Website:

UNIVER Group

Website:

UNIVER Group

Catalog excerpts

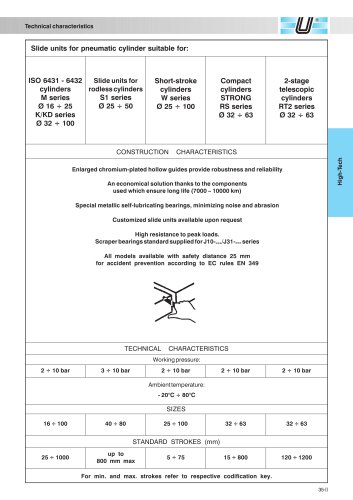

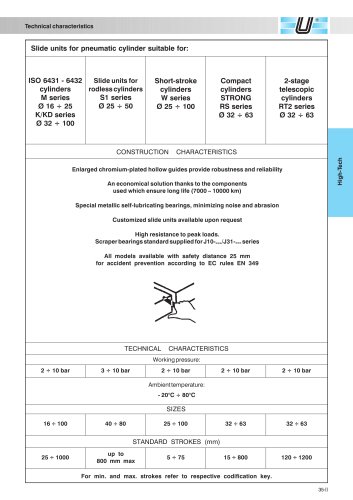

Technical characteristics Examination and verification of the cushioning a) decrease the load and maintain the translation speed above the curve, the cushioning beneath is not able to absorbe the kinetic energy the appropriate curve, the cushioning is ableto absorb the kinetic energy of the system. Vice versa if the point lies , in whichcase you must: b) decrease the speed and maintain the load In a system with moving masses, as in the case of rodless cylinders, it is essential to control the dissipation of thesystem's kinetic energy as it is brought to a stop. It is necessary, first of...

Open the catalog to page 3

Technical characteristics pneumatic cushion with electronic control;-a hydraulic cushion , available on the market.The mass movement generates loads to the cylinder, connected both to the weight forces (load values areconstant) and to the inertia forces which originate in the acceleration or deceleration phases of the piston at the beginning and at the end of the stroke.A typical fatigue stress arises in which the load value affects the life of the structure. The following acceptableloads refer to a life expectancy of 20000 km.The indicated values (in the corresponding pages of each series)...

Open the catalog to page 4

S101125 0850 M > CARRIAGE TYPE 0= Standard carriage > (for S5 series except 40 and 50 mm) 2= Medium carriage * 3= Long carriage * > LEFT END-CAP SUPPLY PORT 0= No supply port (when both chambers are suppliedfrom the right end-cap) 1= Side supply port * 2= Bottom supply port * 3= Rear supply port * Stroke (mm)Bore size (mm)Right end-cap supply port (dx)Left end-cap supply port (sx)Carriage typeSeries Option > RIGHT END-CAP SUPPLY PORT 1= Side supply port (twin ؘ 16 mm) 2= Bottom supply port * 3= Rear supply port (twin 16 mm) 4 = Both chambers supplied from the right end-cap > BORE SIZE 16 -...

Open the catalog to page 5All UNIVER Group catalogs and technical brochures

-

JLE

5 Pages

-

HZRS

2 Pages

-

MP Clamping cylinders

3 Pages

-

AC-N NAMUR valve

2 Pages

-

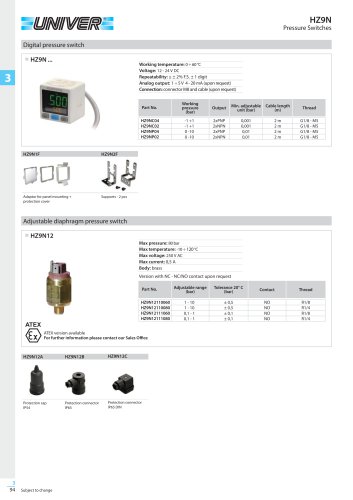

HZ9N

1 Pages

-

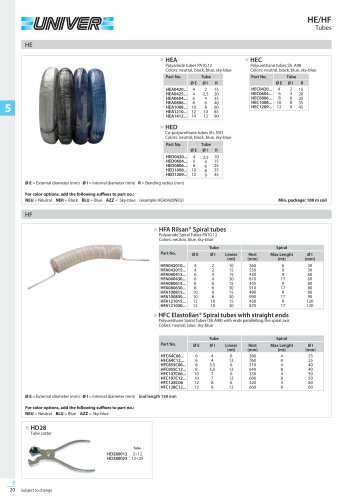

HE/HF tubes

1 Pages

-

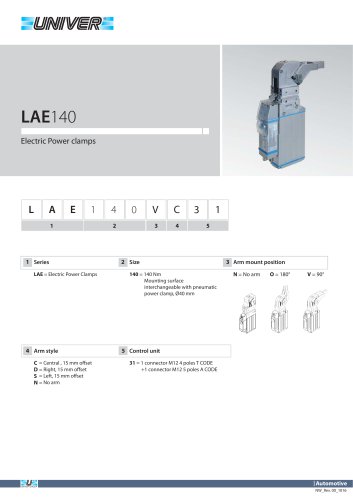

LAE140 Electric power clamps

4 Pages

-

Modular Tooling System - GR8

52 Pages

-

PRODUCT RANGE

44 Pages

-

ATEX PRODUCT RANGE

14 Pages

-

NEWS 2017-2018

32 Pages

-

NEWS 2016

16 Pages

-

PRODUCT OVERVIEW

228 Pages

-

Product range

44 Pages

-

ATEX Certified products

14 Pages

-

NEWS 2017

32 Pages

-

Valves

210 Pages

-

UBH40_UNIVERSAL Power clamps

6 Pages

-

PRODUCT RANGE

32 Pages

-

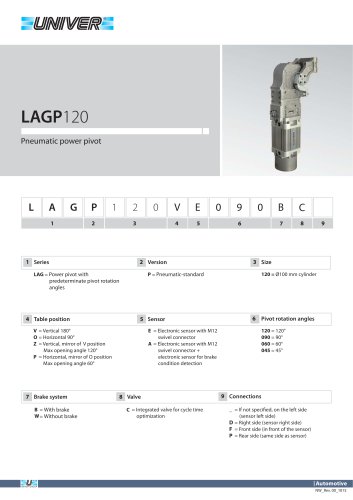

LAGP605_Pneumatic power pivot

13 Pages

-

LAGP600_Pneumatic power pivot

13 Pages

-

LAGP350_Pneumatic power pivot

13 Pages

-

LAGP300_Pneumatic power pivot

13 Pages

-

LAGP210_Pneumatic power pivot

13 Pages

-

LAGP170_Pneumatic power pivot

13 Pages

-

LAGP155_Pneumatic power pivot

13 Pages

-

LAGP150_Pneumatic power pivot

13 Pages

-

LAGP120_Pneumatic power pivot

13 Pages

-

LAGP080_Pneumatic power pivot

13 Pages

-

LAGP075_Pneumatic power pivot

13 Pages

-

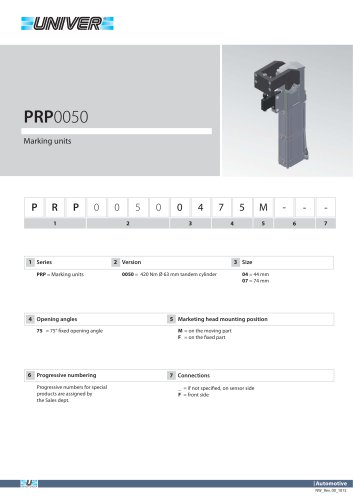

PRP1100_Marking units

3 Pages

-

PRP0500_Marking Units

4 Pages

-

PRP0050_Marking units

3 Pages

-

PRP0025_Marking units

2 Pages

-

LGP40_ Pneumatic Grippers

7 Pages

-

LGP32_ Pneumatic Grippers

7 Pages

-

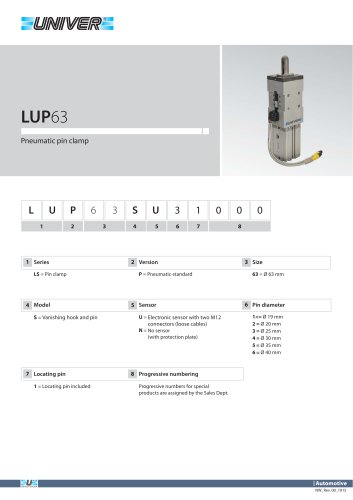

LUP63_Pneumatic pin clamp

2 Pages

-

LSP60_Pneumatic pin clamp

3 Pages

-

LSP50U_Pneumatic pin clamp

3 Pages

-

LSP32_Pneumatic pin clamp

3 Pages

-

IBM40_UNIVERSAL Power clamps

6 Pages

-

IBP40_UNIVERSAL Power clamps

6 Pages

-

UBH63_UNIVERSAL Power clamps

6 Pages

-

UBM40_UNIVERSAL Power clamps

6 Pages

-

UBM50_UNIVERSAL Power clamps

10 Pages

-

UBM63_UNIVERSAL Power clamps

10 Pages

-

UBM80_UNIVERSAL Power clamps

10 Pages

-

UBP32_UNIVERSAL Power clamps

4 Pages

-

UBP50_UNIVERSAL Power clamps

6 Pages

-

UBP63_UNIVERSAL Power clamps

6 Pages

-

UBP80_UNIVERSAL Power clamps

8 Pages

-

UBQ40_UNIVERSAL Power clamps

8 Pages

-

UBQ63_UNIVERSAL Power clamps

6 Pages

-

UBT40_UNIVERSAL Power clamps

6 Pages

-

AUTOMOTIVE DIVISION

24 Pages

-

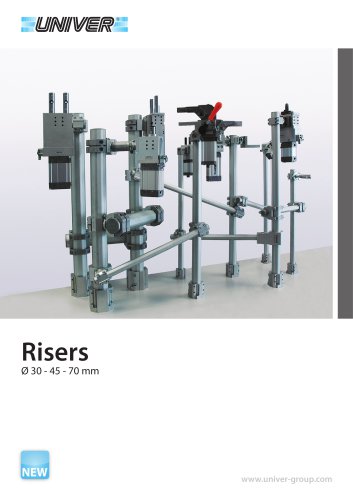

RISERS

4 Pages

-

LGP32-40 Pneumatic Grippers

16 Pages

-

GR8-Modular Tooling System

44 Pages

-

M series

1 Pages

-

Product Overview

228 Pages

-

POWER PIVOTS

2 Pages

-

PIN CLAMPS

2 Pages

-

CLAMPS

2 Pages

-

ACCESSORIES

54 Pages

-

AIR TREATMENT

14 Pages

-

HIGH TECH

75 Pages

-

CYLINDERS

67 Pages

-

KE_Cylinders according to ISO 15552

10 Pages

-

HZE_Additional components

4 Pages

-

HZE_Air treatment units

14 Pages

-

L1/L6_Locking unit for cylinders

6 Pages

-

HZE_Air treatment units

12 Pages

-

fittings

36 Pages

-

PS_COMBOBOX valves

12 Pages

-

AI_Miniature limit switches

4 Pages

-

CH_2/2 - 3/2 G1/8 poppet valves

4 Pages

-

A_15 mm Microvalves

6 Pages

-

B10_Nanovalvole 10 mm ISO 15218

2 Pages

-

OV_Oval cylinders Ø 18-80 mm

5 Pages

-

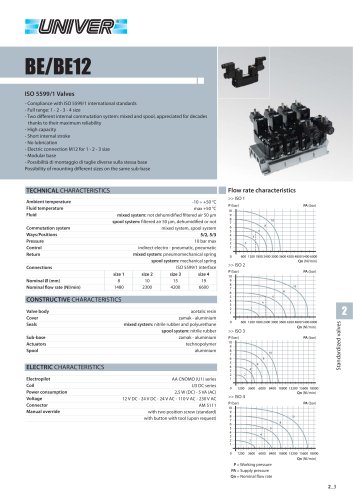

BE/BE12_ISO 5599/1 Valves

12 Pages

-

Rotary actuators Ø 32-125 mm

3 Pages