Website:

Weller

Website:

Weller

Group: Apex Tool Group

Catalog excerpts

WR 3M - Innovation newly designed Technical data Weller Flexibility. Refer to the matrix to make your choice of connecting tools for the WR 3M. Soldering Tips Plug-in adjusted soldering tip set for WMRT Soldering tips forWMRP SMT soldering tip for reworks on SMT components Soldering tips for micro soldering pencil WMP Soldering tips for soldering iron WSP 150 Additional Safety Rests Make your choice of connecting tools.

Open the catalog to page 3

Weller has developed a new design of repair station to the highest level: the WR 3M. The versatile repair station is specifically tailored to the needs and requirements of pro- fessional repairs to latest-technology electronic sub-assemblies in industrial production engi- neering and in the repair and laboratory fields. 3 independent tool channels with automatic tool detection guarantee the simultaneous operation of 3 soldering tools. Precise temperature control performance at the soldering tip is guaranteed by the digital control electrotechnology together with su- perior-quality sensor...

Open the catalog to page 5

High-Speed Micro Tools All Weller High-Speed Micro Tools such as the WMRP micro soldering bit and the WMRT micro desoldering tweezers can be connected. But also extremely powerful bits, such as the new HAP 200 hot-air pencil, can be easily flow that is adjustable. Electronic temperature control from 50°C to 550°C. Different nozzles available as accessory. Finger switch controls adjustable pump. (For use with WR 3M only.)

Open the catalog to page 6

The WR 3M is equipped with a mini USB port. The extensive PC software supplied can be used to update the software on the control unit. Monitor software for monitoring, para- meterising and data logging is included in Operation simplicity The big LCD display allows clear information Innovative special functions such as automatic channel changing, temperature preselection buttons for each channel, Factory Calibration The newly developed, innovative desoldering system facilitates soldering and desoldering The desoldering system can be connected to the additional vacuum channel (pick up) of...

Open the catalog to page 7

Technical data Mains supply voltage: Power consumption: Safety class: Temperature control Temperature accuracy: Temperature stability: Additional Pump: Equipotential bonding: Soldering and Desoldering iron stepless Controllable temperature range is Max. delivery rate 18 l/min Max. delivery rate 1.7 l/min I HAP 200 Hot-air pencil with WDH 30 Safety rest ■ DSX 80 Desoldering iron with WDH 30 Safety rest ■ WP 80 Soldering iron with WDH 10T Stop + go Safety rest Version with Inline Desoldering iron I HAP 200 hot-air pencil and WDH 30 Safety rest I DXV 80 desoldering iron with WDH 40 Safety rest...

Open the catalog to page 8

WR 3M – Innovation newly designed 3 tool channels with automatic tool detection Large LCD display Own vacuum channel for pick-up USB port Innovative special functions Comprehensive PC software All High-Speed Micro-Tools can be connected New powerful hot-air pencil

Open the catalog to page 9

Weller Flexibility Refer to the matrix to make your choice of connecting tools for the WR 3M. (See Matrix page 27) HAP 200 Hot air pencil set DSX 80 Desoldering iron set and service kit HAP 200 005 27 117 99 DSX 80 005 13 183 99 The HAP 200, 200 W/24 V, provides a directional hot airflow that is adjustable and static-free. Electronically temperature controlled from 50°C to 550°C. Different nozzles available as accessories. Finger switch controls speed adjustable pump. Hot air pencil set, consisting of HAP 200 with finger switch, WDH 30 Safety rest for pencil, nozzle 1,2 mm and 3,0 mm, key...

Open the catalog to page 10

WMRP Soldering pencil set for RT soldering tips WP 80 Micro Soldering pencil set WMRP 005 29 190 99 WP 80 005 29 181 99 The RT soldering tips have an extremely short heat-up time. All component parts of the system, such as the sensor and heating element, are designed for optimum heat transfer. This ensures absolute efficiency in the utilization of the power provided by the supply unit. The recovery time is minimized. Changing soldering tips is quick, easy, and, most importantly, requires no tools. WMRP set, consisting of WMRP soldering pencil, RT 3 soldering tip and WDH 50 Safety rest. The...

Open the catalog to page 11

Weller Flexibility Refer to the matrix to make your choice of connecting tools for the WR 3M. (See Matrix page 27) WMP Micro soldering pencil set WSP 150 Soldering iron set WMP 005 33 153 99 WSP 150 005 29 189 99 The 65 W micro pencil is up to the task with superior performance for both heat-up and thermal efficiency. Suitable to handle all micro components and fine pitch tasks. The WMP provides an extremely short tip-to-grip distance. The heater is integrated into the handle. When the tip wear out the heating element goes on. WMP set consisting of WMP micro soldering pencil and WDH 20...

Open the catalog to page 12

WMRT Tweezers set WTA 50 Tweezers set WMRT 005 13 173 99 WTA 50 005 33 133 99 The new WMRT desoldering tweezers 80 W/24 V enable with their twin parallel adjusted tiplets a significant precise and desoldering of very small SMD components. Placed in the Safety rest WMRTH the tips are automatically switched off for increasing endurance. The tweezers are used to desolder SMD components. The tweezers have two moveable heating elements. WTA 50 set, consisting of WTA 50 Tweezers, AK 51 Safety rest for Tweezers. WST 20 Thermal wire stripper with Safety rest WST 82 Thermal wire stripper with Safety...

Open the catalog to page 13

Weller Flexibility Refer to the matrix to make your choice of connecting tools for the WR 3M. (See Matrix page 27) WSB 80 Solder bath WSB 150 Solder bath WSB 80 005 27 040 99 WSB 150 005 27 042 99 The WSB 80 is a very useful rework preparation tool. The solder bath is temperature controlled continuously from 50˚C to 450˚C via an existing 80 W power source. The solder bath can be used to tin wire ends and clean leads of all extraneous solder particles in preparation for reworking. (Usable for lead free solder.) The WSB 150 solder bath is optimally suited to tin coating and preparation of...

Open the catalog to page 14

four sides heated four sides heated four sides heated four sides heated four sides heated Measuring nozzle

Open the catalog to page 15All Weller catalogs and technical brochures

-

RTU

2 Pages

-

Weller FT Cataloge

52 Pages

-

WellerFT Laserline

4 Pages

-

Weller Catalog - The Original.

356 Pages

-

FlowinSmart Brochure

2 Pages

-

Erem Image Brochure

8 Pages

-

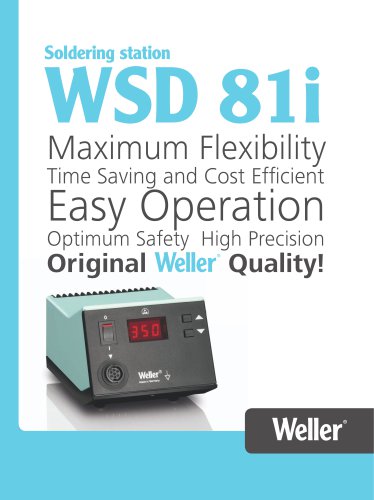

WSD 81i Brochure

12 Pages

-

Generation WT Brochure

13 Pages

-

WTQB 1000 Rework System

5 Pages

-

KDS834A

1 Pages

-

KDS141P

1 Pages

-

KDS14TNP

1 Pages

-

Fume Extraction Solutions

28 Pages

-

wide band gas filter

2 Pages

-

WX2

2 Pages

-

WXD2

8 Pages

-

WAH35

1 Pages

-

Barrel for WSP 80

1 Pages

-

LT1

1 Pages

-

KDS824A

1 Pages

-

KDS301

1 Pages

-

KDS806V

1 Pages