Website:

WAGNER

Website:

WAGNER

Catalog excerpts

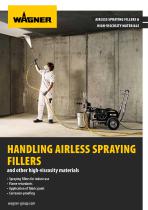

AIRLESS SPRAYING FILLERS & HIGH-VISCOSITY MATERIALS HANDLING AIRLESS SPRAYING FILLERS and other high-viscosity materials • Spraying fillers for indoor use • Flame retardants • Application of fabric paint • Corrosion-proofing

Open the catalog to page 1

Intelligent working for high profitability In the painting trade, there are many areas where it makes sense to use modern equipment technology – for example when applying varnishes, primers and emulsions. For some jobs, this technology is a must. These include large-area filler application as well as the application of fabric paints, flame retardants and corrosion-proofing products. Using WAGNER’s state-of-the-art airless units, these coatings can be applied evenly and quickly. The economic efficiency of equipment technology is an enormous advantage, in particular when handling...

Open the catalog to page 2

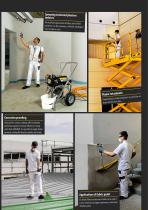

Spraying textured plasters indoors The machine application of fillers saves effor t and time. It is the economic, efficient, intelligen t way to work on-site. Flame retardants ly importa Fireproof ing is vital sites. large construction Corrosion proofing Only perfect surface coatings offer maximum protection against external influences. Using units from WAGNER, it is possible to apply homogeneous coating thicknesses quickly and easily. Application of fabric paint To attach fibrous material or fabrics to a wall, it is first necessary to apply a generous, even layer of fabric paint.

Open the catalog to page 3

High material usage A range of piston pumps are available for applying airless spraying fillers and other high-viscosity materials. Material Object size Flame retardant, corrosion proofing products, fabric paints Airless spraying fillers Structural waterproofing (bituminous coatings, thick coating materials) Equipment range WAGNER provides the ideal solution for handling high-viscosity materials. The advantages of our piston pumps lie in their high surface coverage and economic efficiency, due to the fact that less time and manpower are required. The high-quality finished surfaces are...

Open the catalog to page 4

ProSpray 3.39 fillers in detail Digi-Trac-Control No paint blockages The high-pressure filter can be accessed and cleaned quickly and easily. Three different filter pads (fine, medium, coarse) are available to meet the precise demands of the material. Optimized ergonomics With a 120°angle and weight of 780 g, the AG 19 is perfectly suited for highviscosity materials. The digital display makes it possible to read out and process machine data, consumption values, operating durations and much more information besides. Intelligent deadband control, SlowMotion function and Frequent-Clean...

Open the catalog to page 5

HeavyCoat - versatile and durable for demanding constru Spraying with quality with WAGNER’s professional AG 19 gun for high-performance applications. When used in combination with the 2SpeedTip nozzle for fillers, it is possible to handle even high-viscosity materials without difficulty. The integrated moun it possible to stow ho 60 m in length. SwingCart makes it possible to swivel the pump when working from a paint tin or container as well as during transport. HeavyCoat special hose with 3/8”, 1/2” or 3/4” cross-section for enhanced spraying performance. It is a quick and easy task to...

Open the catalog to page 6

Enhanced capacity with Special Spray Power for high viscosity materials WAGNER’s patented SSP system is a unique development for thehandling of high viscosity materials, such as airless spraying fillers, adhesive and bituminous coatings. The special design of the system ensures that the shovel piston continuously fills the pump with sufficient material. This permits trouble-free operation with no pulses. “Special Spray Power” is available for both HeavyCoat models. Decide for yourself just how much power you need. Extreme high-performance power packs thanks to hydraulic technology! The...

Open the catalog to page 7

Ideal for high viscosity materials The HeavyCoat variants 950 and 970 are available in a number of variants – petrol-driven or electric motor, with or without SSP. This means that operators can choose the perfect WAGNER Spraypack for them depending on the tasks they face. 01 - HeavyCoat 950 E/G Power pack for heavy materials 02 - HeavyCoat 970 E/G All-round Xtra speed for XL projects Versatile in use thanks to high delivery capacity The perfect choice for large areas and intensive usage Powerful but light: compact dimensions for ease of transport Optimum performance: with a delivery volume...

Open the catalog to page 8

03 - HeavyCoat 950 E/G with SSP Power pack for heavy materials. 02 - HeavyCoat 970 E/G with SSP All-round Xtra speed for XL projects Equipped with shovel piston for enhanced performance (SSP) Equipped with shovel piston for enhanced performance (SSP) Versatile in use thanks to high delivery capacity The perfect choice for large areas and intensive usage Powerful but light: compact dimensions for ease of transport Optimum performance: with a delivery volume of 12 l/min Innovative HeavyCoat product features: with a choice of either a petrol or electric motor which can be switched in a few...

Open the catalog to page 9

Our piston pump technology Piston pumps transport the material by means of a stroke movement in the piston. This creates high suction performance, making them ideal for highly viscous materials. Pneumatically driven piston pumps are explosion proof and therefore suitable for use in workshops. Our hydraulic piston pumps offer even greater performance and can also be operated with petrol. At a glance: benefits and applications Perfect for high-viscosity materials Optimal suction performance High delivery volumes, including with high-viscosity materials High material pressure: long hose...

Open the catalog to page 10

Airless filler accessories Airless guns Airless hoses, hose whips and reels High-quality, durable products for everyday work Robust, large-diameter high-pressure hoses AG 14; F-thread 1/4”; incl. TradeTip 3 nozzle holder (01) AG 19; 25 MPa; F-thread 1/4”; incl. TradeTip 3 nozzle holder(02) Pole gun 120 cm; 1/4” nozzle holder; F-thread 11/16” (03) Pole gun 200 cm; 1/4” nozzle holder; F-thread 11/16” Hose reel HR45; incl. 30 m HP hose DN6 All guns are also available with G-thread. For more information, visit www.wagner-group.com. Airless nozzles + holders Available in many different sizes A...

Open the catalog to page 11All WAGNER catalogs and technical brochures

-

Brochure PEM-X1 CG

4 Pages

-

Brochure Manual application

3 Pages

-

Corona and Tribo Guns

10 Pages

-

Brochure Cobra

4 Pages

-

Press release IceBreaker

3 Pages

-

STATIONARY Wood- & Metalworking

11 Pages

-

Manual powder coating

3 Pages

-

PXS Powder Centers

2 Pages

-

TOPFINISH DD10

2 Pages

-

FENCE & DECKING SPRAYER

36 Pages

-

C-Line

6 Pages

-

WOOD- & METALWORKING

12 Pages

-

Unica AME

4 Pages

-

Flyer EvoMotion-Revers AME

2 Pages

-

WAG Datenblatt DD10 GER

2 Pages

-

BROSCHÜRE COBRA AME

8 Pages

-

DD10

2 Pages

-

Control Pro 350 R

144 Pages

-

Control Pro 350 M

144 Pages

-

Control Pro 250 M

140 Pages

-

W 990 FLEXiO

122 Pages

-

W 950 FLEXiO

130 Pages

-

FineCoat 9900

6 Pages

-

FineCoat 9900 PowerCart

52 Pages

-

Zip 52

68 Pages

-

FinishControl 5000

132 Pages

-

FinishControl 3500

132 Pages

-

Basic Booth Systems

2 Pages

-

SuperCube

4 Pages

-

Prima Cube

4 Pages

-

ID-Booth System LV

4 Pages

-

Profi Tech M

8 Pages

-

Profi Tech S

6 Pages

-

Prima Tech CCM

4 Pages

-

Facades and interior walls

12 Pages

-

SuperFinish

5 Pages

-

Finish Control 5000

2 Pages

-

PROTEC GM

2 Pages

-

WOOD & METAL APPLICATIONS

7 Pages

-

BO AIRSPRAY-MANUAL AME

8 Pages

-

BO GM 4000AC AME WEB

8 Pages

-

BO AIRSPRAY-AUTOMATIC AME

2 Pages

-

SuperFinish SF 27

8 Pages

-

Finish 270

6 Pages

-

EPG_SL_5

2 Pages

-

TempSpray

6 Pages

-

PS 3.21 Spraypack

8 Pages

-

Finish 230 Lacquer Spraypack

2 Pages

-

PrimaTechCCM

4 Pages

-

profitech S

6 Pages

-

PrimaCube automatic system

4 Pages

-

BO Modular Painting System

4 Pages

-

SuperTech

4 Pages

-

ProfiTech

2 Pages

-

VertiCube

1 Pages

-

C4 HiCoat

4 Pages

-

PrimaTech Control Technology

4 Pages

-

Wagner Comfort Powder Centre

1 Pages

-

The C4 generation of guns

6 Pages

-

Inline pump IP5000

2 Pages

-

EPG-DP 5 Multi Control

2 Pages

-

DigiTech

2 Pages

-

Wagner 3D Pro Coating

1 Pages

-

Unica 4-270

4 Pages

-

TwinControl

8 Pages

-

SupraCoat

4 Pages

-

RoboCoat

2 Pages

-

IceBreaker®

8 Pages

-

WAGNER Thermo-technology

2 Pages

-

The WAGNER Thermo-System

2 Pages

-

GA 3000 AC

4 Pages

-

Evobell

4 Pages

-

Electrostatic guns

8 Pages

-

AirCoat guns

4 Pages

Archived catalogs

-

Cobra® 40-10

8 Pages

-

SuperCube_en

4 Pages

-

C4_brochure

4 Pages