Website:

Whizcut of Sweden AB

Website:

Whizcut of Sweden AB

Catalog excerpts

The World of WhizCut Smart Solutions on the Cutting Edge Demand on production for small parts around the world is continuously increasing and higher expectations are put on the producers of these parts. This is where WhizCut comes in. At WhizCut we understand the day to day challenges the users of automatic lathes are up against. To assist these users WhizCut has developed a wide range of useful products for all automatic lathes around the globe. We try, to put it simple, to find new solutions for existing problems within the world of small part machining. Our company is based on these new...

Open the catalog to page 2

We have extended our WhizHip line with new toolholders. WhizHip is now available in left hand and also a new version, CA, specially developed for Parting off small parts. The CA model Toolholder has a narrow front head so the part becomes easy accessible for the Sub Due to very high popularity of our inserts with extra high cutting rake angle we have extended this line with new versions. • Turning inserts with smaller or no corner radius, J15ER HP16-0, K15ER VLR12-12 is developed for where there is a need to profile or backturn with a small radius. This tool makes a 0,1mm radius in the...

Open the catalog to page 3

WhizCut of Sweden AB Company Information Introducing WhizCut Committed to Quality in Every Way WhizCut has always taken pride in delivering top quality tooling. All inserts and toolholders are thoroughly examined in top of the range measuring microscopes. Every single cutting edge is also checked at over 60 times enlargement before being packed in transport safe packaging. We at WhizCut therefore guarantee that there is no chipping or other faults in our products. Fast shipment and reliable deliveries are also a major factor in the quality of our products. For this reason we always make...

Open the catalog to page 4

External Toolholders and Inserts In the past 15 years there has been a very big change in production of small parts. Many parts that previously were made in cam type machines and traditional CNC machines are now produced in Swiss Type Automatic Lathes. Machining in these machines is different from machining in traditional machines and the great advantages of using swiss turning can only be obtained with the right tooling. All WhizCut inserts are specially developed for these machines and today WhizCut has the widest range of inserts specially developed for Swiss type automatic lathes. Only...

Open the catalog to page 5

EXTERNAL TOOLING EXTERNAL TOOLING Technical Information Technical Information Only Two Toolholders for All Applications WhizFix Clamping WhizCut offers the widest range of external carbide inserts for Swiss type automatics on the market. Our goal is to offer great performing WhizCut tooling for all applications our customers need in their lathes. WhizCut inserts are divided into 2 different application styles; radial turning and front turning. The toolholders for radial turning and front turning have been optimized for their targeted application. As a result the user of WhizCut inserts only...

Open the catalog to page 6

Front Turning: J-type Inserts & Toolholders (straight turning, copy turning, groove turning, profile turning) Turning direction Resulting cutting force The J-type inserts are available in many variations to enable the most suitable combination of cutting rakes, shapes, corner executions, chip control and grades of The J-type insert is tilted in the toolholder to give the best clearance and maximum stability in the tooling. The resulting cutting force is illustrated beside. Recommended Cutting Data J-type Inserts Carbon steel Feed rate Material Hardness Feed rate Alloy steel Stainless steel...

Open the catalog to page 7

J-TYPE INSERTS J-TYPE INSERTS Groove, Finish turning | Use with J-type Toolholders Turning - Selecting the Best Insert • • • • 3° Gives the strongest tool and smoother finish 12° Gives a strong tool and good finish 33° Medium strong tool, wiper good for smooth finish 48-53°: Less strong tool, wiper needed for smooth finish 0-2° for short-chipping materials 3-8° for harder long-chipping materials 8-16° for long-chipping materials 16-20° for sticky long-chipping materials P - Line style inserts for sticky and exotic materials Large axial relief Weaker tool • Style H = Long chips and/or high...

Open the catalog to page 8

Radial Turning: K-type Inserts & Toolholders (back turning, grooving, threading and parting off) Turning direction Resulting cutting force The K-type inserts are used for back turning, thread- ing, grooving and parting off. WhizCut has a wide range of inserts for these applications making it possible to always get the correct insert for the application. The K-type insert is only slightly tilted in the toolholder to give enough clearance while maintaining maximum stability. The resulting cutting force is illustrated beside. WhizCut has several different types of toolholders for parting off,...

Open the catalog to page 9

K-TYPE WHIZHIP TOOLHOLDERS K-TYPE INSERTS Backturning, Grooving, Threading and Parting off Grooving and Threading Style G | Inserts for Grooving T For more info on WhizHip See page 11 B WSK | WhizHip Toolholders for High Pressure Coolant Extended Range Price Plug Screw Key Stock Group WPK | WhizHip Pin type Toolholders for High Pressure Coolant Pin + Price WhizFix Clamping Price group Price group Style GR | Inserts for Radius Grooving Inserts B Price f Insert Plug Screw Key Stock Group Stock status: WSK | WhizHip Toolholders for Parting off Small Parts All angles are shown when mounted in...

Open the catalog to page 10

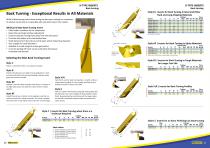

K-TYPE INSERTS K-TYPE INSERTS Back turning Back turning Back Turning - Exceptional Results in All Materials Style B | Inserts for Back Turning in Steel and Other Hard and Long-Chipping Materials WhizCut Backturning inserts have during the past years helped our customers to achieve results that is not possible with any other tools in the market. WhizCut B Style Back Turning Insert Gives better roundness on the component Keeps the size longer without adjustment Controls chips by moving them away from the work piece Curls the chip before it hits the finished face Small distance from the side...

Open the catalog to page 11All Whizcut of Sweden AB catalogs and technical brochures

-

Whizcut 2019

37 Pages

-

Kemmer

244 Pages

-

WhizHold

104 Pages

-

Kemmer GripLock 2016

244 Pages

-

WhizCut 2013

56 Pages

Archived catalogs

-

WhizHip Connect 2017-03

8 Pages

-

Catalogue whizcut 2016

56 Pages

-

Catalogue of Kemmer GripLock

226 Pages

-

WhizHip by HEB

8 Pages

-

WhizCut Catalogue on Threading Tools

24 Pages

-

Catalogue 835

36 Pages