Website:

Watson-Marlow Fluid Technology Group

Website:

Watson-Marlow Fluid Technology Group

Group: Watson

Catalog excerpts

Watson-Marlow Pumps Group has six world-class factories supported by direct sales operations in 24 countries and distributors in more than 50 countries. For contact details visit our website: SPX Hose Pumps Watson-Marlow Watson-Marlow online Our engineers around the world can help you choose the perfect pump and tubing for your needs. More information? Our brochures are on our website - www.wmpg.com Tel: +44 (0)1326 370370 www.wmpg.co.uk Watson-Marlow Pumps Group Falmouth, Cornwall TR11 4RU, UK

Open the catalog to page 1

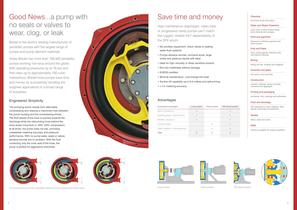

Good News...a pump with no seals or valves to wear, clog, or leak Bredel is the world’s leading manufacturer of peristaltic pumps with the largest range of pumps and pump element materials. Today Bredel has more than 100,000 peristaltic pumps working non-stop around the globe. With operating pressures up to 16 bar and ow rates up to approximately 100 cubic metres/hour, Bredel hose pumps save time and money by successfully handling the toughest applications in a broad range of industries. Save time and money Chemical Corrosive acids and bases Water and Waste Treatment High maintenance...

Open the catalog to page 2

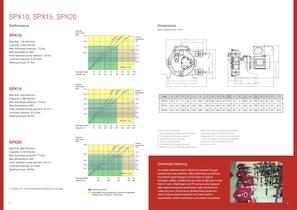

Inner diameter pump element: 10 mm Lubricant required: 0.25 litres motor power Inner diameter pump element: 15 mm Lubricant required: 0.5 litres motor power Inner diameter pump element: 20 mm Lubricant required: 0.5 litres motor power *Location is "E" noted on dimensional drawing on next page Continuous Duty Intermittent Duty (maximum 2 hours of operation followed by a minimum 1 hour stop 1. Flow required indicates pump speed 2. Calculated discharge pressure 3. Net motor power required 5. Calculated discharge pressure 6. Maximum recommended pump speed Note: The area of continuous operation...

Open the catalog to page 3

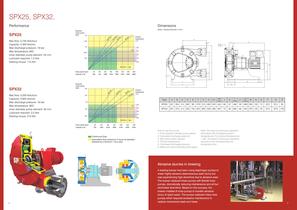

Inner diameter pump element: 25 mm Lubricant required: 1.5 litre motor power Inner diameter pump element: 32 mm Lubricant required: 3.5 litre motor power I Intermittent Duty (maximum 2 hours of operation followed by a minimum 1 hour stop 1. Flow required indicates pump speed 2. Calculated discharge pressure 3. Net motor power required 5. Calculated discharge pressure 6. Maximum recommended pump speed Note: The area of continuous operation diminishes with increased product temperatures. For product temperatures >40C, the area of continuous operation temperature line Abrasive slurries in...

Open the catalog to page 4

Inner diameter pump element: 40 mm Lubricant required: 5 litre Inner diameter pump element: 50 mm Lubricant required: 10 litre motor power motor power Intermittent Duty (maximum 2 hours of operation followed by a minimum 1 hour stop 1. Flow required indicates pump speed 2. Calculated discharge pressure 3. Net motor power required 5. Calculated discharge pressure 6. Maximum recommended pump speed Note: The area of continuous operation diminishes with increased product temperatures. For product temperatures >40C, the area of continuous operation temperature line A plant that produces fine...

Open the catalog to page 5

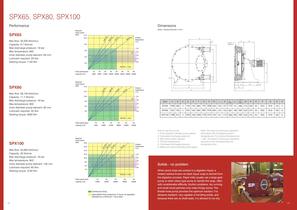

Inner diameter pump element: 65 mm Lubricant required: 20 litre motor power Inner diameter pump element: 80 mm Lubricant required: 40 litre motor power Inner diameter pump element: 100 mm Lubricant required: 60 litre motor power I Intermittent Duty (maximum 2 hours of operation followed by a minimum 1 hour stop 1. Flow required indicates pump speed 2. Calculated discharge pressure 3. Net motor power required 5. Calculated discharge pressure 6. Maximum recommended pump speed Note: The area of continuous operation diminishes with increased product temperatures. For product temperatures >40C,...

Open the catalog to page 6

Inner diameter pump element: 80 mm Lubricant required: 80 litre motor power Inner diameter pump element: 100 mm Lubricant required: 120 litre motor power I Intermittent Duty (maximum 2 hours of operation followed by a minimum 1 hour stop * For more information, please consult your Bredel representative. Duplex executions are also available Very limited floor space required. * This dimension will vary depending on drive selection. 1. Flow required indicates pump speed 2. Calculated discharge pressure 3. Net motor power required 5. Calculated discharge pressure 6. Maximum recommended pump...

Open the catalog to page 7

The SPX DuCoNite pump is used for the most challenging applications. A high-tech surface- protection method has rendered the pump ultra-resistant to aggressive liquids. The DuCoNite hose pumps are available in five pump sizes - with capacities up to The DuCoNite hose pump reliably handles a variety of harsh materials, such as sodium hypochlorite, titanium dioxide, sodium hydroxide, catalytic agents, sulfuric acid, lime slurry, acidic liquids, solvents and resins DuCoNite Advantage SPX hose pumps require minimal maintenance; to completely rebuild a SPX simply change the hose. When protecting...

Open the catalog to page 8

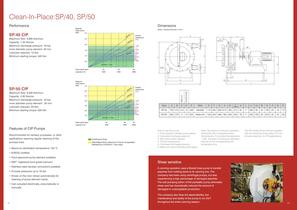

Dimensions Note: measurements in mm SP/40 CIP Maximum ow: 4,800 litre/hour Capacity: 1.33 litre/rev Maximum discharge pressure: 16 bar Inner diameter pump element: 40 mm Lubricant required: 10 litre Minimum starting torque: 320 Nm Maximum ow: 8,500 litre/hour Capacity: 2.92 litre/rev Maximum discharge pressure: 16 bar Inner diameter pump element: 50 mm Lubricant required: 20 litre Minimum starting torque: 620 Nm Recommended for sanitary processes, or other applications requiring regular cleaning of the process lines. Features of CIP Pumps • Maximum sterilization temperature 120 °C...

Open the catalog to page 9

Hose options The machined hose is the single most vital component for the performance, durability, and efciency of the hose pump. To ensure perfect compression and consistent, reliable performance, Bredel manufactures hoses from high quality compounded rubbers, reinforced with four individual layers of braided nylon and nished by high precision machining. Perfect compression eliminates slip which, in other pumps, can destroy shear sensitive product, reduce metering accuracy, or allow abrasive slurries to wreak havoc on wetted parts. Bredel engineers 1 Inner layer in various types of rubber...

Open the catalog to page 10All Watson-Marlow Fluid Technology Group catalogs and technical brochures

-

FC10/32

2 Pages

-

BREDEL HEAVY DUTY HOSE PUMPS

11 Pages

-

323U/D and 323U/4D

2 Pages

-

120 PERISTALTIC PUMPS

8 Pages

-

Flexicon brochure

13 Pages

-

Food and beverage brochure

7 Pages

-

MasoSine Certa brochure

7 Pages

-

Bredel heavy duty pumps

11 Pages

-

ASEPCO valves brochure

5 Pages

-

Aflex biotech brochure

7 Pages

-

Aflex industrial brochure

7 Pages

-

Close coupled pumps

8 Pages

-

Qdos brochure

7 Pages

-

Biopharm tubing

13 Pages

-

Biopharm overview

6 Pages

-

Tubing guide

15 Pages

-

Industrial overview

3 Pages

-

Corporate brochure

11 Pages

Archived catalogs

-

Bredel APEX 10, APEX15, APEX20

12 Pages

-

Sanitary process pumps catalog

20 Pages

-

Overview brochure

4 Pages

-

Qdos 30 overview brochure

12 Pages

-

300 and 400 series pumps

20 Pages

-

114 pumphead

2 Pages

-

720 SANITARY PUMPS

4 Pages

-

APEX hose pumps datasheet

2 Pages

-

MasoSine overview brochure

7 Pages

-

Flexicon

24 Pages

-

Aseptic Filling and capping

24 Pages

-

Close-coupled pumps brochure

8 Pages

-

Sanitary process pumps catalogue

20 Pages

-

OEM pumps

16 Pages

-

Hose pumps

12 Pages