Website:

Viking Pump

Website:

Viking Pump

Group: IDEX Corporation

Catalog excerpts

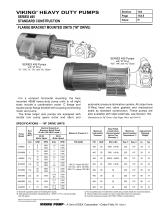

VIKING® HEAVY DUTY PUMPS Section Page SERIES 4195 STANDARD CONSTRUCTION SERIES 4195 Pumps Cutaway View “AS”, “AK”, “AL” SERIES 4195 Pumps Cutaway View “G”, “GG”, “H”, “HJ”, “HL” GPM up to 75 (M³/Hr up to 17) ② (Nominal Rating) BALL BEARINGS (Standard Equipment) Pumps are equipped with inner cas ing ball bearing installed outside of mechanical seal and a radial thrust ball bearing permitting heavy-duty service up to 250 PSI (17 BAR). Bearings are “Sealed for Life”. PRESSURE LUBRICATION (Standard Equipment) (“AS”, “AK”, “AL” Sizes) A patented pressure lubrication system automatically lubricates the idler bushing. This system provides a constant film of liquid between the idler bushing and idler pin at a pressure equal to the pump discharge pressure regardless of pump rotation. DUCTILE IRON PARTS (Standard Equipment) (“AS”, “AK”, “AL” Sizes) Internal pumping gears (rotor and idler) are constructed of ductile iron for added strength in handling all types of liquids up to 15,000 SSU (3,300 cSt). “HL” size rotor also furnished in ductile iron. O-RING GASKETS (Standard Equipment) O-Ring gaskets are used between casing and head plate and between casing and relief valve or valve plates. Flat valve gaskets furnished on “G”, “GG”, “H”, “HJ” and “HL” size pumps. These gaskets provide a positive seal eliminating a chance for leakage at these points. Viking’s high-speed, heavy-duty Series 4195 pumps are available in capacities up to 75 GPM. These pumps can be furnished directly connected to a 50 Hz or 60 Hz motor. (See Series 4195D units shown on page 144.3.) All eight sizes of Viking Series 4195 pumps are furnished with single mechanical seals. This seal is a simple selfadjusting, non-leak method of shaft sealing located ahead of the casing ball bearing. The Series 4195 pumps are built for coninuous or intermittent duty for t such applications as filtering, circulating, transferring, or booster service in general industrial, petroleum and marine uses. NOTE: “UL” listed pumps for handling LPGas require special construction. Externals are high strength cast iron. (Ductile Iron Casing on “AS”, “AK” and “AL” sizes). See Catalog Section 440 for details and pricing information. Model numbers for these pumps must be designated by a suffix -G, eg. GG4195-G or when used with a “D” drive, GG4195D-G. “UL” listed models must be equipped with a return-to-tank pressure relief valve. Maximum discharge pressure for “UL” listed models is 125 PSIG. ① Values shown represent minimums or maximums. Some special construcion or t consideration may be required before a cataloged pump can be ap lied to an p application involving maximum pressure or minimum or maxmum temperature i and/or viscosity. Certain models have restrictions in pressures and/or viscosities. See specifications, page 144.2, and perform nce curves, which can be a electronically generated with the Viking Pump Selector Program, located on www.vikingpump.com/pumpselector. ② Nominal capacities based on handling thin liquids. Metric conversions are based on US measurements and rounded to the nearest whole number. VIKING PUMP • A Unit of IDEX Corporation • Cedar Falls, IA

Open the catalog to page 1

Section Page VIKING® HEAVY DUTY PUMPS SERIES 4195 STANDARD CONSTRUCTION UNMOUNTED PUMPS MECHANICAL SEAL ① Buna-N bellows ② Buna-N O-ring ③ Carbon rotating face (washer) ④ Ni-Resist stationary seat ⑤ Steel metal parts ⑥ Stainless steel spring In addition to the famous features listed on the previous page, Series 4195 heavy-duty pumps are furnished with an integral relief valve as shown in the pump photos above. Return-to-tank valves are also available on all models on request. Note: On the “G”, “GG”, “H”, “HJ” and “HL” sizes, the valve mounts on the pump head. The “AS”, “AK” and “AL” size...

Open the catalog to page 2

VIKING® HEAVY DUTY PUMPS Section Page SERIES 4195 STANDARD CONSTRUCTION DIRECT DRIVE UNITS (“D” DRIVE) SERIES 4195 Pumps with “D” Drive “AS”, “AK” and “AL” Sizes with “D” Drive “G”, “GG”, “H”, “HJ” and “HL” Sizes Series 4195 pumps in the “G”, “GG”, “H”, “HJ” and “HL” size are designed for high-speed, heavy-duty service. The pump is connected by a flexible coupling with guard directly to a 50 Hz or 60 Hz motor. See series 4195D chart below. Both pump and motor mount on a sturdy formed steel base. This makes a very compact, rugged unit for heavy-duty ser ice, v handling many types of fluids...

Open the catalog to page 3

Section Page VIKING® HEAVY DUTY PUMPS SERIES 095C STANDARD CONSTRUCTION FLANGE BRACKET UNMOUNTED PUMPS ① Pressure Range Series 495 pumps are similar to the Series 4195 on preceding pages with the exception of a flange bracket mount casing. All eight sizes are furnished with single mechanical seals, including Buna-N elastomer gaskets. Standard construction features internal type safety relief valve on pump head or casing (depending on pump size), O-Ring head and valve gaskets, and automatic pressure lubrication system on the three larger size pumps. The 495 series offers an optional flange...

Open the catalog to page 4

VIKING® HEAVY DUTY PUMPS Section Page SERIES 495 STANDARD CONSTRUCTION FLANGE BRACKET MOUNTED UNITS (“M” DRIVE) with “M” Drive “AS”, “AK” and “AL” Sizes with “M” Drive “G”, “GG”, H”, “HJ” and “HL” Sizes For a compact horizontal mounting, the face mounted 495M heavy-duty pump units in all eight sizes inlude a combination motor “C” flange and c square pump flange bracket with coupling connecting motor and pump. The three larger size pumps are equipped with ductile iron pump gears (rotor and idler) and automatic pressure lubrication system. All sizes have O-Ring head and valve gaskets and...

Open the catalog to page 5All Viking Pump catalogs and technical brochures

-

OEM Custom Solutions

6 Pages

-

LVP Vane Pumps

8 Pages

-

Viking-Built Double Pumps

8 Pages

-

Dual Containment

1 Pages

-

855 Mag Drive Pumps

8 Pages

-

XPD Brochure

7 Pages

-

Motorspeed 2016 Infographic

2 Pages

-

Hygienic Series Poster

1 Pages

-

Hygienic Series

5 Pages

-

Viking Master Catalog Combined

560 Pages

-

4076, 4176

8 Pages

-

Metric Motor Speed

6 Pages

-

Universal Mag Drive

10 Pages

-

Universal Seal Pumps

16 Pages

-

Electric Heat

4 Pages

-

Viking Product Catalog

56 Pages

Archived catalogs

-

Composite Mag Drive

8 Pages

-

Gear Reducers

8 Pages

-

Power Load Monitors

2 Pages

-

SG External Gear Pumps

16 Pages

-

Lid-Ease® Basket Strainers

2 Pages

-

Universal Seal Pumps

16 Pages

-

Viking pump - Product Flyers

20 Pages