Website:

VELAN

Website:

VELAN

Catalog excerpts

Universal Steam traps For an extensive range of applications Pressure rating: up to 4000 psi.g NPS 3/8 – 3 (DN 10 – 80)

Open the catalog to page 1

VELAN COMPANY PROFILE Table of contents Product line A world-leading range of valves across all major industrial applications: •• Cast steel gate, globe, check, and ball valves •• Forged steel gate, globe, check, and ball valves •• Triple-offset butterfly valves •• Knife gate valves •• Severe service valves •• Bellows seal valves •• Steam traps Quality All major certifications and approvals •• ASME N stamp and NPT for nuclear valves (since 1970) •• ISO 9001 (since 1991) Currently certified to ISO 9001:2008 •• PED •• GOST (TR and RTN) •• API 6A and API 6D •• TA-Luft •• Quality programs fully...

Open the catalog to page 2

VELAN global network Head office • 16 production facilities • 5 plants in North America • 6 plants in Europe • 5 plants in Asia Montreal, Canada Velan Inc. • 5 stocking and distribution centers • Hundreds of distributors worldwide • Over 60 service shops worldwide Manufacturing Plants Distribution centers North America Montreal, Canada Velan Inc., Plant 1 Lyon, France Velan S.A.S. Ansan City, South Korea Velan Ltd., Plant 1 Granby, Canada VelCAN Montreal, Canada Velan Inc., Plant 2 and 7 Mennecy, France Segault S.A. Ansan City, South Korea Velan Ltd., Plant 2 Granby, Canada Velan Inc.,...

Open the catalog to page 3

metal comprising two or more metallic layers with different coefficients of expansion, which changes curvature when subjected to heat. Velan steam traps use a bimetal of high tensile strength, stable at high temperature with deflection limited to 600°F (315°C) to prevent over-stressing in super-heated steam service. what is bimetal? ●● Bimetal is a composite Deection & Pull The Original “multi-segmented” bimetal principle actuates Velan steam traps THE CLOSING FORCE OF THE BIMETALLIC ELEMENTs Follows the SATURATED STEAM curve Chart 1 illustrates the truly universal operating principle...

Open the catalog to page 4

principles of operation The Velan patented bimetal principle as applied to meet various requirements universal steam trap principle Chart 2 The patented multi-element principle. bar.g psi.g See page 4 for more details. Element closing forces Steam pressure closing force developed at saturated temperature in relation to the line pressure tending to open the valve. The gradual increase in force, following the steam curve, is a function of the patented segmentation principle of the element. The delicate balance of opening and closing forces exists in all pressure ranges such as 0-200, 0-350,...

Open the catalog to page 5

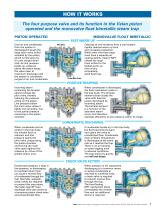

how it works The four purpose valve and its function in the Velan universal bimetallic steam trap fast warm up positive trapping The discharge valve is open, allowing air and cold water to be discharged rapidly. The period of waiting to start a process is reduced to minutes—there is no air binding, water-logging, or steam locking to delay equipment warm up. Incoming steam causes the bimetal to deflect. This thermal pull of the bimetal element acts on the valve stem, overcoming the steam pressure closing the valve. The ball valve is pulled tightly on to its seat, preventing weeping and loss...

Open the catalog to page 6

how it works The four purpose valve and its function in the Velan piston operated and the monovalve float bimetallic steam trap piston operated monovalve Float bimetallic fast warm up Cool air and condensate from the system is discharged through the large main valve orifice actuated by the piston, which is held open by it’s own weight when cold. As line pressure builds up, pressure above the piston keeps the valve open at maximum discharge until the system is completely purged of air and condensate. Clearing air and moisture from a cold system rapidly reduces warm up time and increases...

Open the catalog to page 7

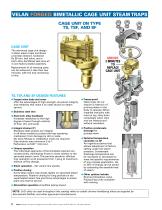

VELAN forged bimetallic cage Unit steam traps Cage unit on type ts, tsf, and sf Cage Unit The advanced cage unit design in Velan steam traps combines a bimetal element, hardened Rc 58 min. ball valve, and a CoCr alloy hardfaced seat area all in one factory-tested assembly. SERVICE: 2 MINUTES TO REPLACE CAGE UNIT Replacement of all wearing parts can be achieved in less than two minutes, with the trap remaining in-line. ts, tsf, and sf Design Features ●● Forged valve body and cover offer the advantages of high strength, structural integrity and reliability that make it an ideal choice for...

Open the catalog to page 8

VELAN forged TS steam traps E Standard materials MATERIALS Forged carbon steel A 105 (C. Max. 0.25) Same as body material Truflex GB-14 SS 316 core with graphite seal Chrome moly. alloy B7 Stainless steel SS, ball valve 58 Rc min. SS 316 core with graphite seal Stainless steel Stainless steel Stainless steel Carbon steel Body Cover Bimetal element Cover gasket Cover bolt Strainer Stem and ball Cage unit gasket Self-lock adjusting nut Fixing screw Bimetal holder (1) Plug 3/8 NPT Boiler headers, steam mains, branch lines, tracer lines, sterilizers and finned radiation. Connections ●● Screwed...

Open the catalog to page 9

VELAN forged TSF steam traps E Standard materials MATERIALS Forged carbon steel A 105 Body (C. Max. 0.25) Cover Same as body material Bimetal element Truflex GB-14 SS 321 spiral wound Cover gasket with graphite filler Cover bolt Chrome moly. alloy Strainer Stainless steel Stem and ball SS, ball valve 58 Rc min. SS 321 spiral wound Cage unit gasket with graphite filler Self-lock adjusting nut Stainless steel Fixing screw Stainless steel Stainless steel Bimetal holder (1) Plug 3/8 NPT Carbon steel Boiler headers, steam mains, branch lines and tracer lines. Screwed Socket-weld Butt-weld...

Open the catalog to page 10

VELAN forged SF steam traps E Standard materials PART A Body B Cover C Bimetal element D Cover gasket E Cover bolt(1) F Strainer G Stem and ball H Cage unit gasket I Self-lock adjusting nut J Fixing screw K Bimetal holder (2) L Plug 3/8 NPT MATERIALS Forged carbon steel A 105 (C. Max. 0.25) Same as body material Truflex GB-14 SS 316 core with graphite seal Chrome moly. alloy Stainless steel SS, ball valve 58 Rc min. SS 316 core with graphite seal Stainless steel Stainless steel Stainless steel Carbon steel Boiler headers, steam mains, branch lines, steam separators and intermediate stage...

Open the catalog to page 11All VELAN catalogs and technical brochures

-

Forged steel valves

28 Pages

-

General Purpose ball valves

8 Pages

-

Resilient-seated ball valves

44 Pages

-

Cryogenic Control Valves

6 Pages

-

Metal Seated Ball Valves

28 Pages

-

Complete Valve Solutions

16 Pages

-

Knife gate valves

20 Pages

-

Coker ball valves

8 Pages

-

Adareg control valves

8 Pages