Website:

Webtec

Website:

Webtec

Catalog excerpts

Turbine flow meters with conditioned output and built-in loading valve Milwaukee, WI 53235, USA Tel: +1 (414) 769-6400 sales-us@webtec.com St. Ives, Cambs. PE27 3LZ, UK Tel: +44 (0) 1480 397 400 sales-uk@webtec.com The CTR series of turbine flow meters with built-in loading valve, provide a complete solution to the flow measurement of hydraulic systems on test stands, machine tools and other fixed or mobile applications. The flow meter can be installed anywhere in the hydraulic circuit for production testing, commissioning, development testing and control systems. The compact design allows the CTR series flow meters to be installed where space is limited. The integral loading valve provides smooth progressive pressure control in both flow directions allowing components such as cylinders or motors to be tested without re-plumbing the test connections. The CTR turbine flowmeter has a built-in micro-processor that conditions the signal from the flowmeter to provide an accurate analogue output. This enables you to connect the flowmeter directly into your digital display, PLC or custom DAQ system. Two versions are available offering 4 - 20 mA current loop or 0 - 5 V. * Greater flow accuracy is obtained in the forward direction. l LOADING VALVE: with bi-directional flow and pressure loading capability * disc system, bypasses oil internally in the event of the valve being over pressurised l FLUIDS: Wide range of hydraulic oil, lubrication oils, and fuels standard. Special calibration possible of accessories available including pressure transducers, temperature sensors panel meters and cables. See bulletinss MPT, TP125 and DP130 for details or consult sales office CTR mA model shown Certificate No.8242 Hydraulic measurement and control

Open the catalog to page 1

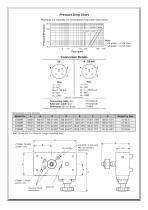

Main ports Flow range CT600R, 800R has limited pressure control below 86 lpm (23 US gpm). The maximum controllable pressure in this region is calculated by: max pressure (in bar) = 5 x flow (lpm) +30 Functional specification Ambient temperature: Fluid type: Fluid temperature: Accuracy: Repeatability: Response Time: Degree of protection*: 5 to 40 °C (41 - 104 °F) Oils, fuels, water glycol, water oil emulsions 5 to 90 °C (41 - 194 °F) continuous use. 15 to 100% of range - 1% of indicated reading Below 15% fixed accuracy of 1% of 15% of full scale Better than ± 0.2% 50 m/s + 1 period CTR-mA,...

Open the catalog to page 2

Pressure Drop Chart Pressure Drop (bar) Hydraulic Oil Viscosity 21 Centistokes (fully open load valve) 10.0 CT600R/CT800R Note 1 UK gallon = 4.546 litres 1 US gallon = 3.785 litres Connection Details Connecting cable (5m) Extension cable (5m) Connector (M12x1 5 pin) Dimensions in mm (inches) Model No A B CT300R CT400R CT600R CT800R Add 20mm (3/4”) to G for full height including feet. D CT300R, CT400R position only One M16 x 2 test point fitted as standard (Not shown) CT600R, CT800R position only Pressure/Temp connections

Open the catalog to page 3

Turbine Flow Meters Accuracy All our flow meters are calibrated at 10 points over the flow range and its performance measured against a flow reference that is traceable to International standards. Accuracy is typically quoted in one of two ways: as a percentage of full scale (the maximum calibrated flow) or as a percentage of the indicated reading (the actual flow). Flow range (Turndown ratio) The accuracy is better described as the uncertainty of the flow reading compared to a known reference. Every flow measurement has an error associated with it, caused by the combination of a large...

Open the catalog to page 4All Webtec catalogs and technical brochures

-

HPM110Digital pressure gauge

3 Pages

-

HPM7000Hydraulic Data Logger

3 Pages

-

FDC140

3 Pages

-

GF series

3 Pages

-

280 series

5 Pages