirCombi...

Open the catalog to page 2

A tradition of reliability and precision dating back more than 65 years: WIWA Wilhelm Wagner GmbH & Co. KG, established in 1950, is one of the world’s leading designers and manufacturers of 1C (single-component) and 2C (plural-component) airless spray-painting units, fluid-handling and material-extrusion pumps and injection systems. The range of applications of WIWA equipment and systems extends from painting, coating and bonding in the mechanical engineering and vehicle manufacturing industries through large-surface and thick-layer coatings in the marine and offshore industries, masonry...

Open the catalog to page 3

PRODUCT RANGE EXAMPLESOur 1K Product Offering Hydraulic power pack

Open the catalog to page 4

OVERVIEW OF SPRAYING METHODS WIWA PROFESSIONAL and HERKULES, available as Airless spraying units WIWA PROFESSIONAL, available as Air Combi finishing systems for painting lines and paint circulation systems WIWA PROFESSIONAL and HERKULES, also available as Hot Job units with integrated fluid heater High pressure Air-assisted painting Economical, environmentally friendly spraying method with excellent surface area coverage at high pressures. The Air Combi combines the advan ages t of Airless and conventional spraying techniques. The high pressure pump draws the spraying agent from any...

Open the catalog to page 5

COATINGS IN CRAFT TRADES, FURNITURE & WINDOW MANUFACTURING WIWA paint spraying equipment is used daily in a wide range of different craft businesses, be it joineries, window manufacturers or piano makers. Given their performance spectrum and numerous spec options, they are suited to use in conjunction with nearly all application methods and materials. PHOENIX – the new powerful multi-purpose equipment for wood varnishing and metal painting as well as other types of coating in industry and craft trade. Most suitable for the timber and metal processing industry as well as painters, spray...

Open the catalog to page 7

CORROSION PROOFING IN STEEL, TANK AND CONTAINER CONSTRUCTION Steel: stress and strain caused by environmental influences, weather conditions and mechanical impact are as varied as its different uses. That’s why corrosion proofing plays such a key role at metal processing companies. The use of corrosion proofing materials is substantial – correspondingly high standards are placed on the effectiveness of the coating-application technology. WIWA provides an extensive range of equipment to handle single- and two-component materials in different mix ratios MATERIALS: Polyurea, epoxy resin,...

Open the catalog to page 9

INDUSTRIAL PAINTWORK Frequent color and material changes with a wide range of different pressure settings and viscosities are standard industrial paintwork requirements. Decorative or protective surface coating systems have to operate at maximum reliability in industrial environments – and deliver absolute flexibility. The WIWA FLEXIMIX’s name says it all. It is ideal for use as a multi-paint system with variable-setting mix ratios for solvent- and water-based paints. The FLEXIMIX 1 facilitates fast color changes between up to ten different paints and lacquers. Its precision delivers...

Open the catalog to page 11

CORROSION PROOFING FOR MARINE AND OFFSHORE STRUCTURES For more than 60 years now WIWA has been supplying domestic and international shipyards with robust and effective coating systems, specially designed for use in the most extreme weather conditions. Irrespective of whether ships, oil and gas platforms or port facilities are involved, maritime designs and structures are particularly exposed to aggressive environmental influences. They have to withstand the permanent impact of wind and salt water for many years. Cracks and leaks in offshore structures not only threaten the safety of the...

Open the catalog to page 13

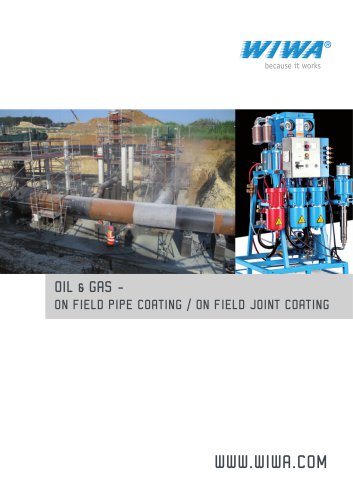

PIPELINE COATINGS AND LINING A key factor in the cost effectiveness of any pipeline coating and lining is both the longevity of such a measure as well as the cost effectiveness of the application method. WIWA DUOMIX systems are ideally suited to use in coating systems which facilitate fully automatic and simultaneous application of coating materials to the inner and outer surfaces of pipes and pipelines. Many large scale projects that WIWA has been involved with impressively demonstrate that WIWA is one of the leading manufacturers of equipment for first-coating and refurbishing pipes and...

Open the catalog to page 15

PRODUCTION AND PROTECTION OF WIND TURBINES As with other steel structures, corrosion proofing is very high on the list of priorities in the wind turbine construction industry. As a place partner to a large number of system suppliers and plant engineering companies from this industry, WIWA attaches major importance on continuous product innovation and enhancement. Besides coating equipment for corrosion proofing materials, WIWA also supplies state of the art pump technology for pumping epoxy resins and adhesives which are used, for example, in the manufacture of sandwich design rotor blades...

Open the catalog to page 17

PASSIVE FIRE PROTECTION When buildings catch fire, every minute counts. As soon as the structural steel in any building has reached the critical core temperature of around 550° degrees Celsius, it is in danger of collapsing. Passive fire protection has therefore become an absolute must. We have enhanced our application equipment for fire-protection materials accordingly in close collaboration with leading materials manufacturers. Our proven systems can be used in the most extreme of conditions – and the WIWA DUOMIX PFP 333 -Zone 1 version has also been certified for use on offshore...

Open the catalog to page 19All WIWA catalogs and technical brochures

-

WIWA DUOMIX PU 540

2 Pages

-

PHOENIX GX

16 Pages

-

WIWA PROFESSIONAL GX

2 Pages

-

WIWA accessories-catalogue

61 Pages

-

WIWA PHOENIX GX Series

2 Pages

-

WIWA ND-Pumps

2 Pages

-

Injection: WIWA INJECT HD 1

8 Pages

-

Pipeline-Field Coating

2 Pages

-

Pipeline oil & gas

4 Pages

-

WIWA AGITATING STATIONS

2 Pages

-

High Pressure Cleaner

2 Pages

-

WIWA DUOMIX PU Gesamtkatalog

8 Pages

-

WIWA FLEXIMIX 1 ND

2 Pages

-

WIWA Datalogger

2 Pages

-

WIWA Fluid Heater

2 Pages

-

WIWA DUOMIX 270

2 Pages

-

WIWA HERKULES GX

2 Pages

-

WIWA RS 1

2 Pages

-

WIWA Motar pump

2 Pages

-

WIWA POWERPACK XL

2 Pages

-

WIWA Schlichte

2 Pages

-

WIWA DUOMIX PFP

8 Pages

-

WIWA PROFIT/PHOENIX

16 Pages

-

WIWA PROFESSIONAL/HERKULES

16 Pages

-

WIWA Effektiv

2 Pages

-

WIWA VULKAN

8 Pages

-

WIWA Low Pressure Pumps

2 Pages

-

WIWA FLEXIMIX 2

2 Pages

-

WIWA DUOMIX

16 Pages

-

OPTIMA 2100 AIR COMBI

2 Pages