Website:

USEON Technology Limited

Website:

USEON Technology Limited

Group: Useon Group

Catalog excerpts

Sheet Extrusion Lines Advanced Twin Screw Sheet/Film Direct Extrusion Technology Innovation creates advantage-higher quality, less energy consumption

Open the catalog to page 1

| Sheet Extrusion Lines Member of Useon Group Useon-Manllen (Shanghai) Plastic Machinery Co.,Ltd. was formed by Useon (Nanjing) Extrusion Machinery Co.,Ltd. and Shanghai Manllen Plastic Machinery Co.,Ltd. Useon-Manllen aims at high-end sheet/film production lines with advanced solution. Useon has acquired profound know-how in extruder design and its application; while Manllen has wealthy experience in practice and integration of sheet/film production line. This strong alliance has integrated the innovation platform of each other so that the innovation pace has been increased. End customers...

Open the catalog to page 2

Undried PET/PC sheet extrusion line Twin screw extruder has unique merits to the process of polyester resins. Polyester is very vulnerable to thermal decomposition and hydrolyzation. Useon-Manllen has launched newly high-torque, lower-shearing and low-temperature twin screw extruder for PET process, which streamlined the process, and portrayed advantages in energy-saving and end product quality. As a result, the whole production cost has been contained. Energy-saving: twin screw extruder direct extrusion technology eliminated the necessity of pre-drying of polyester, thus the electricity...

Open the catalog to page 3

PP Vacuum Shaping Sheet Production Line As per different application, PP sheet has to stuff some filler such as talc to improve its physical property or reduce cost In traditional process method, PP has to be compounded with filler, then pelletizing.Twin screw direct extrusion technology combines masterbatch preparation and mold extrusion together. The nature of inline compounding makes recipe change more flexible than ever, and makes the masterbatch preparation unnecessary. To learn more about the benefits of twin screw direct extrusion please refer to the 1st page. PLA/PBS+Starch...

Open the catalog to page 4

WPC One-step Sheet Production Line WPC (Wood Plastic Composite) sheet/board production lines get the most out of the benefits of twin screw direct extrusion technology. Besides the general benefits, what is more important the natural color and fiber have been saved at the best, not only does our low-temperature and low-shearing extruder design contribute, but the innovative process flow takes credit as well. Due to the wooden powder has been fed through the side feeder where the plastics are already in molten condition, thus the temperature setting can be lower than convey zone. As a...

Open the catalog to page 5

PVC/WPC/PP Foam Sheet Line Applying twin screw extruder into foam extrusion is Useon-Manllen's traditional advantage. No matter physical foam or chemical foam, twin screw extruder has its unique cutting edge. Its excellent mixing and dispersing effect can save additives up to 20%. Meanwhile, the product inner quality has been brought up. To learn more about the benefits of twin screw direct extrusion, please refer to the 15t page. PVB/EVA+starch film production involves many sorts of additives. Therefore, it requires good mixing and dispersing ability of extruder. The prominent mixing and...

Open the catalog to page 6

The board/sheet/film extrusion system or complete production lines delivered by Useon-Manllen covers most of the plastic board/sheet/film products. Let our expertise help you succeed. Choose your product ABSHIPS/PMMA board production line ABS/TPO/EVA/EPDM/PP/PE board production line APET/PETG/CPET/PLA sheet production line PC/PMMA/PS/MS board production line PC/PP/PE hollow grid sheet line PMMA/GPPS mirror sheet line PP/PE/ABS great thick board PP/PS vacuum shape packaging sheet line PP stationery print sheet line PP/PE/PS/EVA/EVOH multi-layer barrier sheet line WPC/PVC crust foam...

Open the catalog to page 7

B Polymer Compounding & Pelletizing for Color masterbatch and functional masterbatch Engineering plastic reinforcement Polymer alloy and compounding Polymer Foam Extrusion for Graphite EPS beads pelletizing Biodegradable foam product PE/PP/PETfoam sheet Twin Screw Direct Extrusion Sheet/Film Line for Undried PET/PC sheet PP vacuum shaping sheet EVA/PVB sheet PVC/WPC/PPfoam sheet PVC huge capacity sheet PE battery separator film R Polymer Recycling System for — EPS/XPS foam material recycling — PA/PP/PETfilament recycling — PE/PP/BOPP/BOPET film recycling Member of Useon Group

Open the catalog to page 8All USEON Technology Limited catalogs and technical brochures

-

Quality & Productivity

4 Pages

-

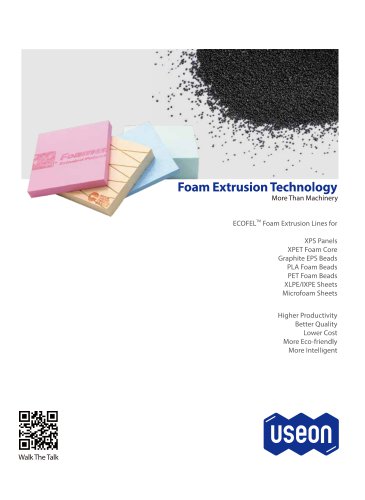

Foam Extrusion Technology

12 Pages

Archived catalogs

-

ECOFEL XPS Production Line

8 Pages

-

Foam Extrusion Lines

8 Pages

-

Extruders Brochure

12 Pages

-

SAT COMPOUNDER

16 Pages

-

xps production line-co2

6 Pages

-

Extruders

12 Pages

-

WPC Material Production Line

4 Pages

-

PET Extrusion Technology

6 Pages