Website:

UNIVER Group

Website:

UNIVER Group

Catalog excerpts

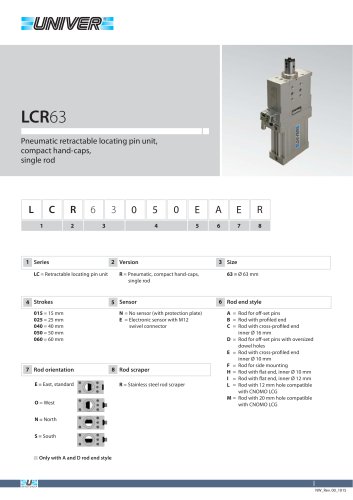

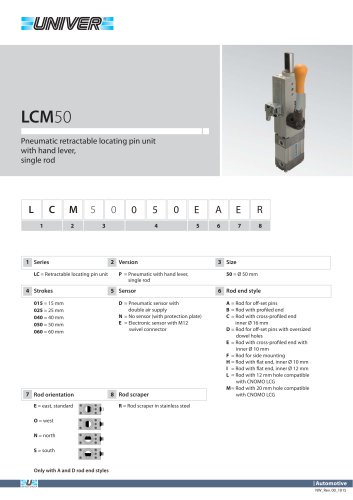

Pneumatic retractable locating pin units The handling, positioning as well as the maintenance operations have to be carried out by observing all conditions which guarantee the security of the staff and only by authorized personnel.The residual risks regarding the sole maintenance phase consist in the squashing of the upper parts of the operator's body. As a preventive measure an appropriate signalling or an adequate security system placed near the dangerous areas and which have to be installed by the user will alert the operator. The fixing of the unit to the equipment can be carried out by using the front, or side part of the housing of the clamp. Before installing the retractable locating pin unit, make sure that it hasn't been damaged during transport or handling operations. - Insert two hardened and grinded 08H7 pins into the special seats such as to locate the clamp - Fix it steadily by using the indicated M8 screws, and make sure that they are about 8 mm deep in the thread holes, limiting the tightening > Instructions for the connection of the clamp to its energy source Connect the sensor of the clamp to its electric supply unit. Then connect the pneumatic tube by means of suitable pneumatic fittings according to the specification below: Operating pressure from 4 to 8 bar ELECTRIC FEATURES Supply voltage Supply current without load Rated operational current Output logic Mole contacts Micro C Ml 2

Open the catalog to page 1

How to orientate the connector 1. Unscrew the screw of the connector 2. Open the cover 3. Rotate the connector 4. Close the cover and screw it How to replace the sensor 1. It is not necessary to remove the air supply 2. Unscrew the sensor’s screw 3. Insert a new sensor 4. Screw the sensor to its housing > Type and frequency of controls and/or maintenance work The unit has been designed and constructed in such a way that specific programmed maintenance is not necessary; anyway, a monthly external cleaning of the welding deposits with suitable, not aggressive and not corrosive detergents is...

Open the catalog to page 2All UNIVER Group catalogs and technical brochures

-

JLE

5 Pages

-

HZRS

2 Pages

-

MP Clamping cylinders

3 Pages

-

AC-N NAMUR valve

2 Pages

-

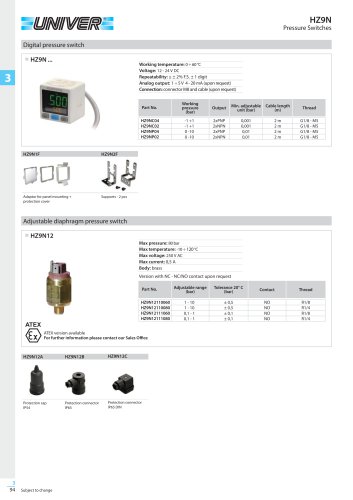

HZ9N

1 Pages

-

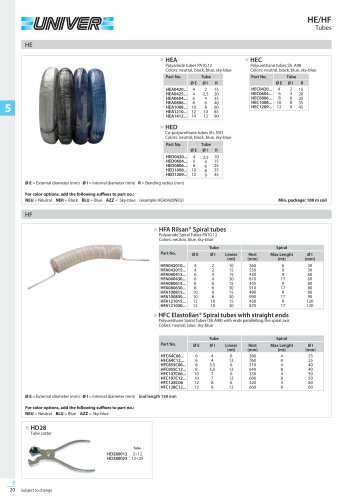

HE/HF tubes

1 Pages

-

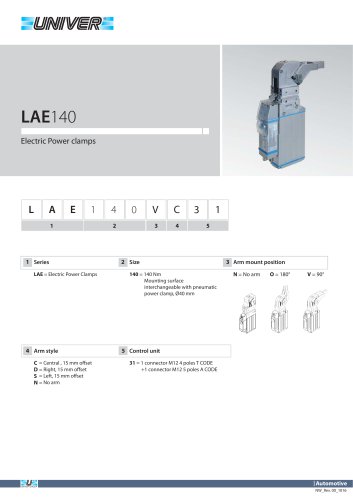

LAE140 Electric power clamps

4 Pages

-

Modular Tooling System - GR8

52 Pages

-

PRODUCT RANGE

44 Pages

-

ATEX PRODUCT RANGE

14 Pages

-

NEWS 2017-2018

32 Pages

-

NEWS 2016

16 Pages

-

PRODUCT OVERVIEW

228 Pages

-

Product range

44 Pages

-

ATEX Certified products

14 Pages

-

NEWS 2017

32 Pages

-

Valves

210 Pages

-

UBH40_UNIVERSAL Power clamps

6 Pages

-

PRODUCT RANGE

32 Pages

-

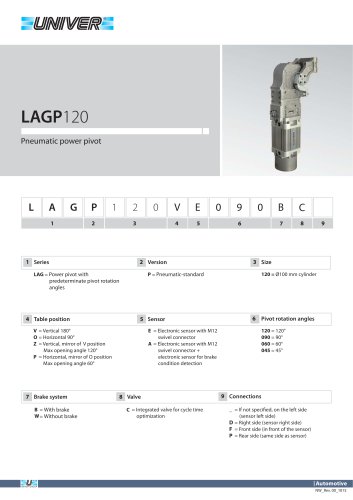

LAGP605_Pneumatic power pivot

13 Pages

-

LAGP600_Pneumatic power pivot

13 Pages

-

LAGP350_Pneumatic power pivot

13 Pages

-

LAGP300_Pneumatic power pivot

13 Pages

-

LAGP210_Pneumatic power pivot

13 Pages

-

LAGP170_Pneumatic power pivot

13 Pages

-

LAGP155_Pneumatic power pivot

13 Pages

-

LAGP150_Pneumatic power pivot

13 Pages

-

LAGP120_Pneumatic power pivot

13 Pages

-

LAGP080_Pneumatic power pivot

13 Pages

-

LAGP075_Pneumatic power pivot

13 Pages

-

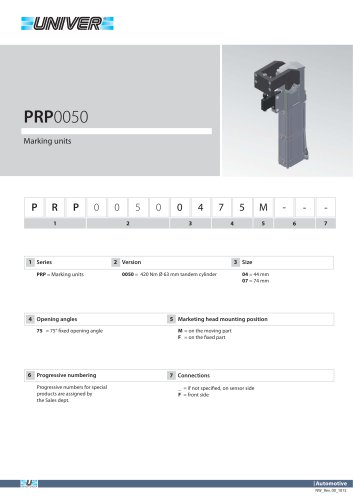

PRP1100_Marking units

3 Pages

-

PRP0500_Marking Units

4 Pages

-

PRP0050_Marking units

3 Pages

-

PRP0025_Marking units

2 Pages

-

LGP40_ Pneumatic Grippers

7 Pages

-

LGP32_ Pneumatic Grippers

7 Pages

-

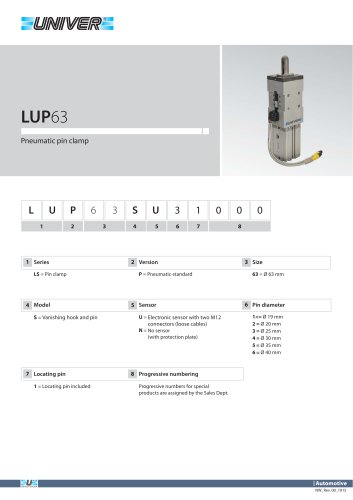

LUP63_Pneumatic pin clamp

2 Pages

-

LSP60_Pneumatic pin clamp

3 Pages

-

LSP50U_Pneumatic pin clamp

3 Pages

-

LSP32_Pneumatic pin clamp

3 Pages

-

IBM40_UNIVERSAL Power clamps

6 Pages

-

IBP40_UNIVERSAL Power clamps

6 Pages

-

UBH63_UNIVERSAL Power clamps

6 Pages

-

UBM40_UNIVERSAL Power clamps

6 Pages

-

UBM50_UNIVERSAL Power clamps

10 Pages

-

UBM63_UNIVERSAL Power clamps

10 Pages

-

UBM80_UNIVERSAL Power clamps

10 Pages

-

UBP32_UNIVERSAL Power clamps

4 Pages

-

UBP50_UNIVERSAL Power clamps

6 Pages

-

UBP63_UNIVERSAL Power clamps

6 Pages

-

UBP80_UNIVERSAL Power clamps

8 Pages

-

UBQ40_UNIVERSAL Power clamps

8 Pages

-

UBQ63_UNIVERSAL Power clamps

6 Pages

-

UBT40_UNIVERSAL Power clamps

6 Pages

-

AUTOMOTIVE DIVISION

24 Pages

-

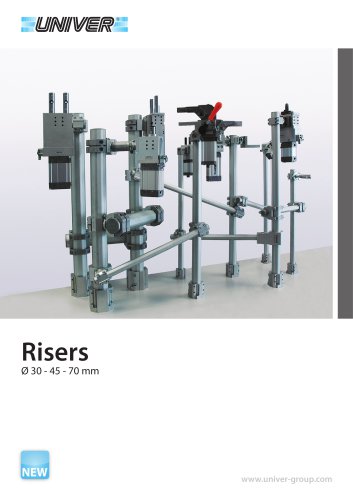

RISERS

4 Pages

-

LGP32-40 Pneumatic Grippers

16 Pages

-

GR8-Modular Tooling System

44 Pages

-

M series

1 Pages

-

Product Overview

228 Pages

-

POWER PIVOTS

2 Pages

-

PIN CLAMPS

2 Pages

-

CLAMPS

2 Pages

-

ACCESSORIES

54 Pages

-

AIR TREATMENT

14 Pages

-

HIGH TECH

75 Pages

-

CYLINDERS

67 Pages

-

KE_Cylinders according to ISO 15552

10 Pages

-

HZE_Additional components

4 Pages

-

HZE_Air treatment units

14 Pages

-

L1/L6_Locking unit for cylinders

6 Pages

-

HZE_Air treatment units

12 Pages

-

fittings

36 Pages

-

PS_COMBOBOX valves

12 Pages

-

AI_Miniature limit switches

4 Pages

-

CH_2/2 - 3/2 G1/8 poppet valves

4 Pages

-

A_15 mm Microvalves

6 Pages

-

B10_Nanovalvole 10 mm ISO 15218

2 Pages

-

OV_Oval cylinders Ø 18-80 mm

5 Pages

-

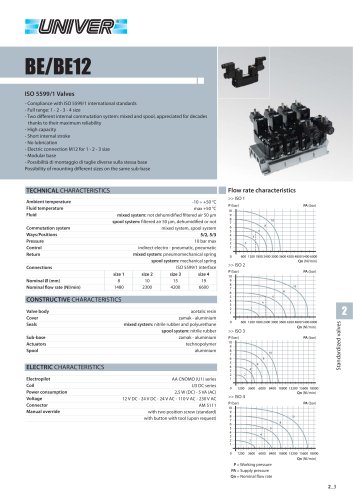

BE/BE12_ISO 5599/1 Valves

12 Pages

-

Rodless cylinders Ø 16-50 mm

12 Pages

-

Rotary actuators Ø 32-125 mm

3 Pages