Website:

USEON Technology Limited

Website:

USEON Technology Limited

Group: Useon Group

Catalog excerpts

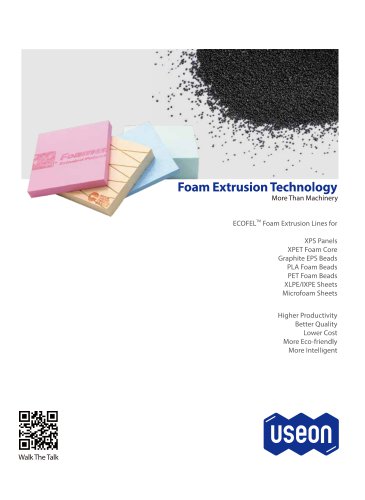

Newly ECOFELTM Polymer Foam Extrusion Lines Blowing agent conversion technology -Supercritical CO2 and portfolio Huge capacity polymer foam extrusion lines Full-automatic intelligent production lines

Open the catalog to page 1

Leading the way of innovation Useon has been engaged in polymer extrusion processing equipment R&D and manufacturing. From the first high torque twin screw extruder to the fastest EVA solar cell encapsulating film, and then the biggest China-made XPS production line, Useon has been leading the way of innovation. Aspiring Useon team enhances your competitiveness with our initiatives. More than a quality machine supplier, Useon is your reliable partner for long-term development. Green is the future Everyone on this planet has suffered the negative effect from climate change. Green way is...

Open the catalog to page 2

Full automatic feeding system Continuous and even feeding is a good beginning of excellent product. The recipe change can be done by digital setting screen. Raw material handling system can be customized according to individual factory circumstance. The whole feeding system is integrated so that the warehouse can be kept clean and tidy. Advanced twin screw technology Useon has introduced twin screw extruder into XPS production successfully. The introduction of a twin screw extruder into XPS production is a significant development. The excellent dispersion and compounding performance of twin...

Open the catalog to page 3

Innovative high-efficiency single screw cooling extruder It is well-known that the cooling is very critical for XPS production. We developed special cooling channel for the barrel of single screw cooling extruder which not only increase the cooling efficiency but also control the temperature more accurate and precise. Yet, it optimizes the cooling process and enough pressure gradients for CO2 foam extrusion. This combination is a result of USEON’s profound understanding of extruders and long-term research in this field.

Open the catalog to page 4

Supercritical CO2 metering system Metering supercritical CO2 continuously and evenly is one of the most challengeable works. It involves precise temperature control, pressure control, mass flow control and correlation with other processing parameters. The operation window of CO2 foam is narrower than traditional HCFCs so that the CO2 injection is very critical. Our CO2 convey and metering system can provide constant quantity and stable pressure CO2 injection. Full automatic downstream Vacuum raw material transport, loss-in-weight feeding, four-side edge trimming, online printer, online...

Open the catalog to page 5

Intelligent Control System From data access to recipe management, from operation log to alarm annotation, from peripherals extend to Ethernet or internet diagnose, our control system provides you a full-automatic and intelligent production line, yet help you manage the production. Friendly HMI makes the operation easier than ever. Rich experience in projection fulfillment Useon has abundant experience in cooperation with international groups and institute which help us know the strict details of machines’ stability, safety and humanization setting. Especially in huge capacity XPS line,...

Open the catalog to page 6

Lab for foam extrusion In order to cooperate with customers to develop new material and new recipe or new process, we launched our own polymer foam extrusion lab center. The lab center has one set of foam extrusion use twin screw extruder and some accessories. You don’t have to be bothered to find a foam extrusion lab machine; our well-equipped lab center is yours too. And our professionals would like to join you to develop new recipe and new process. Useon has been engaged in polymer extrusion equipment and process. Today, Useon becomes a leading supplier of polymer extrusion equipment....

Open the catalog to page 7

n High torque twin screw extruder — Masterbatch preparation/filling — Reaction/devolitilization extrusion — Engineering plastic modification n Polymer foam extrusion — C02 foam XPS production line — PP/PE foam extrusion — Other polymer foam extrusion n Direct extrusion technology — Pre-dry-free direct extrusion (PET, PC, PA, PBT etc.) — Inline compounding direct extrusion (EVA, PVB, UHWPE, polyolefin etc.) — Degradable stuff plus starch direct extrusion (PLA, PBS etc.) Direct Extrusion Useong (Nanjing) Extrusion Machinery Co.,Ltd. Address: No. 86, Fengze Road Gaoqiaomen Industry Zone,...

Open the catalog to page 8All USEON Technology Limited catalogs and technical brochures

-

Quality & Productivity

4 Pages

-

Foam Extrusion Technology

12 Pages

Archived catalogs

-

Sheet Extrusion Lines

8 Pages

-

Foam Extrusion Lines

8 Pages

-

Extruders Brochure

12 Pages

-

SAT COMPOUNDER

16 Pages

-

xps production line-co2

6 Pages

-

Extruders

12 Pages

-

WPC Material Production Line

4 Pages

-

PET Extrusion Technology

6 Pages